Passivation film, coating material, solar-cell element, and silicon substrate with passivation film attached thereto

A solar cell and passivation film technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of low cost, slow deposition speed of ALD method, and inability to obtain high production capacity, so as to achieve low cost and extended load capacity. The effect of carrier life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0065] The passivation film of this embodiment is a passivation film used for a silicon solar cell element, and contains aluminum oxide and niobium oxide.

[0066] By making the passivation film contain aluminum oxide and niobium oxide, the carrier lifetime of the silicon substrate can be extended, and it has negative fixed charges. Therefore, the passivation film of the present invention can improve the photoelectric conversion efficiency of a silicon solar cell element. Furthermore, since the passivation film of this invention can be formed by the coating method or the printing method, a film-forming process is simple, and the productivity of film-forming is high. As a result, pattern formation is also easy, and cost reduction can be achieved.

[0067] In addition, in the present embodiment, by changing the composition of the passivation film, it is possible to control the amount of fixed charges that the film has.

[0068] As a function of a general passivation film, ther...

Embodiment approach 2

[0078] The coating-type material of this embodiment contains an alumina precursor and a niobium oxide precursor, and this coating-type material is used for formation of the passivation film of the solar cell element which has a silicon substrate.

[0079] The alumina precursor can be used without any particular limitation as long as it can produce alumina. As the alumina precursor, it is preferable to use an organic alumina precursor from the viewpoint of uniformly dispersing alumina on the silicon substrate and from the viewpoint of chemical stability. As an example of an organic alumina precursor, aluminum triisopropoxide (structural formula: A1(OCH(CH 3 ) 2 ) 3 ), (Strain) High Purity Chemical Research Institute SYM-AL04, etc.

[0080] The niobium oxide precursor can be used without particular limitation as long as it can generate niobium oxide. As the niobium oxide precursor, an organic niobium oxide precursor is preferably used from the viewpoint of uniformly dispersi...

Embodiment approach 3

[0083] The solar cell element (photoelectric conversion device) of this embodiment has the passivation film (insulating film, protective insulating film) described in Embodiment 1 above, that is, a film containing aluminum oxide and niobium oxide, in the vicinity of the photoelectric conversion interface of the silicon substrate. . By containing alumina and niobium oxide, the carrier life of the silicon substrate can be extended, and it has negative fixed charge, so that the characteristics (photoelectric conversion efficiency) of the solar cell element can be improved.

[0084]

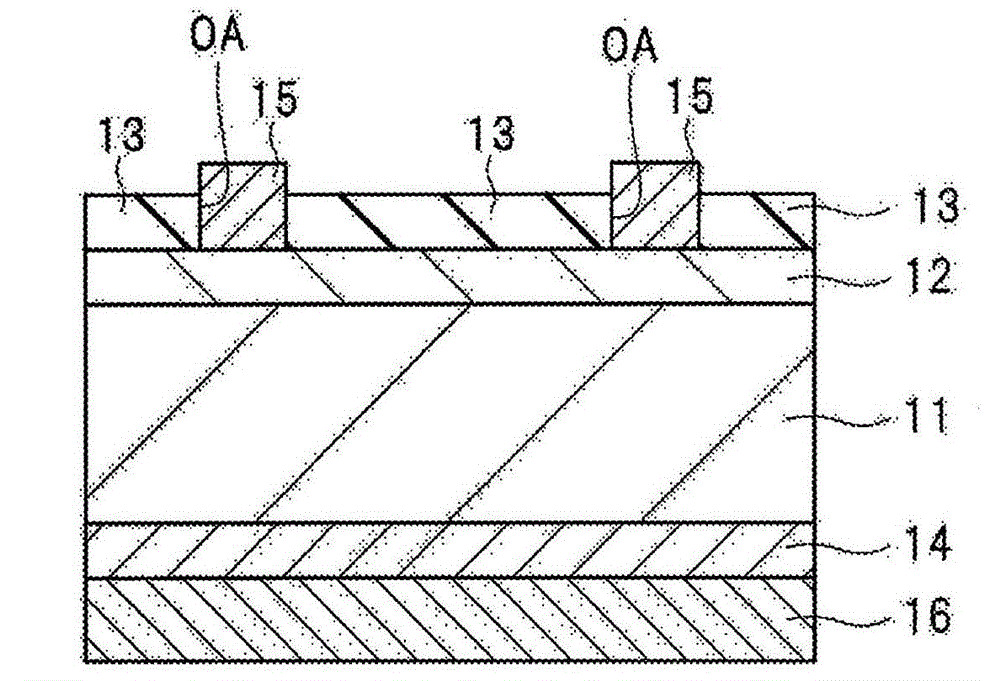

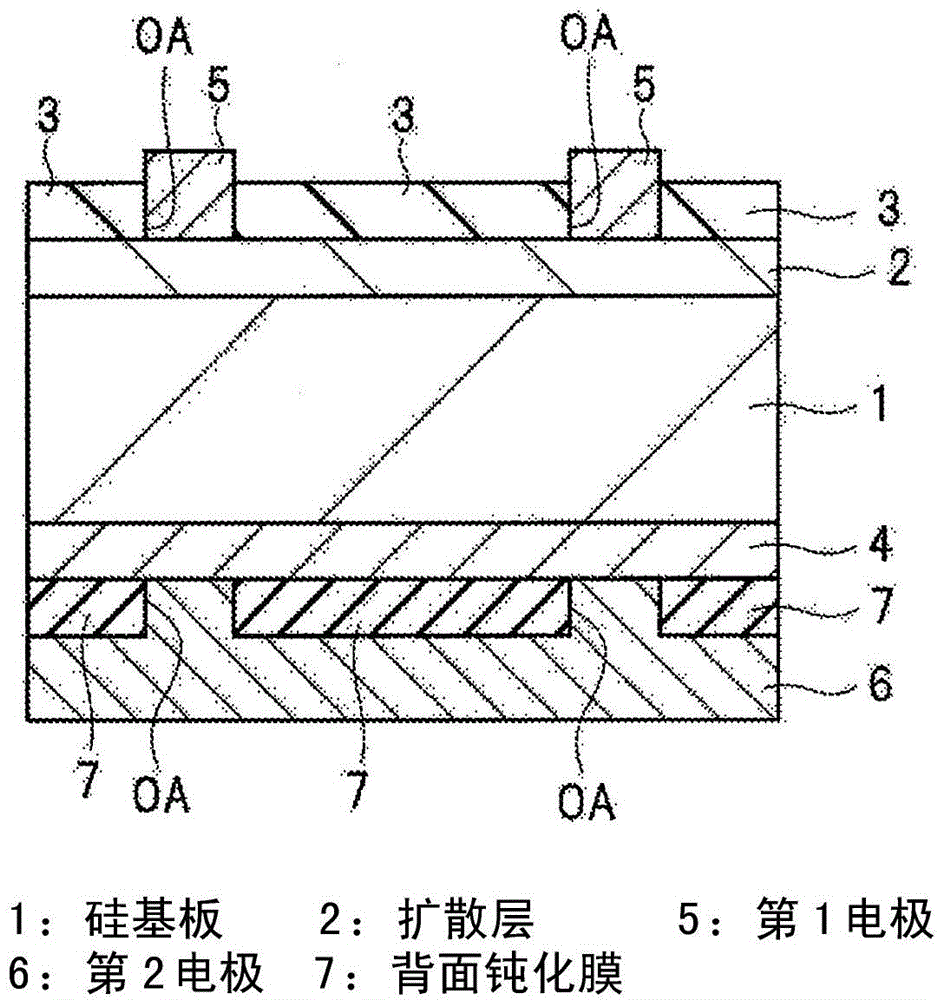

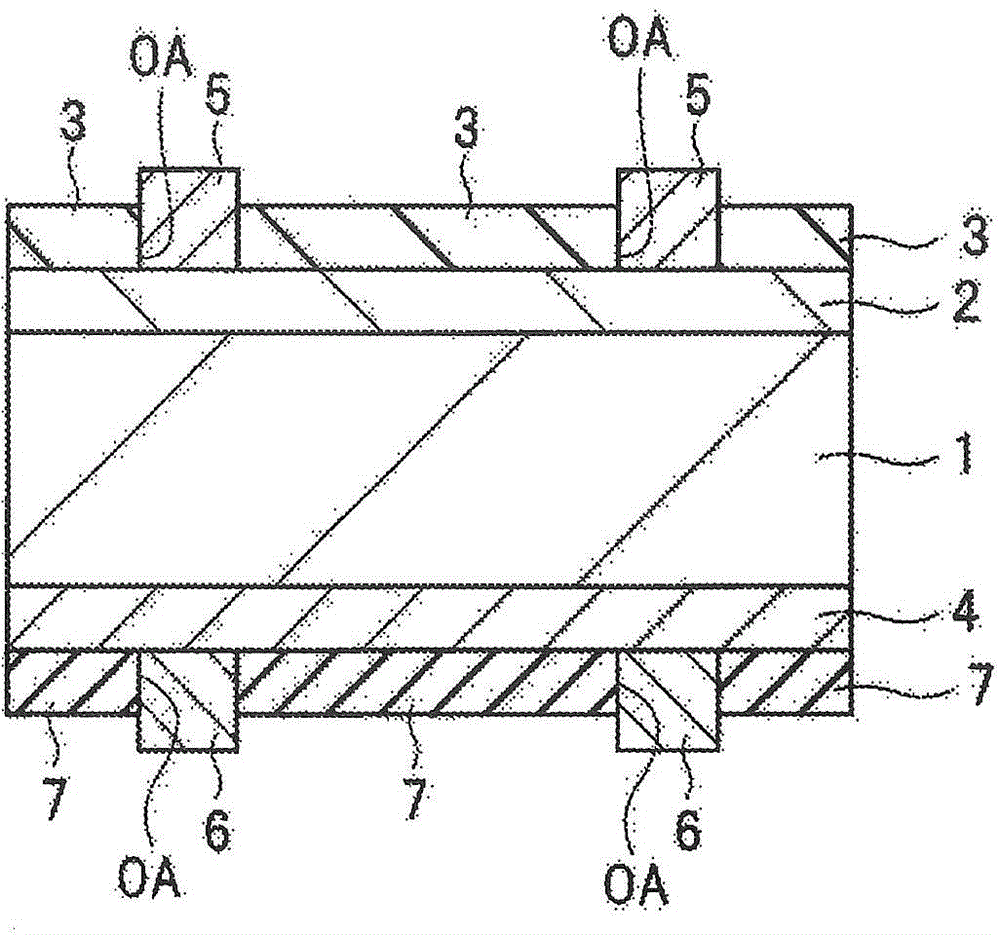

[0085] First, refer to Figure 2 to Figure 5 The structure of the solar cell element of this embodiment is demonstrated. Figure 2 to Figure 5 It is a sectional view which shows the 1st - 4th structural example of the solar cell element which used the passivation film on the back surface of this embodiment.

[0086] Either single crystal silicon or polycrystalline silicon can be used as the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com