Temperature stable vaccine formulations

A stable and vaccine technology, applied in the field of freeze-dried and frozen vaccine preparations, can solve problems such as loss of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

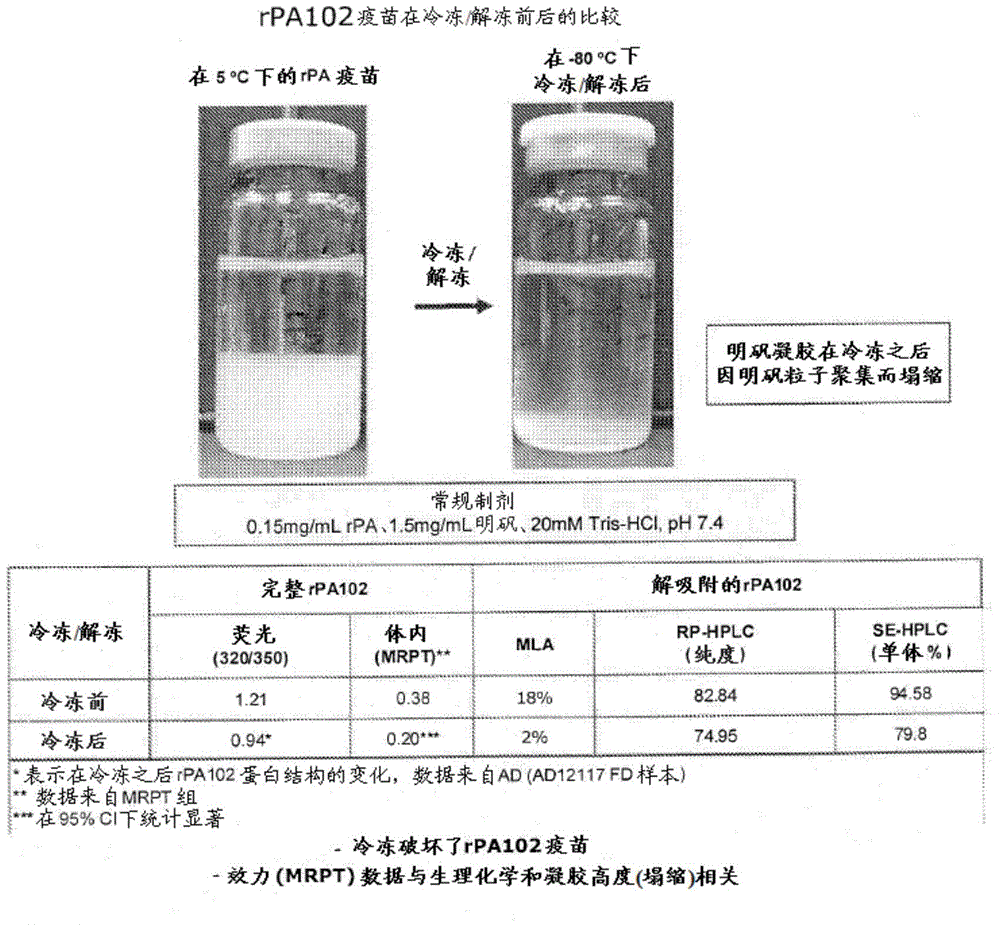

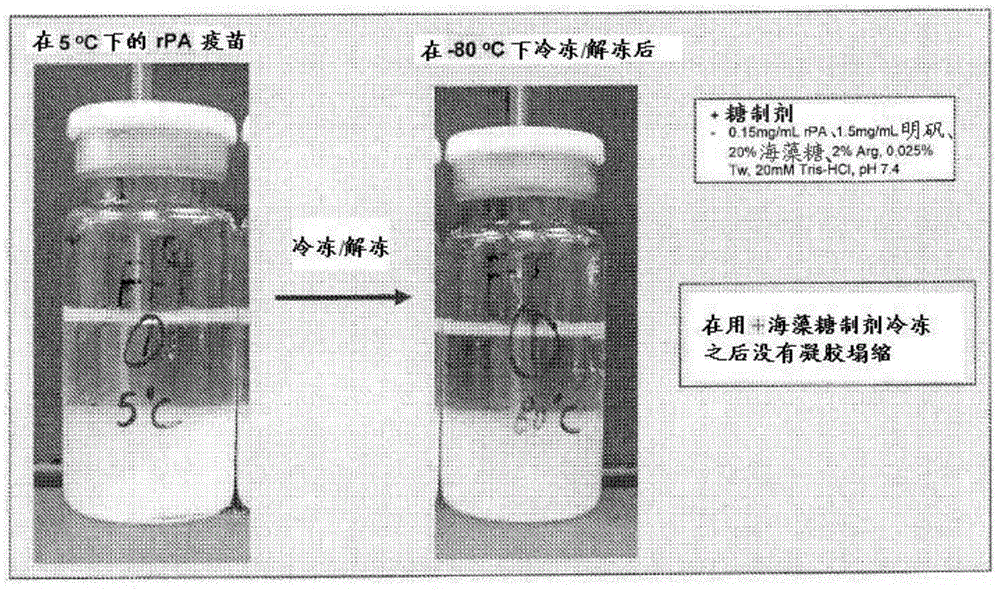

[0115] Example 1: Freezing / thawing of liquid rPA and AVA vaccines with and without trehalose

[0116] rPA102 vaccine formulations were prepared with and without trehalose as outlined in Table 1 below.

[0117] Table 1. Trehalose Preparations Used for Freeze / Thaw Analysis

[0118]

[0119] After compounding, each sample was divided into two 8ml aliquots in 10ml glass tubes. For each sample, one tube was placed at -80°C after gentle mixing overnight and the other tube was placed at 2-8°C after gentle mixing overnight.

[0120] Samples stored overnight at -80°C were thawed on the lab bench for several hours (>3-4 hours) the next day, then observed and compared to samples brought to room temperature at 2-8°C. Photograph the samples and measure the total liquid height and ALHYDROGEL (aluminum hydroxide) height. Comparison of conventional rPA102 vaccine before and after freezing / thawing. figure 1 are photographs comparing rPA Control 1 samples at 2-8°C (labeled ...

Embodiment 2

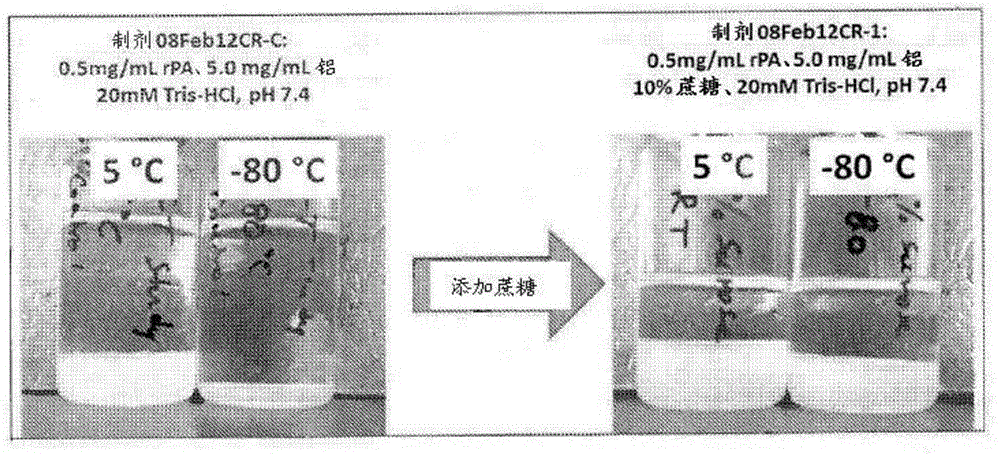

[0125] Example 2: Freezing / thawing of liquid rPA vaccines with and without sucrose

[0126] The rPA102 vaccine formulations were prepared with and without sucrose as outlined in Table 3 below.

[0127] Table 3. Sucrose preparations used for freeze / thaw analysis

[0128]

[0129] After compounding, each sample was divided into two 10ml aliquots in 10ml glass tubes. For each sample, one tube was placed at -80°C after gentle mixing overnight and the other tube was placed at 2-8°C after gentle mixing overnight.

[0130] Samples stored overnight at -80°C were thawed on the laboratory bench for 2-3 hours the next day before observation. image 3 Contains photographs of each formulation from 2-8°C (marked 5°C) and -80°C after both had reached room temperature. As shown, after thawing, gel collapse occurred in both -80°C samples (rPA Control 2 and rPA Test 2) compared to samples still refrigerated at 2-8°C. However, the amount of gel collapse was significantly gre...

Embodiment 3

[0131] Example 3: In Vivo Mouse Potency Analysis

[0132] Lyophilized vaccines were prepared as outlined in Table 4. The dried vaccine was reconstituted with water for injection to a final rPA concentration of 0.15 mg / ml (75 μg / 0.5 ml dose), followed by 10-fold dilution in saline to obtain a dose level of 0.1 (DL).

[0133] Female CD-1 mice, 5-8 weeks old and weighing 20-25 grams, were each used in this study. 0.1 DL vaccine (0.5 ml) was injected intraperitoneally into groups of 20 female CD-1 mice, and serum was collected on day 28 to assess neutralization of anthrax LT cells in mice in a toxin neutralization assay (TNA) The ability to be toxic.

[0134] Table 4. Lyophilized formulations used for mouse potency assays

[0135]

[0136] The immunogenicity of the rPA102 preparation was studied by calculating the neutralization factor (NF50). Neutralization factor NF50 is defined as follows:

[0137]

[0138] wherein the effective dose 50% (ED50) refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com