Method for passivating perovskite thin film layer and perovskite solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems that do not take device stability into account, improve conversion efficiency and stability, simple and convenient method, and excellent stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

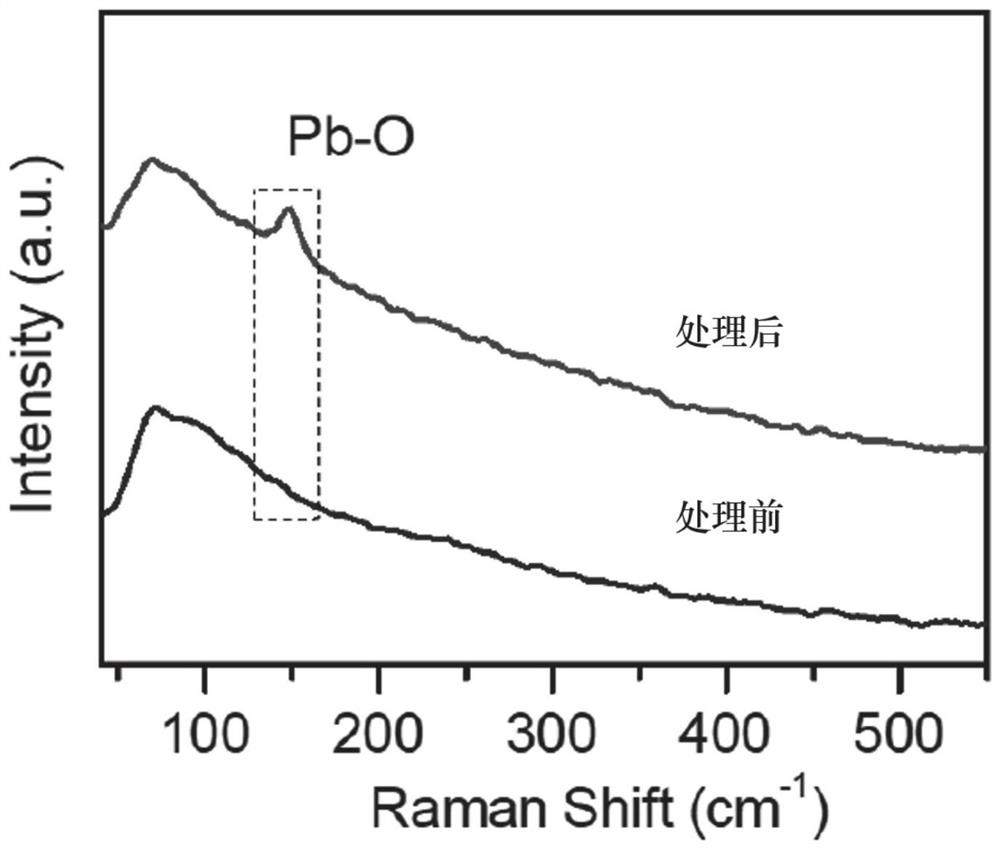

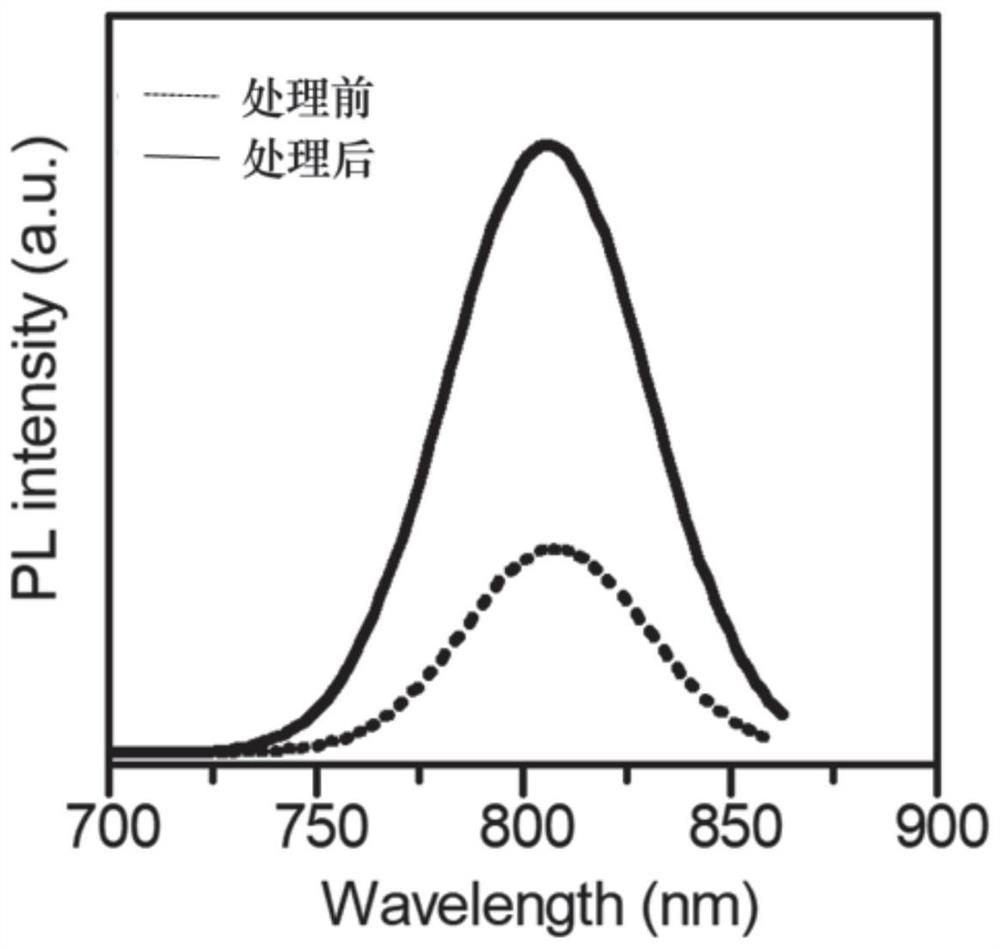

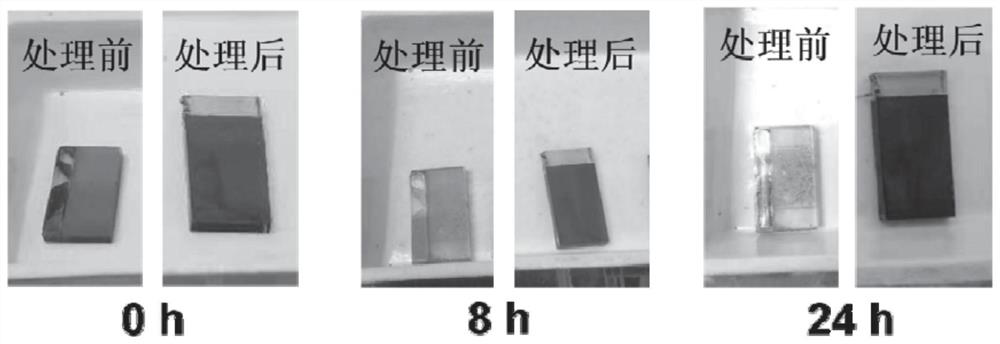

Method used

Image

Examples

Embodiment 1

[0054] According to the method provided by the present invention,

[0055] (1) PbI 2 , CsI, FAI and NMP (N-methylpyrrolidone) were dissolved in DMF (N,N-dimethylformamide) at a molar ratio of 1:0.03:0.97:1, and stirred continuously at 70°C for 1 hour, make it dissolve completely, and obtain FA with a concentration of 1.4mol / L 0.97 Cs 0.03 PB 3 Perovskite precursor solution;

[0056] (2) will be made of conductive glass / SnO 2 The substrate composed of two layers was annealed for 30 minutes under the condition of air atmosphere and 150°C, and the substrate was transferred to the glove box after the temperature dropped to room temperature;

[0057] (3) the FA 0.97 Cs 0.03 PB 3 The perovskite precursor solution was spin-coated on the above-mentioned substrate at a speed of 4000 rpm for 30 seconds, and then heated at 150°C containing FA 0.97 Cs 0.03 PB 3 Substrate the perovskite precursor solution for 20 minutes to generate black perovskite phase of FA 0.97 Cs 0.03 PB ...

Embodiment 2

[0067] (1) PbI 2 , CsI, FAI and NMP (N-methylpyrrolidone) were dissolved in DMF (N,N-dimethylformamide) at a molar ratio of 1:0.03:0.97:1, and stirred continuously at 70°C for 1 hour, make it dissolve completely, and obtain FA with a concentration of 1.4mol / L 0.97 Cs 0.03 PB 3 Perovskite precursor solution;

[0068] (2) will be made of conductive glass / dense ZnO-ZnS layer / mesoporous TiO 2 The substrate composed of two layers was annealed for 30 minutes in air atmosphere at 550°C, and the substrate was transferred to the glove box after the temperature dropped to room temperature;

[0069] (3) the FA 0.97 Cs 0.03 PB 3 The perovskite precursor solution was spin-coated on the above-mentioned substrate at a speed of 4000 rpm for 30 seconds, and then heated at 150°C containing FA 0.97 Cs 0.03 PB 3 Substrate the perovskite precursor solution for 20 minutes to generate black perovskite phase of FA 0.97 Cs 0.03 PB 3 Perovskite thin film;

[0070] (4) Pentafluoroaniline t...

Embodiment 3

[0078] (1) PbI 2 , CsI, FAI and NMP (N-methylpyrrolidone) were dissolved in DMF (N,N-dimethylformamide) at a molar ratio of 1:0.03:0.97:1, and stirred continuously at 70°C for 1 hour, make it dissolve completely, and obtain FA with a concentration of 1.4mol / L 0.97 Cs 0.03 PB 3 Perovskite precursor solution;

[0079] (2) will be made of conductive glass / SnO 2 The substrate composed of layers was annealed for 30 minutes in air atmosphere at 150°C. After the temperature dropped to room temperature, the substrate was transferred to a glove box, and the humidity was controlled at about 30%;

[0080] (3) the FA 0.97 Cs 0.03 PB 3 The perovskite precursor solution was dripped into the slit, and after scraping to form a film, the substrate was quickly vacuum flashed, and then annealed on a hot plate at 150°C for 20 minutes to form a black perovskite phase FA. 0.97 Cs 0.03 PB 3 Perovskite film, wherein the distance between the height of the scraper and the substrate is 100 μm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com