Method for prolonging minority carrier lifetime of silicon carbide epitaxial material

A minority carrier and epitaxial material technology, which is applied in the field of improving the minority carrier life of silicon carbide epitaxial materials, can solve the problems of complex process and material pollution, and achieve simple process, reduce etching effect, and eliminate carbon vacancies Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

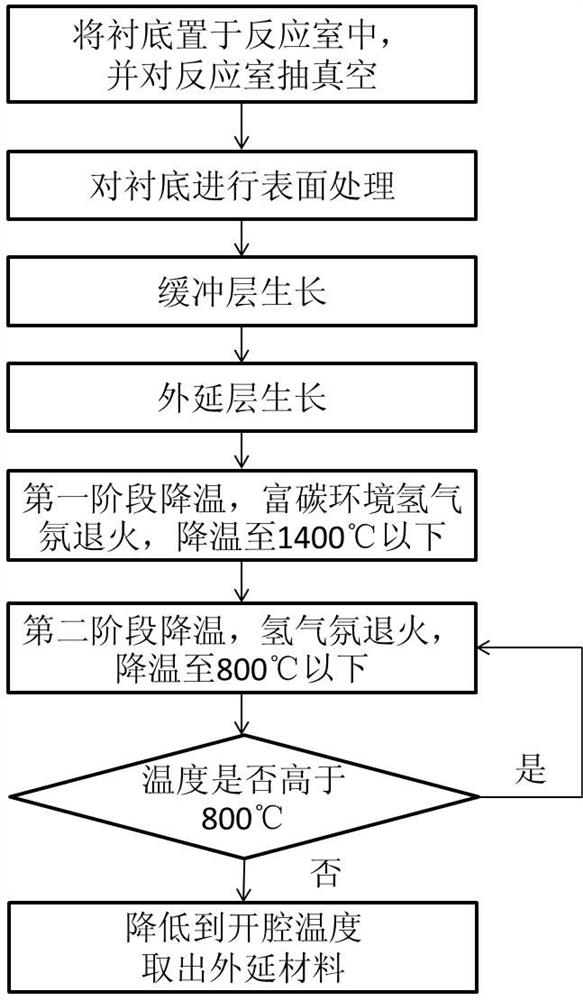

Image

Examples

Embodiment 1

[0029] Improve the minority carrier lifetime of 50 μm thick SiC epitaxial materials prepared on N-type SiC substrates (using ethylene, trichlorosilane and nitrogen as carbon source, silicon source and doping source respectively), such as figure 1 shown, including the following steps:

[0030] Step 1: Place the cleaned N-type SiC substrate into the reaction chamber of the SiC chemical vapor deposition equipment, and vacuumize the reaction chamber to a degree of 2×10 -3 mbar;

[0031] Step 2: Pass high-purity hydrogen into the reaction chamber, adjust the pressure of the reaction chamber to 80mbar, slowly increase the temperature to 1650°C, adjust the flow rates of ethylene, trichlorosilane and nitrogen to 18sccm, 75sccm and 250sccm respectively and set them as exhaust , keep the temperature for 5 minutes after the temperature stabilizes, and then perform surface treatment on the SiC substrate;

[0032] Step 3, keep the temperature and pressure of the reaction chamber constant...

Embodiment 2

[0039] Improve the minority carrier lifetime of 50 μm thick SiC epitaxial materials prepared on N-type SiC substrates, and use hydrogen chloride to assist in the treatment of the substrate surface (using ethylene, trichlorosilane and nitrogen as carbon sources, silicon sources and doping sources respectively ).

[0040] Step 1, place the cleaned SiC substrate into the reaction chamber of the SiC chemical vapor deposition equipment, and vacuumize the reaction chamber to a degree of 2×10 -3 mbar;

[0041] Step 2, feed high-purity hydrogen into the reaction chamber, adjust the pressure of the reaction chamber to 80mbar, slowly increase the temperature to 1650°C, and adjust the flow rates of ethylene, trichlorosilane, nitrogen and hydrogen chloride to 18sccm, 75sccm, 250sccm and 10sccm and set to exclude, after the temperature stabilizes, pass hydrogen chloride into the reaction chamber for 3 minutes, and perform surface treatment on the SiC substrate;

[0042] Step 3, keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com