Patents

Literature

37results about How to "Enhancing lifetime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic light emitting devices

ActiveUS20040209117A1Improve efficiencyEnhanced operational lifetimeOrganic chemistryDischarge tube luminescnet screensElectron injectionDisplay device

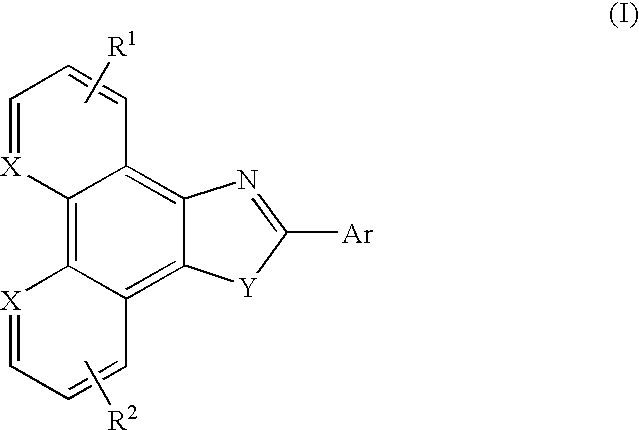

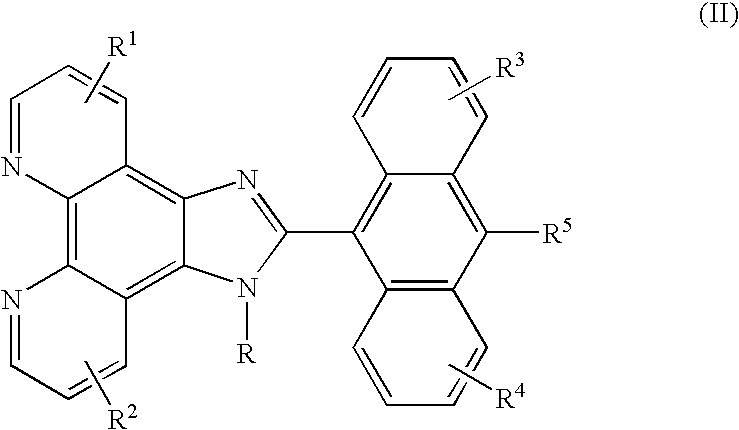

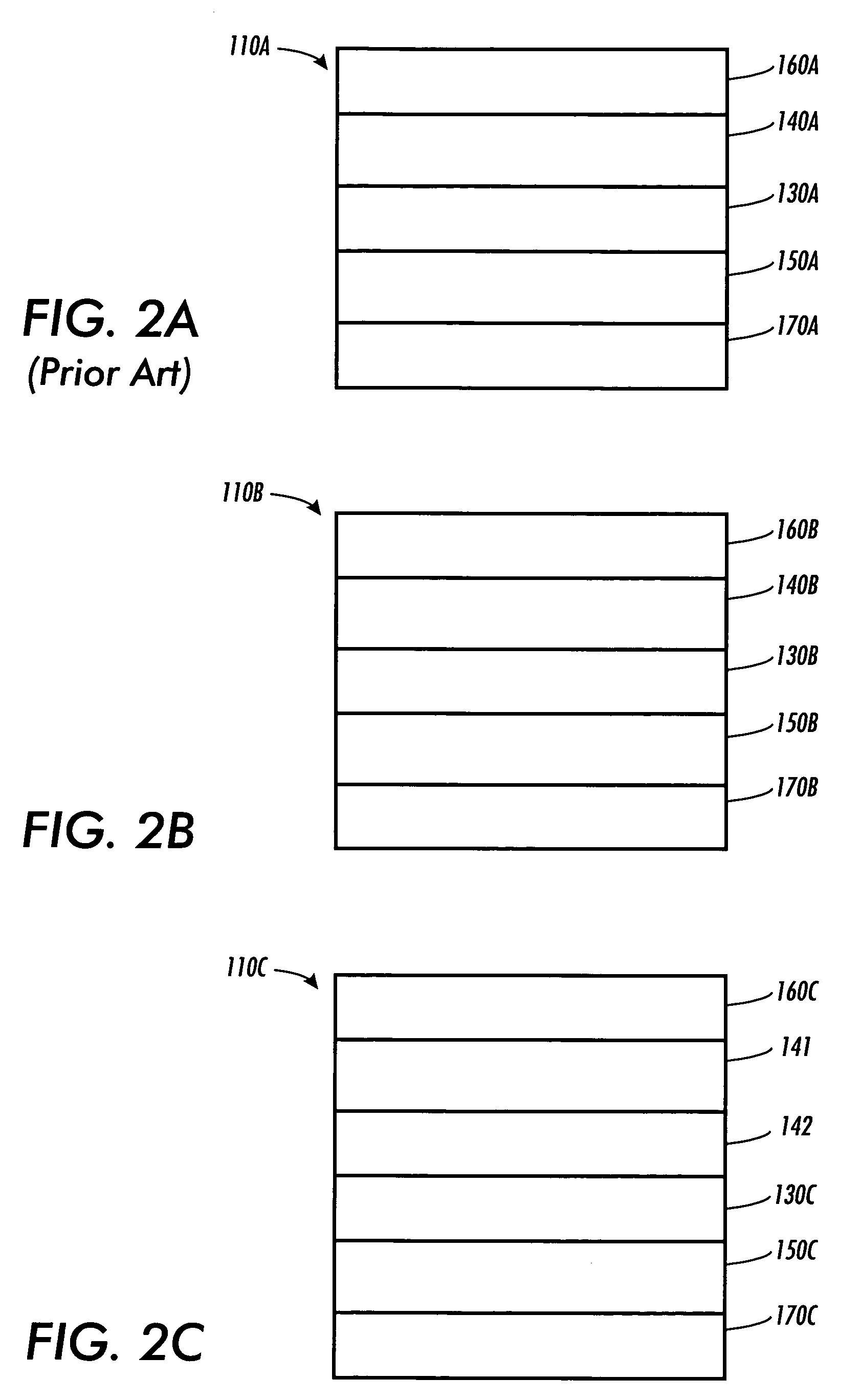

The present invention is an organic light emitting device (OLED) comprising an anode, a cathode and a luminescent region provided between the anode and the cathode. The luminescent region comprises an electron injection and transporting zone and at least one of a hole injection and transporting zone and a mixed charge transport layer. One or both of the electron injection and transporting zone and the mixed charge transporting layer comprises an azole compound represented by formula I and / or II. The provision of the novel azole compounds of the invention as electron transport materials within an organic electroluminescent device advantageously reduces power consumption and increases power conversion efficiency within the device and as such, are suitable for a variety of display applications.

Owner:LG DISPLAY CO LTD

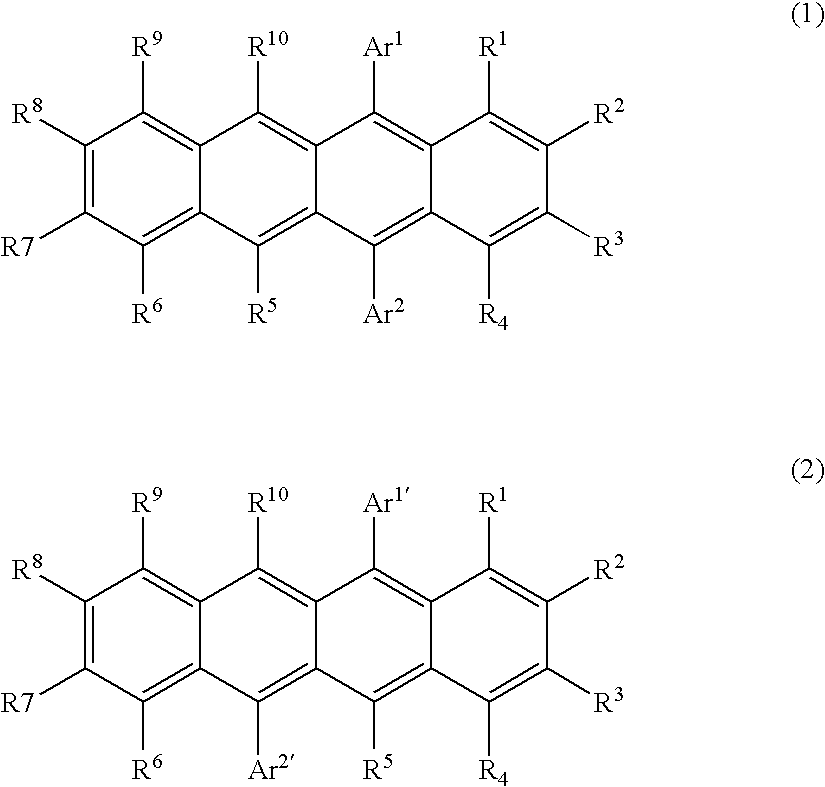

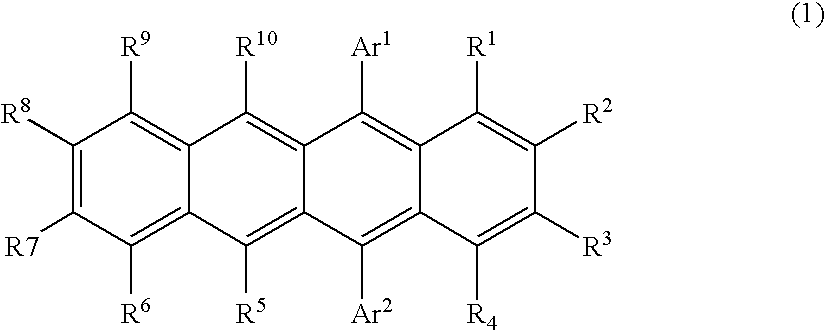

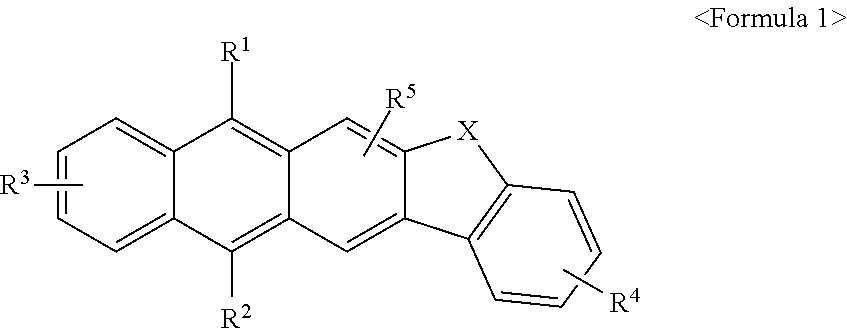

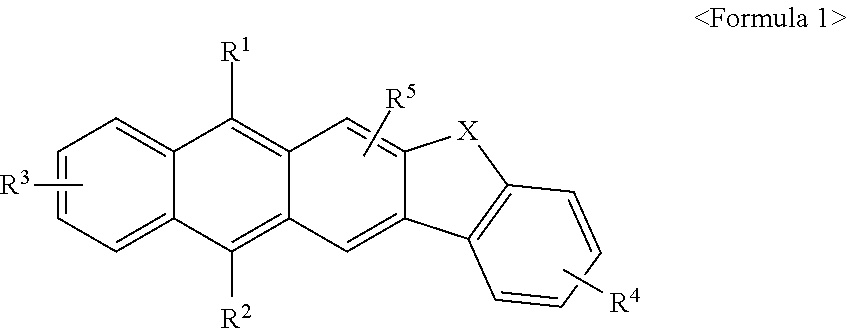

Naphthacene derivative and organic electroluminescent device using the same

InactiveUS20070222373A1Improve efficiencyLong life-timeOrganic chemistryDischarge tube luminescnet screensOrganic layerOrganic electroluminescence

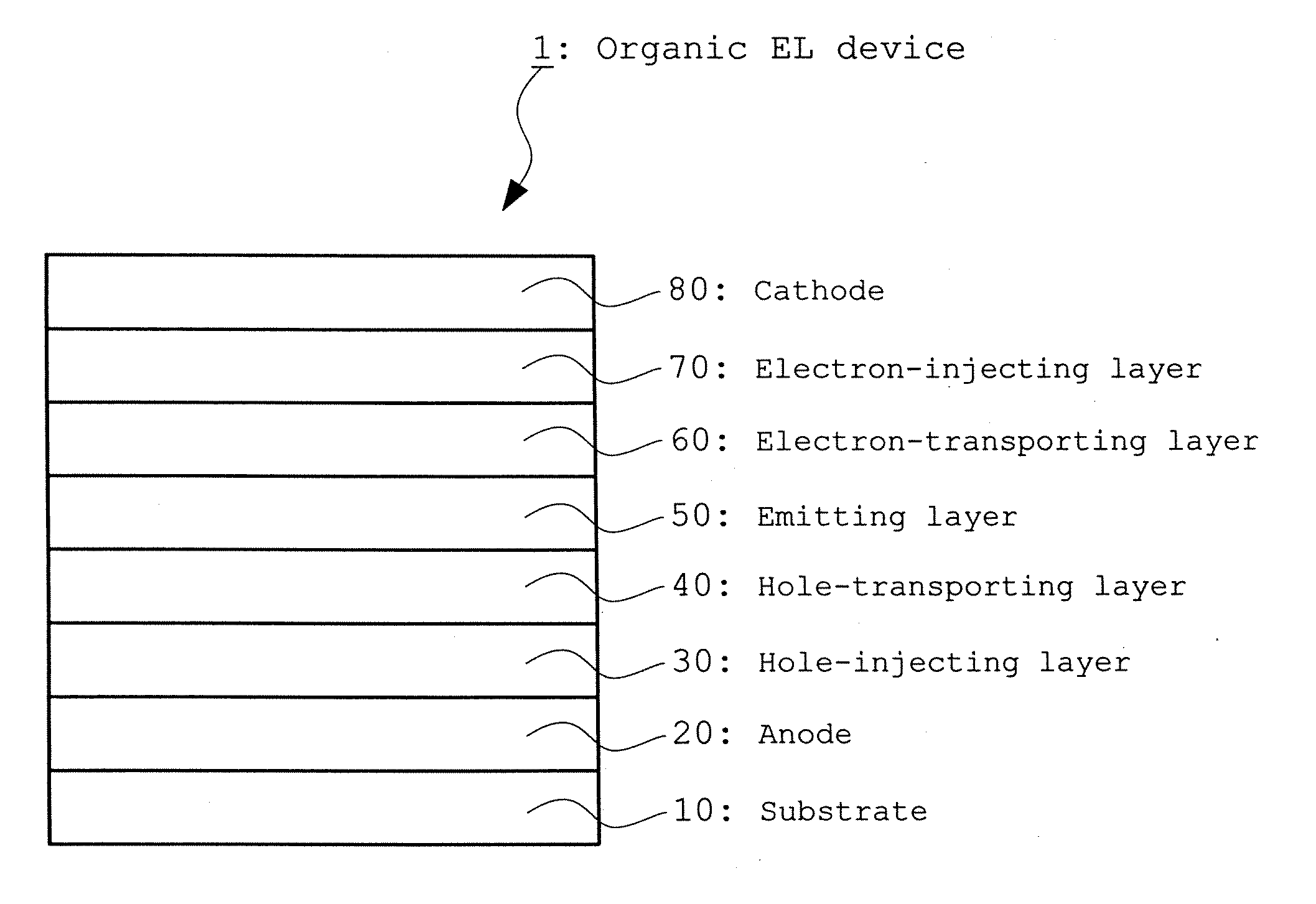

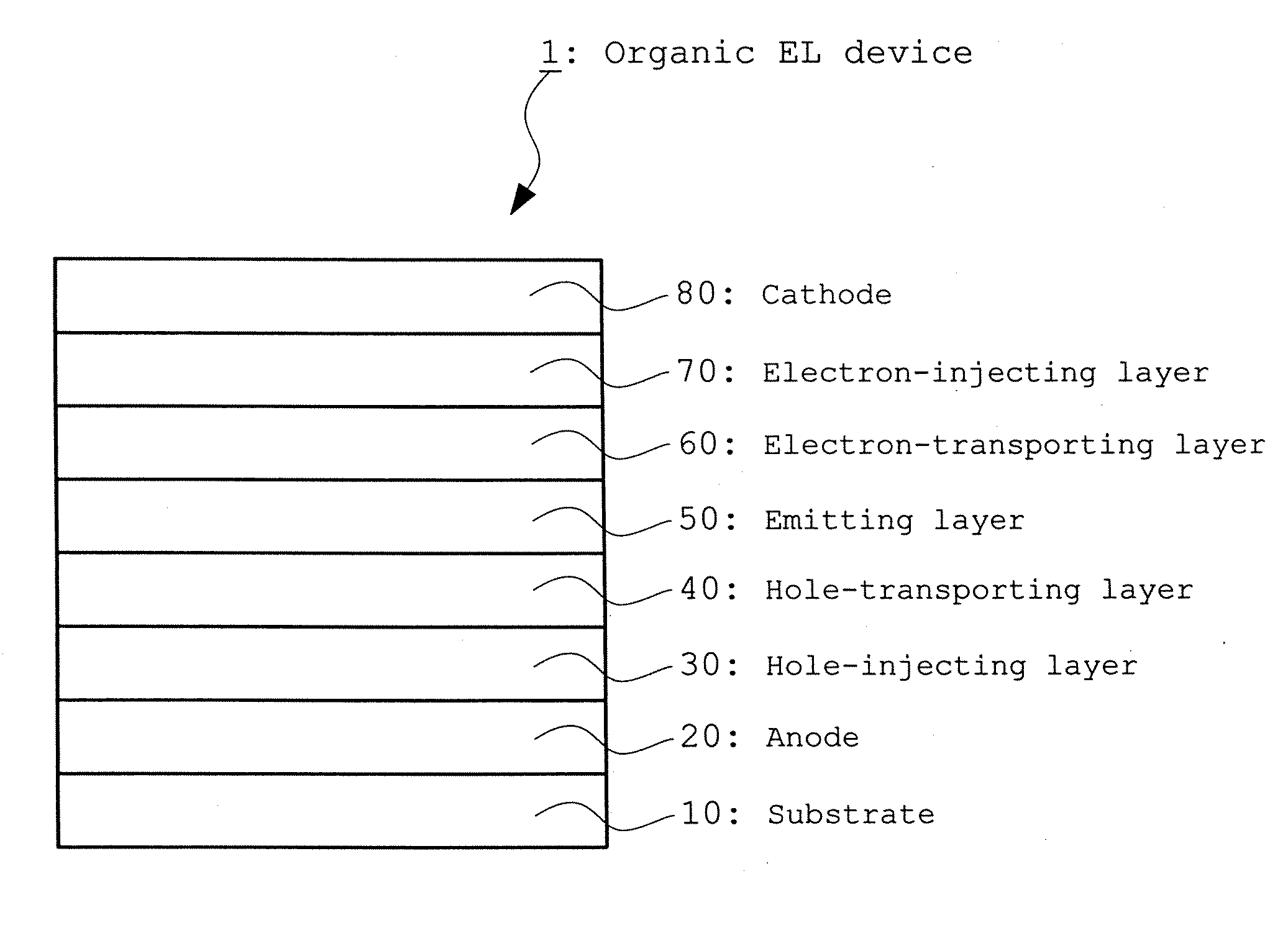

A material for an organic EL device conatining a novel naphthacene derivative; a luminescent material containing a novel naphthacene derivative; and an organic electroluminescent device including one or more organic layers interposed between a cathode and an anode, and at least one layer of the organic layers containing a naphthacene derivative represented by the following formula (1) or (2).

Owner:IDEMITSU KOSAN CO LTD

Organic light emitting devices

ActiveUS7291404B2Improve efficiencyEnhancing lifetimeOrganic chemistryDischarge tube luminescnet screensElectron injectionTransport layer

The present invention is an organic light emitting device (OLED) comprising an anode, a cathode and a luminescent region provided between the anode and the cathode. The luminescent region comprises an electron injection and transporting zone and at least one of a hole injection and transporting zone and a mixed charge transport layer. One or both of the electron injection and transporting zone and the mixed charge transporting layer comprises an azole compound represented by formula I and / or II. The provision of the novel azole compounds of the invention as electron transport materials within an organic electroluminescent device advantageously reduces power consumption and increases power conversion efficiency within the device and as such, are suitable for a variety of display applications.

Owner:LG DISPLAY CO LTD

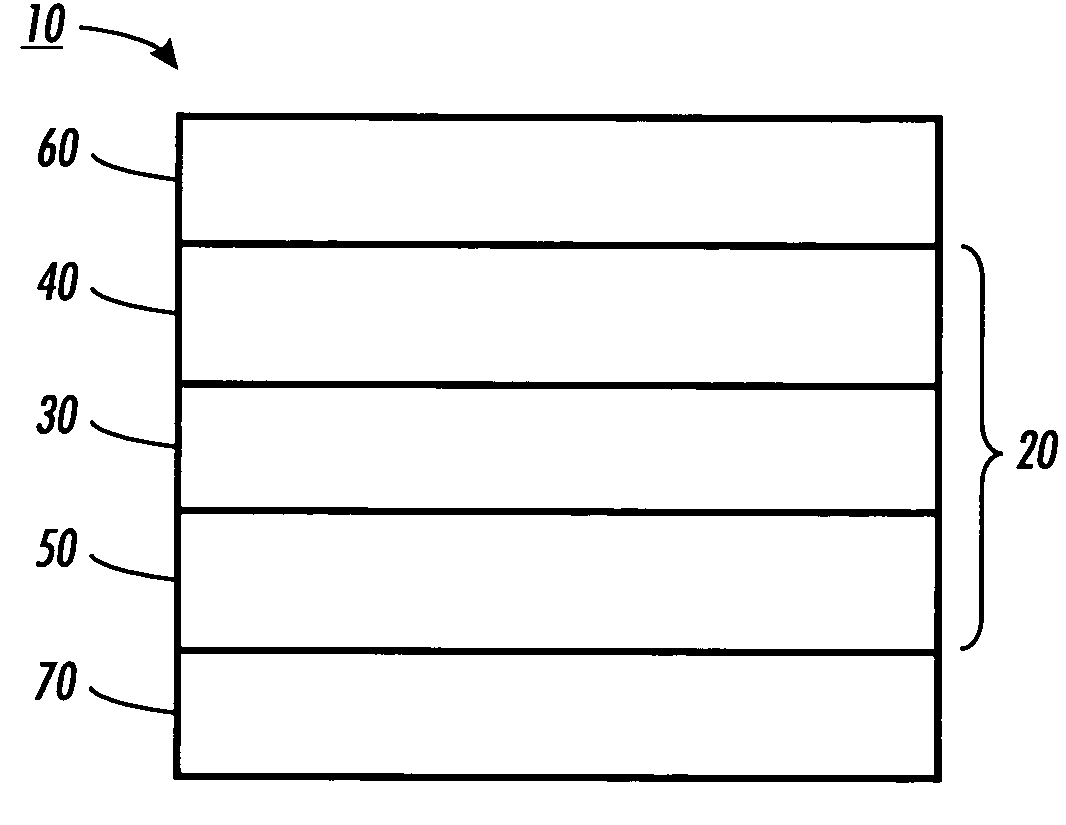

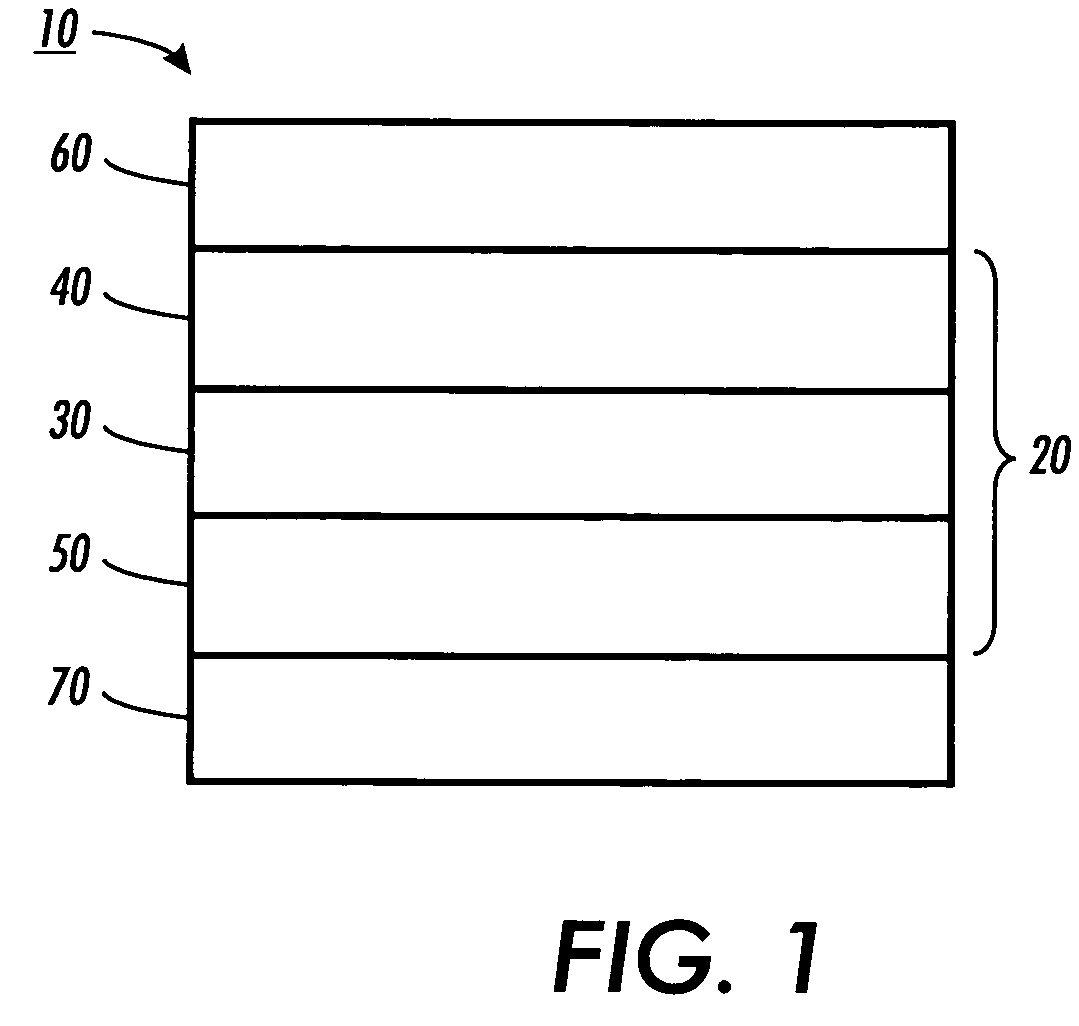

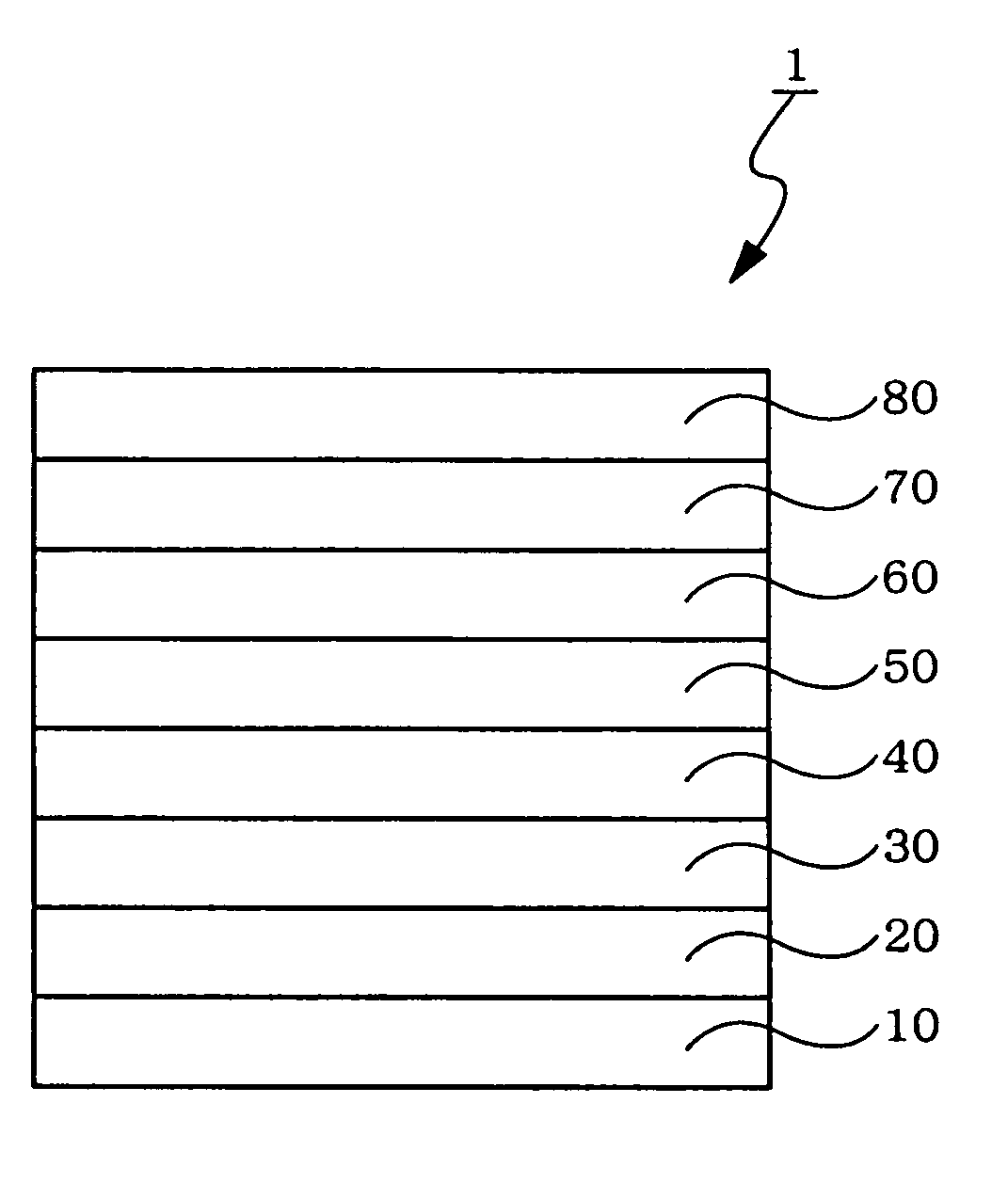

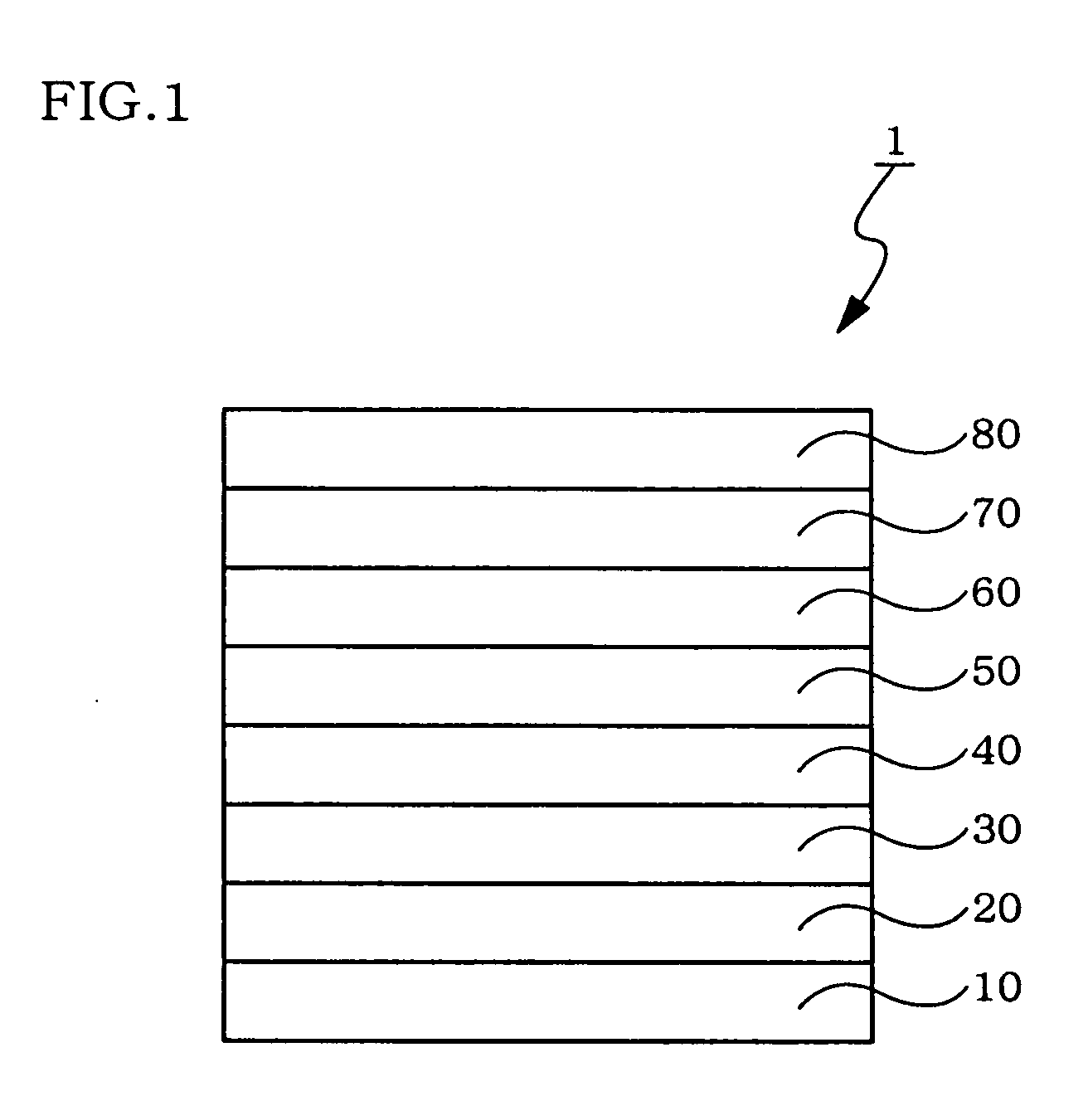

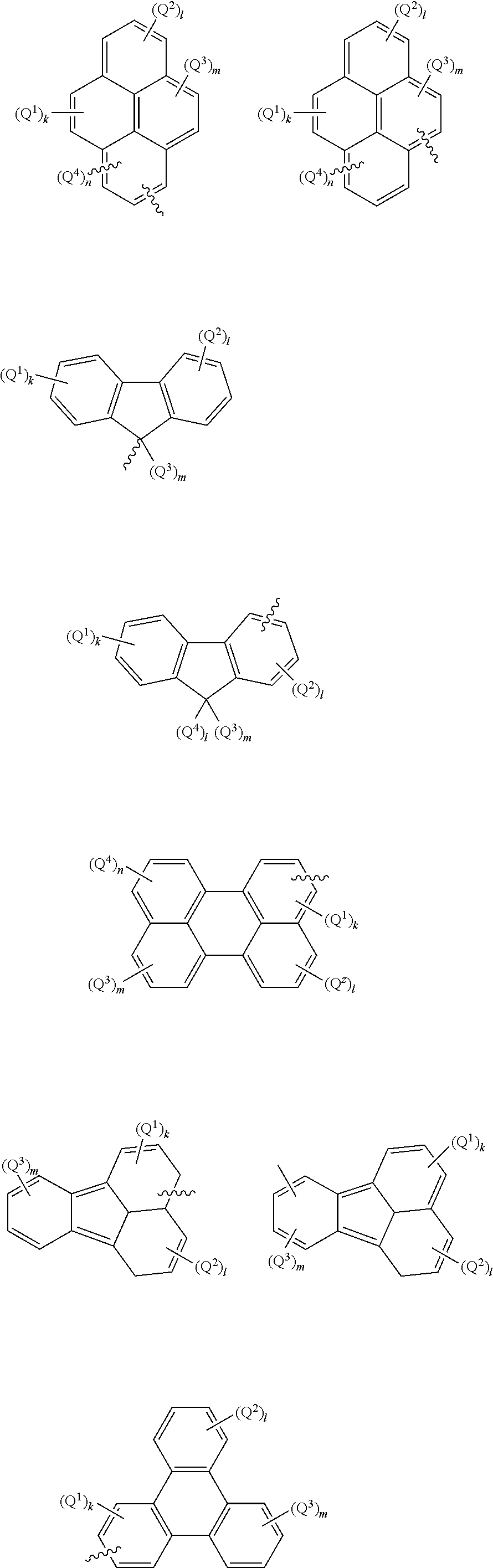

Organic electroluminescent device using fluoranthene derivative and indenoperylene derivative

InactiveUS20080007160A1Improve efficiencyEnhancing lifetimeDischarge tube luminescnet screensElectroluminescent light sourcesHydrogen atomHost material

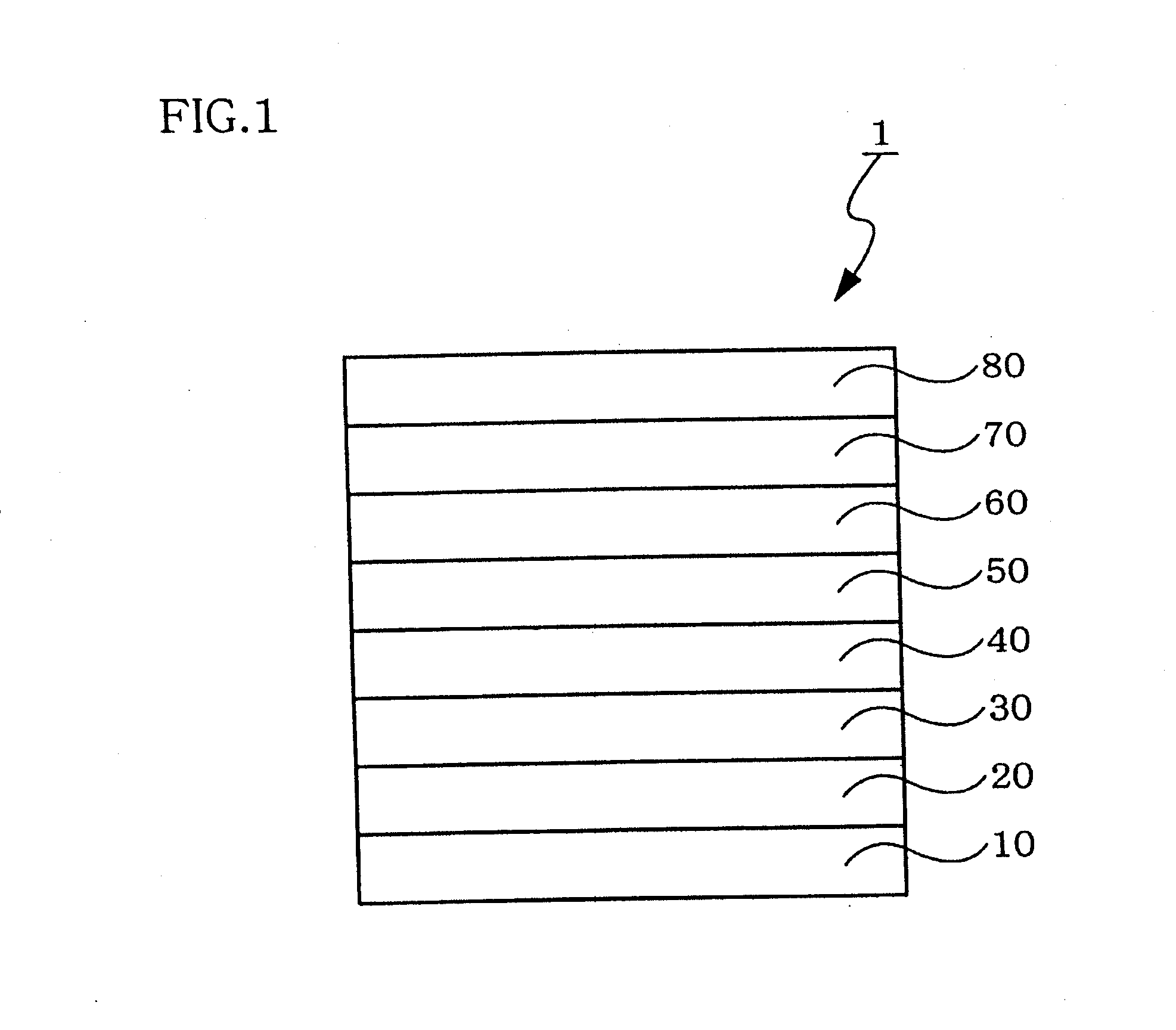

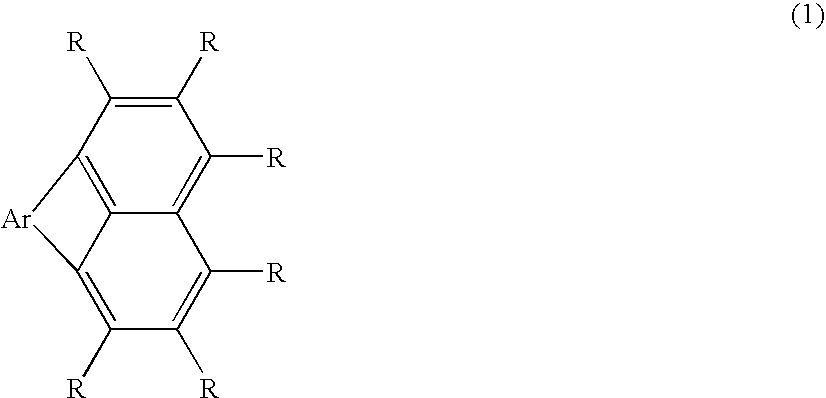

An organic electroluminescent device including an anode (20), a cathode (80), and at least an emitting layer (50) and an electron-transporting layer (60) provided between the anode (20) and the cathode (80); the emitting layer (50) containing a host material which is a fluoranthene derivative represented by the following formula (1) and a dopant material which is an indenoperylene derivative: wherein Ar is a substituted or unsubstituted aromatic group having 6 to 50 nucleus carbon atoms; and Rs are independently a hydrogen atom, substituted or unsubstituted aromatic group having 6 to 50 nucleus carbon atoms, or substituted or unsubstituted alkyl group having 1 to 50 carbon atoms.

Owner:IDEMITSU KOSAN CO LTD

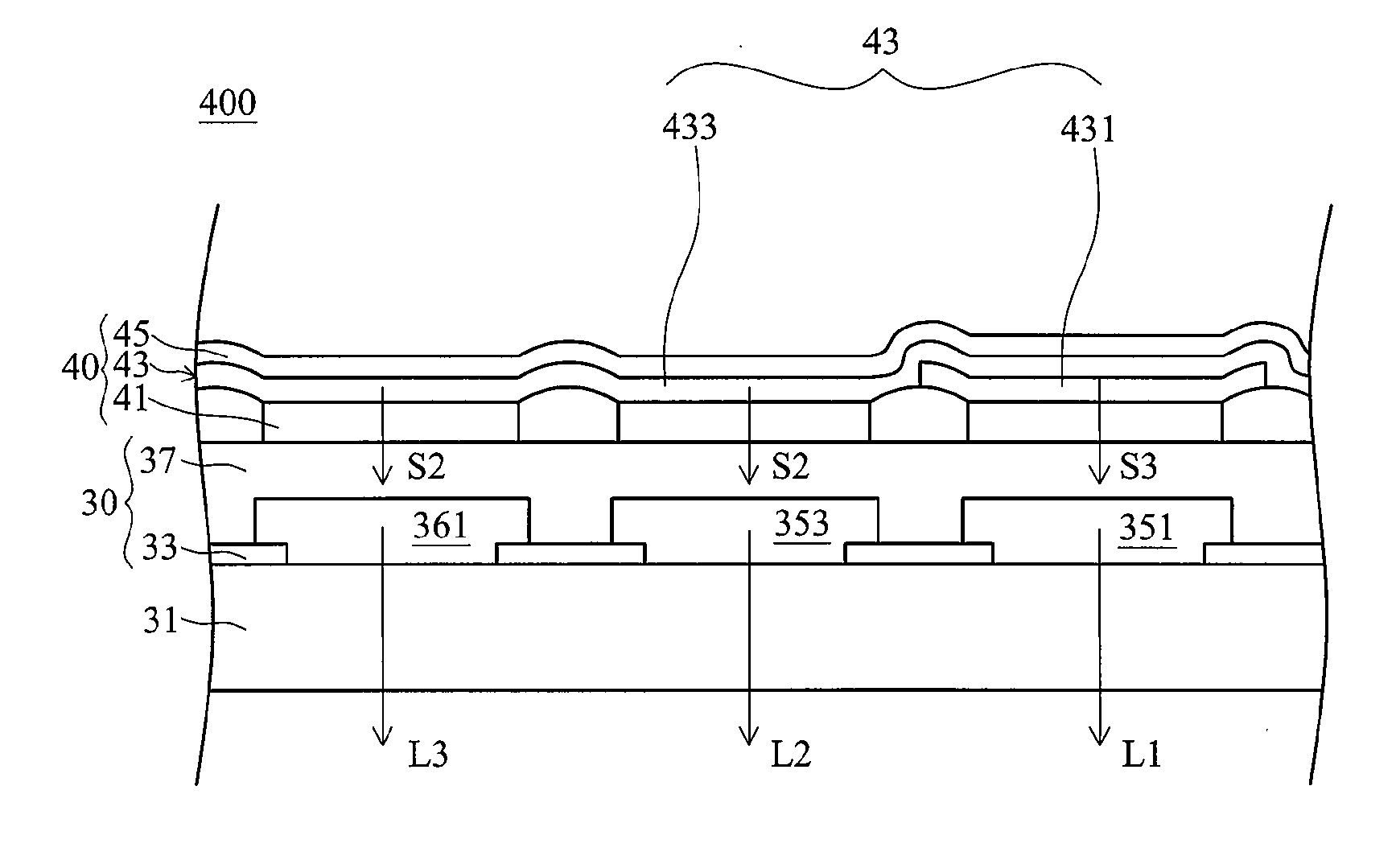

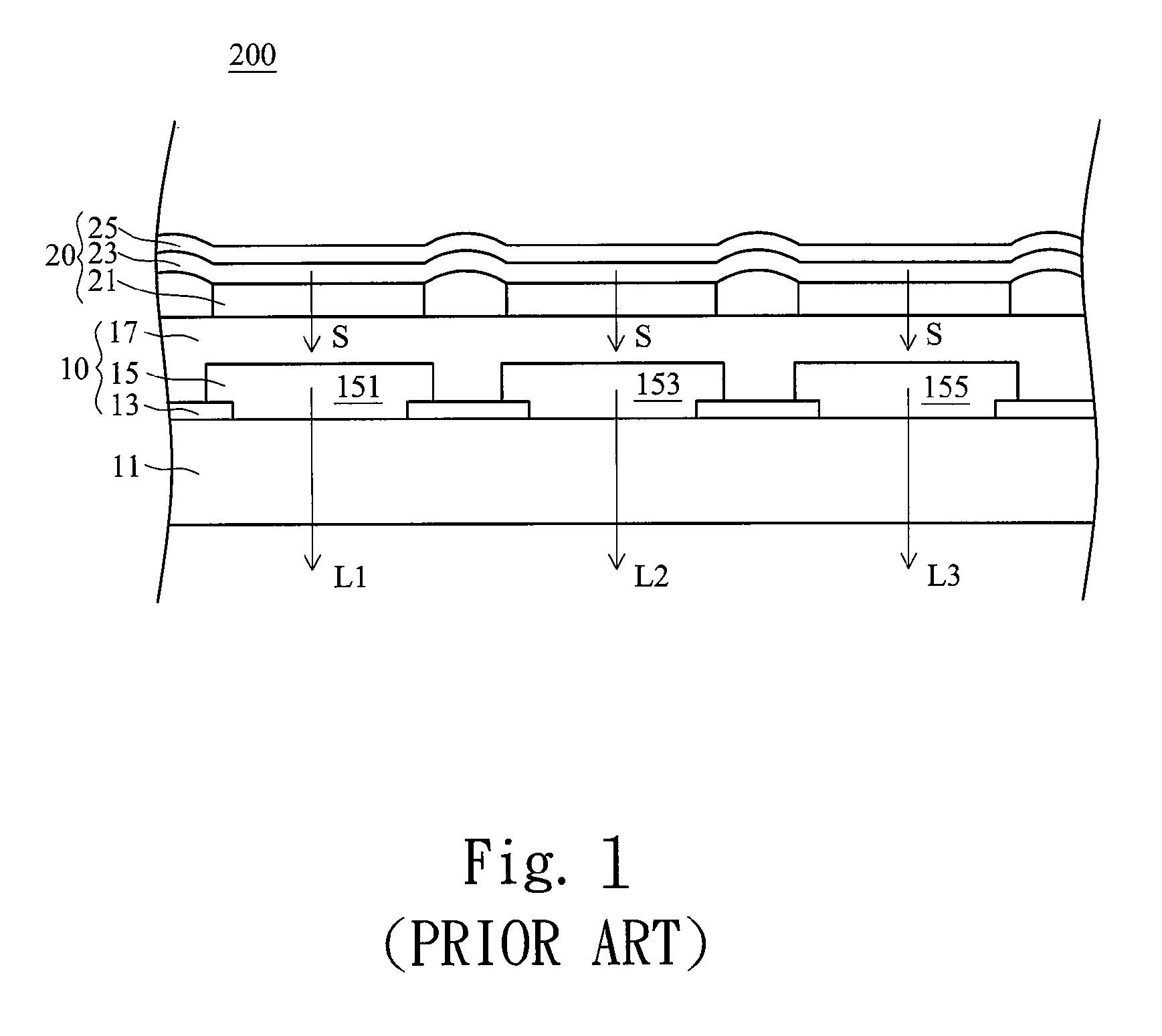

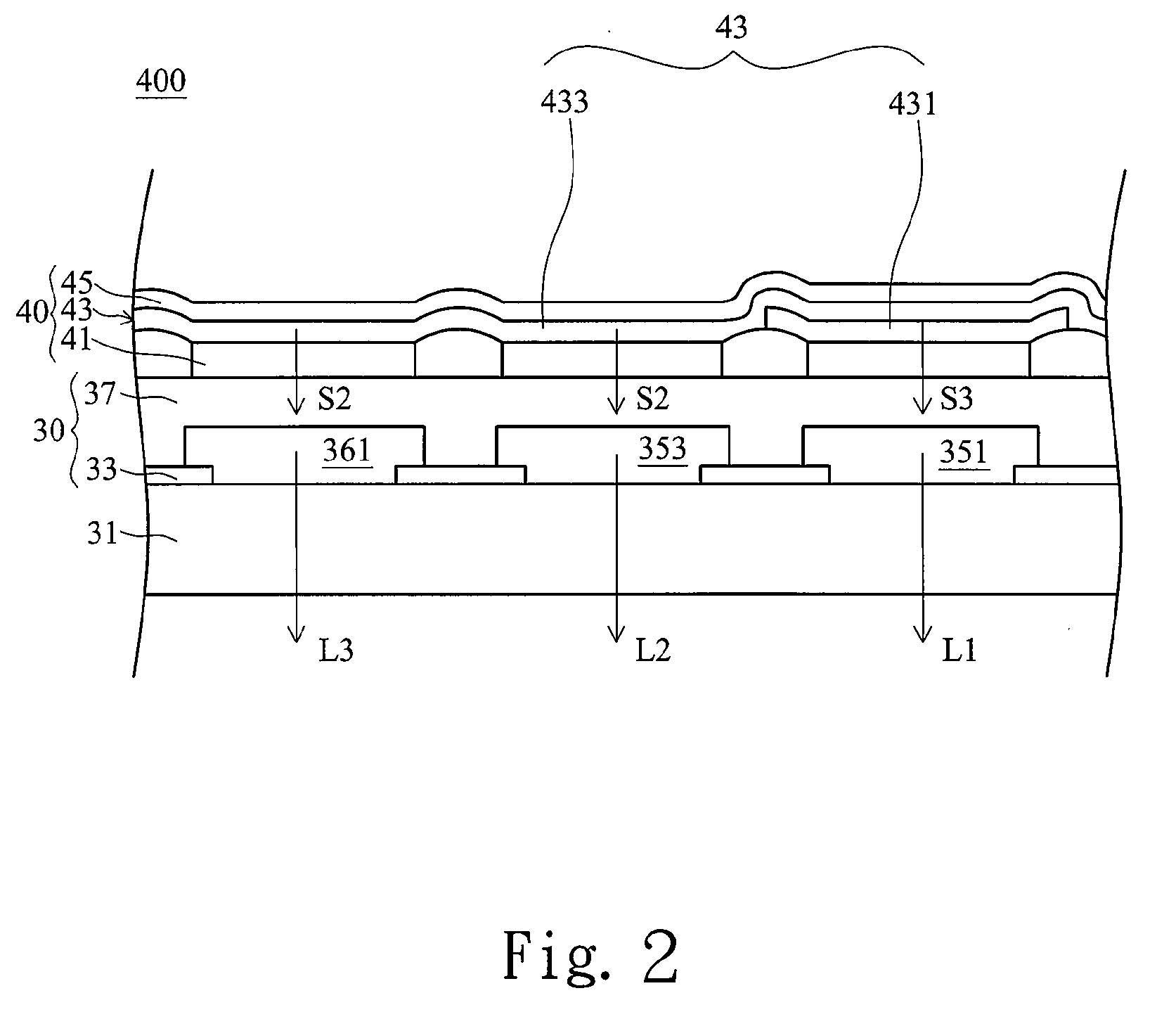

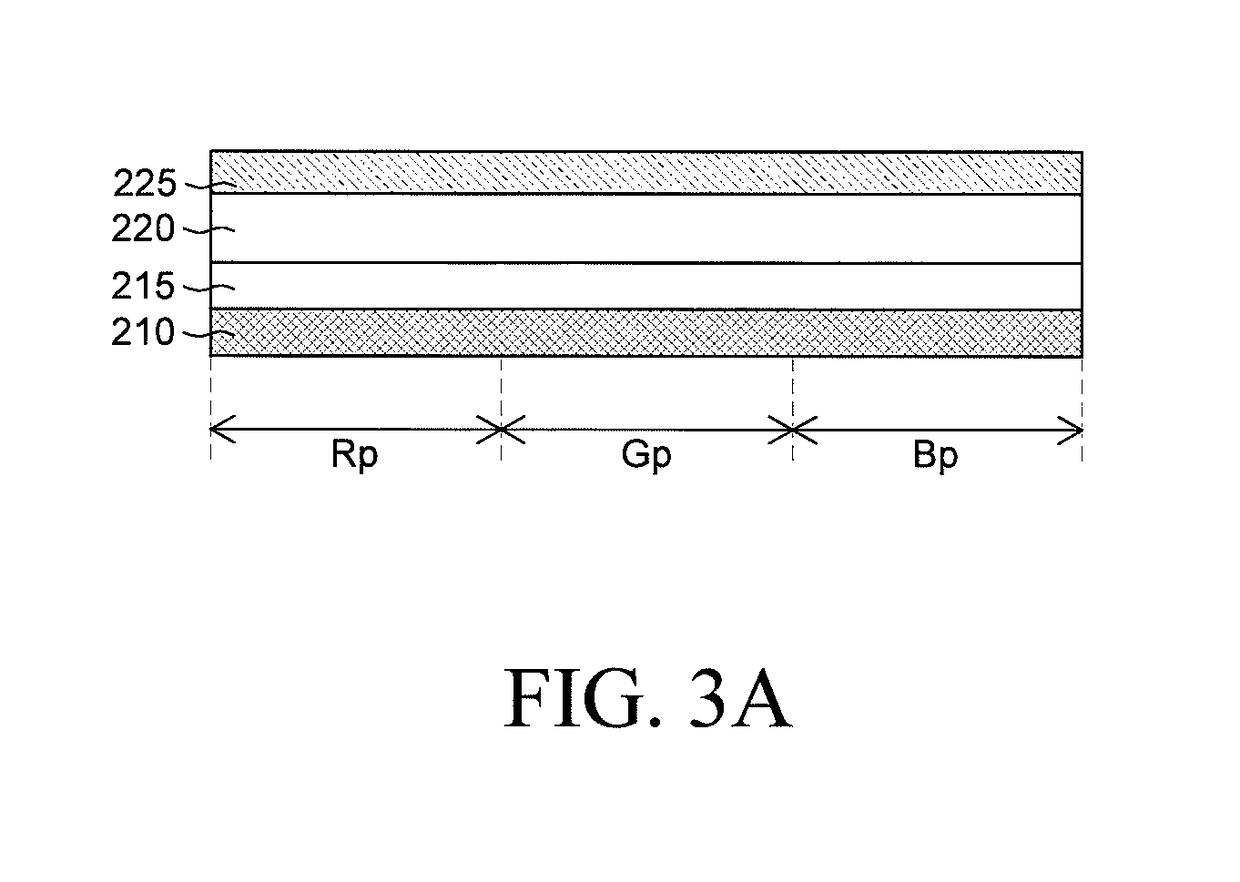

Color Filter Conversion Apparatus and an Organic Electroluminescent Display Apparatus Thereof

InactiveUS20070024186A1Increase ratingsImprove transmittanceDischarge tube luminescnet screensOptical filtersResistTransmittance

The present invention relates to a color filter conversion apparatus. More particularly, the present invention relates to a color filter conversion apparatus and the application thereof. A color conversion layer, a first photo resist, and a second photo resist are arranged on the substrate. In addition, a first organic light emitting element is arranged on the vertically extended region of the second photo resist and a second organic light emitting element is arranged on the vertically extended region of the first photo resist, the second photo resist and the color conversion layer. Thus, the times for evaporating processes are decreased. Furthermore, the transmittance through the photo resist for the light source produced by the organic light emitting element is raised and the converting efficiency of the color conversion layer can also be enhanced.

Owner:UNIVISION TECHNOLOGY

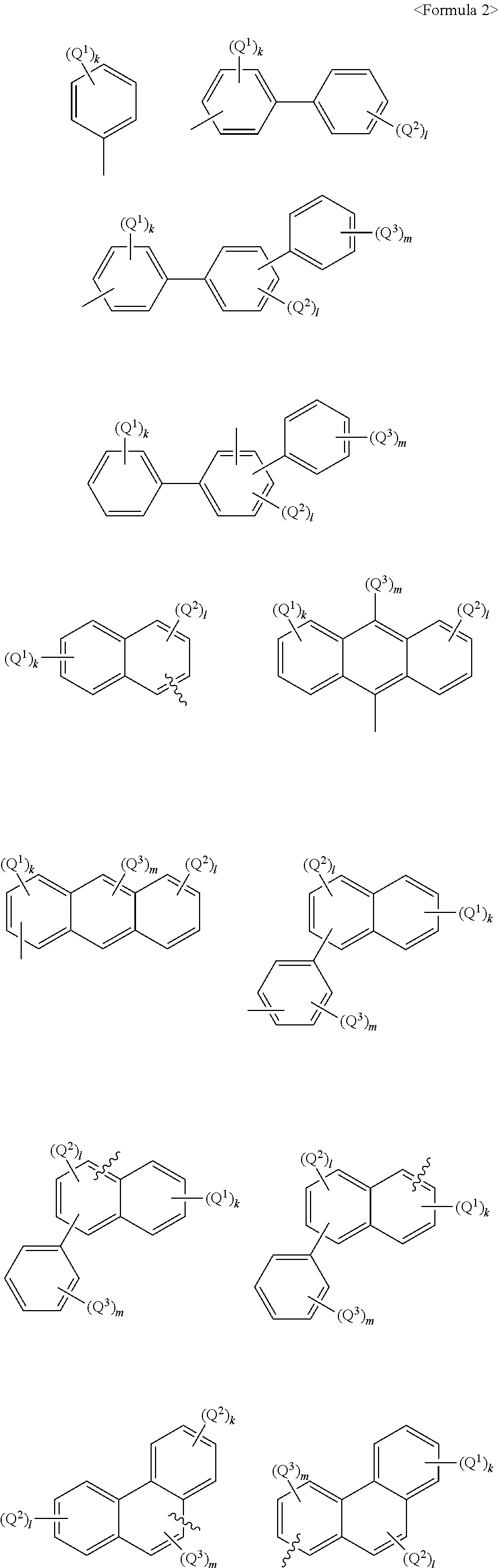

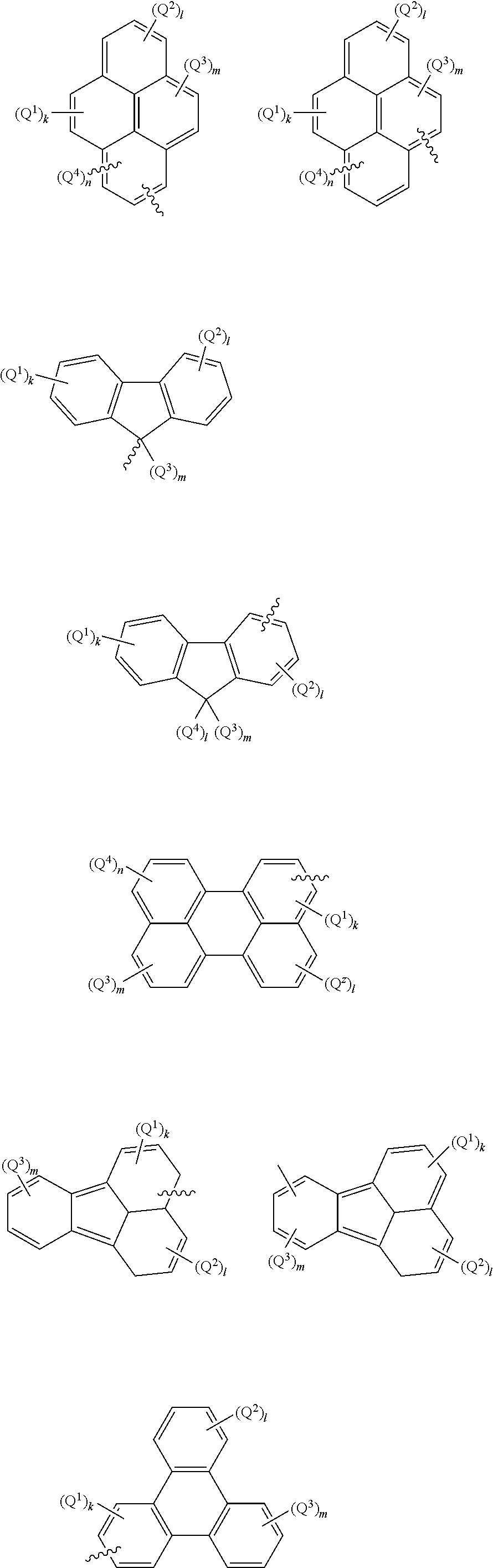

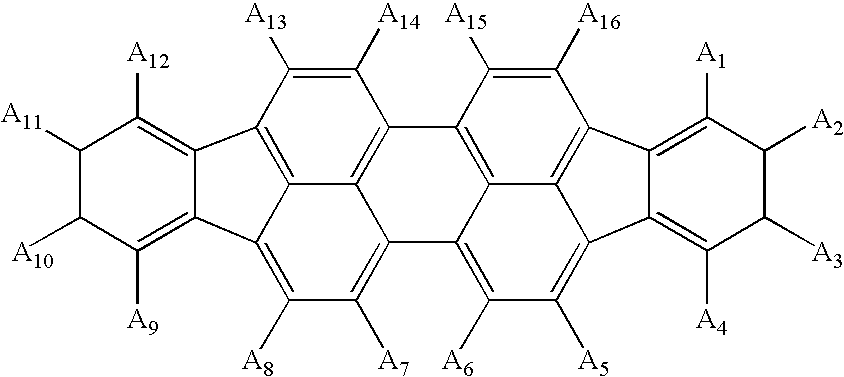

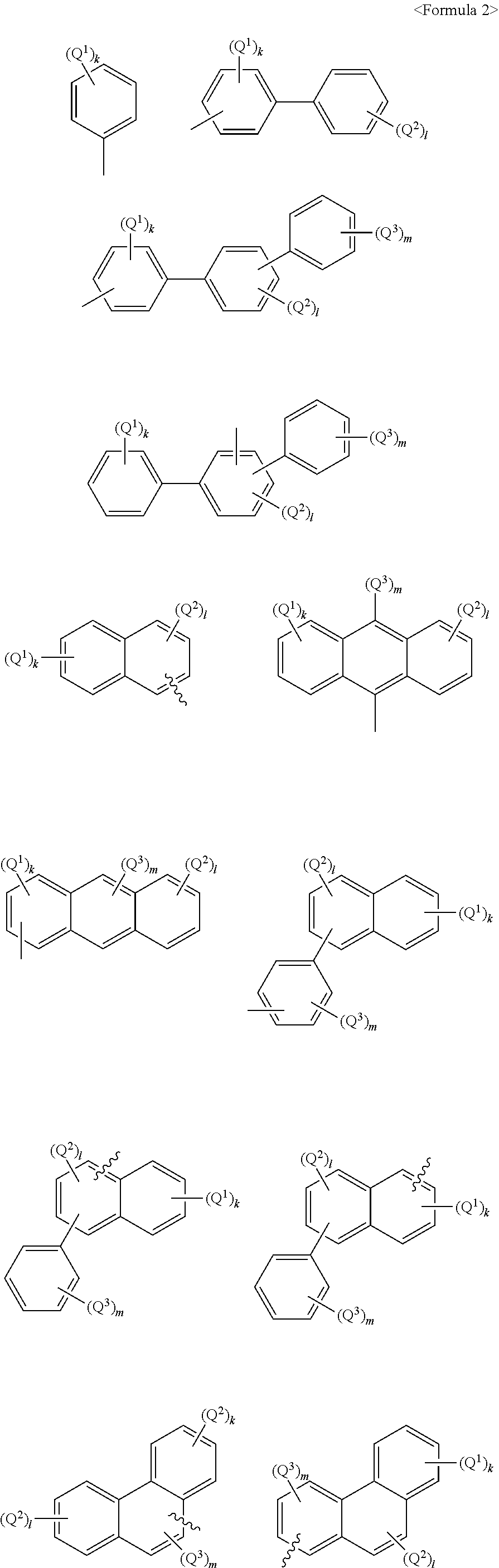

Anthracene derivatives and organic electroluminescent device using same

ActiveUS20110057182A1High color purityImprove efficiencyGroup 4/14 element organic compoundsOrganic compound preparationAnthraceneAryl

Provided are a novel anthracene derivative and an organic light-emitting device using the same, and more particularly, an anthracene derivative having a core (e.g., an indenoanthracene core) where an anthracene moiety with excellent device characteristics is fused with a fluorene moiety or the like with excellent fluorescent properties, wherein an aryl group is introduced at the core, and an organic light-emitting device using the anthracene derivative, which is enhanced in efficiency, operating voltage, lifetime, etc.

Owner:SOLUS ADVANCED MATERIALS CO LTD

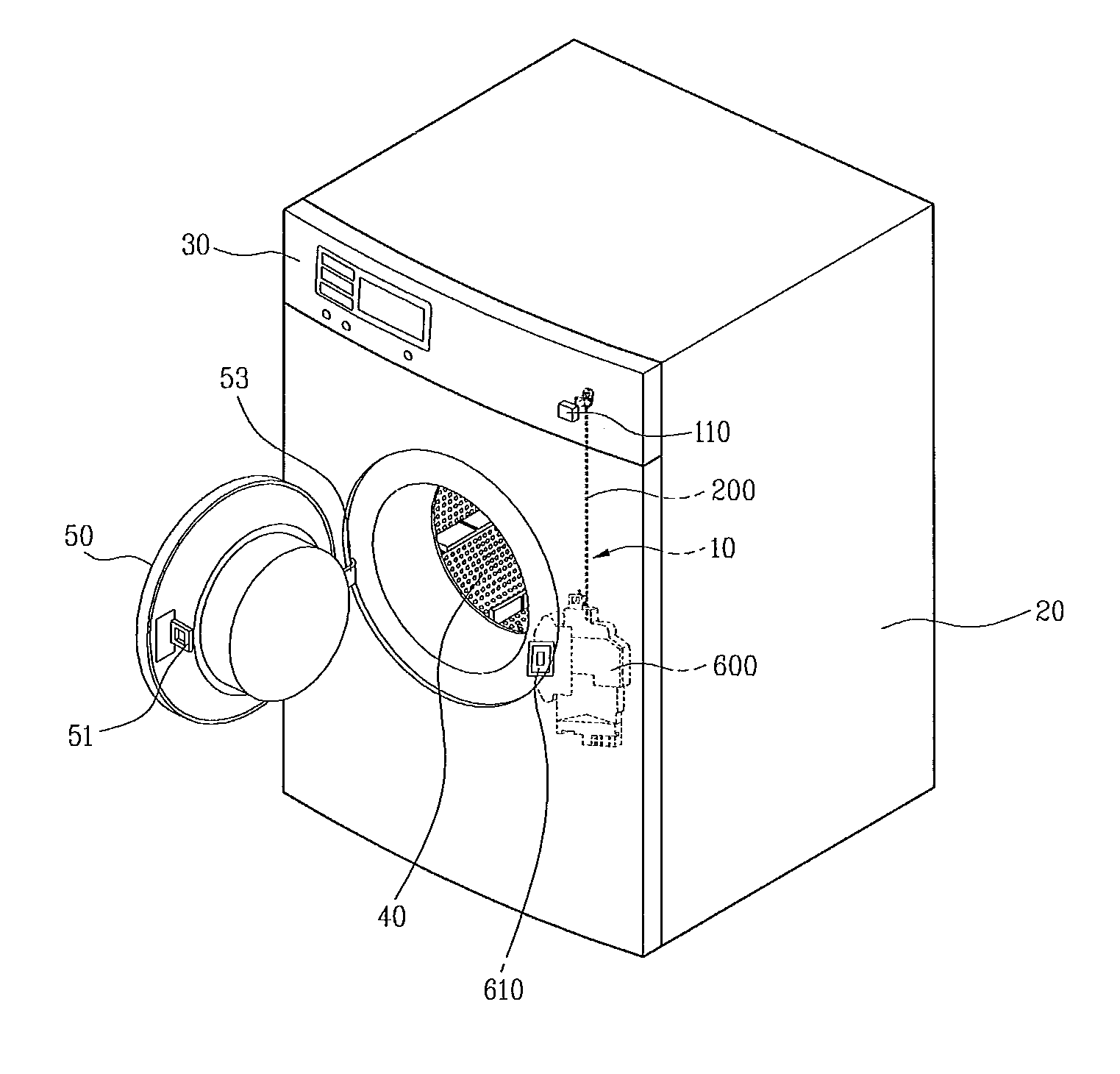

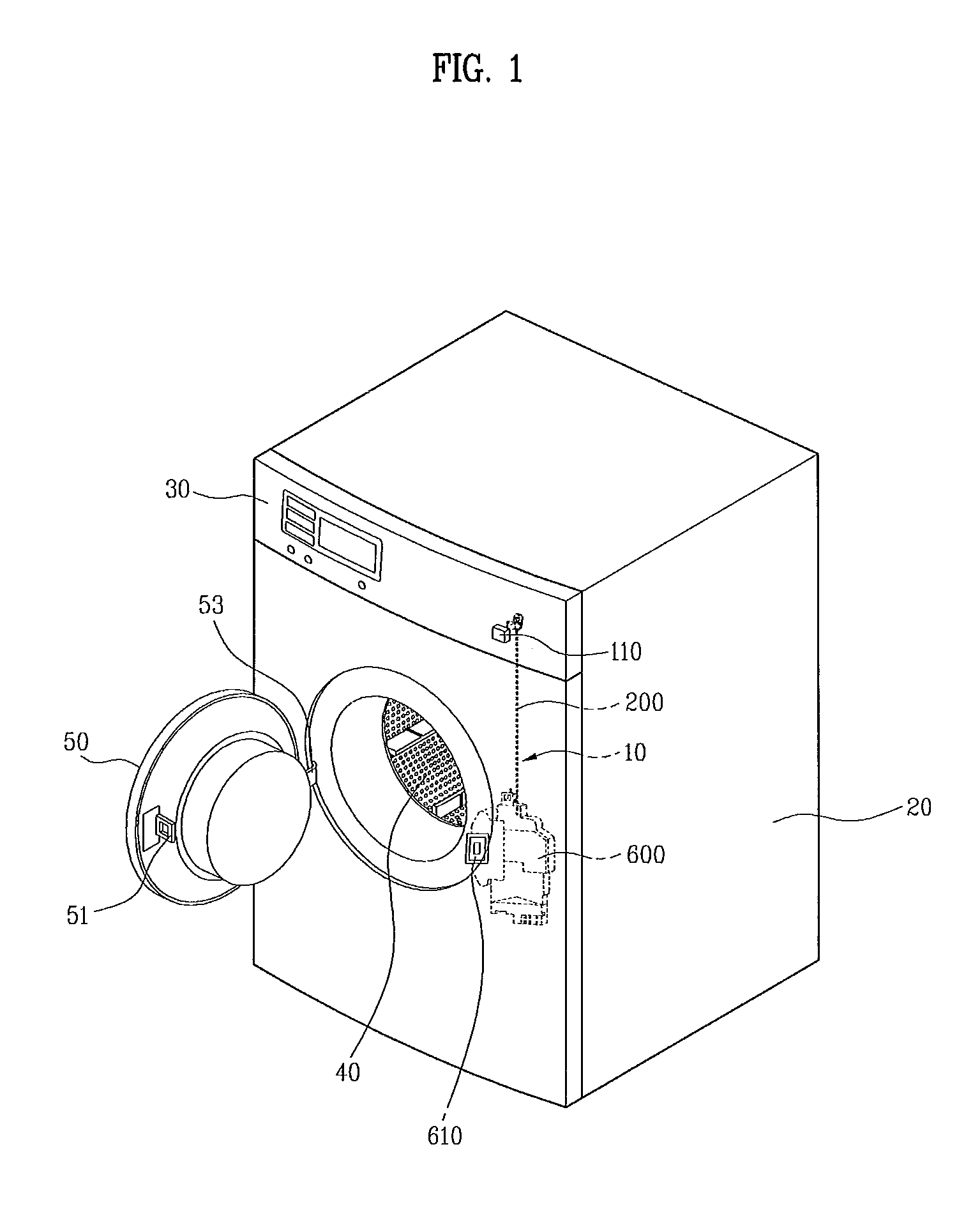

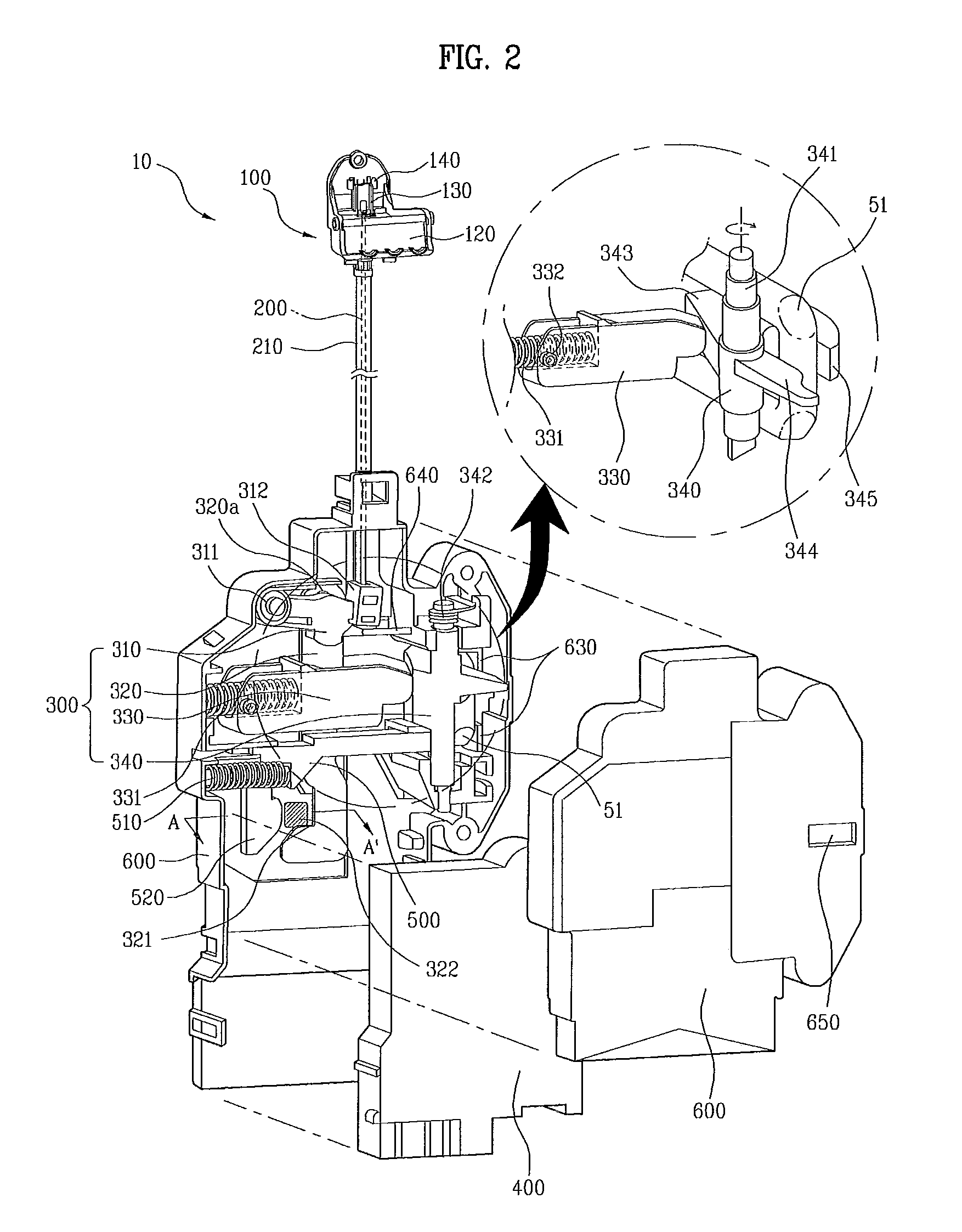

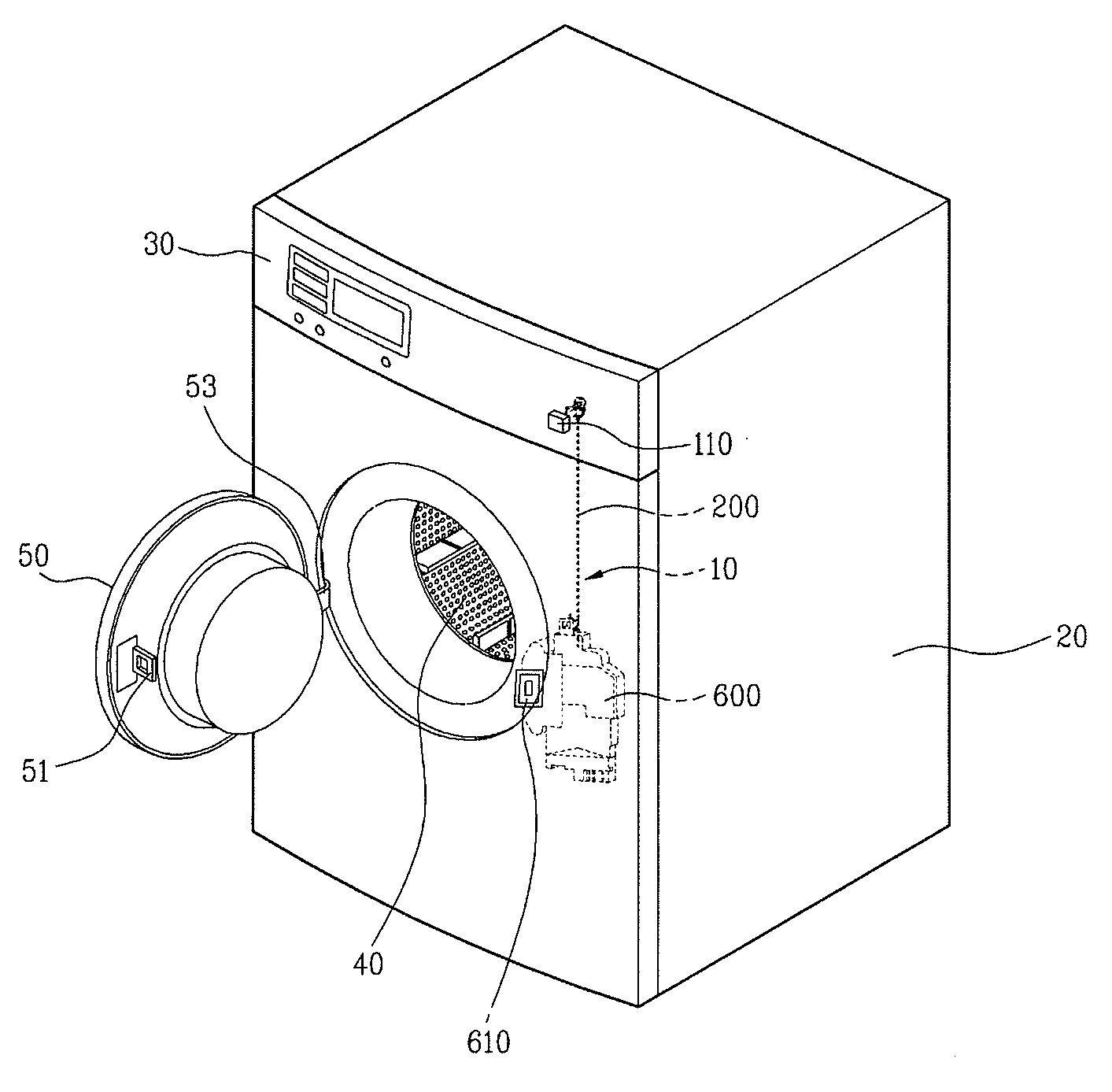

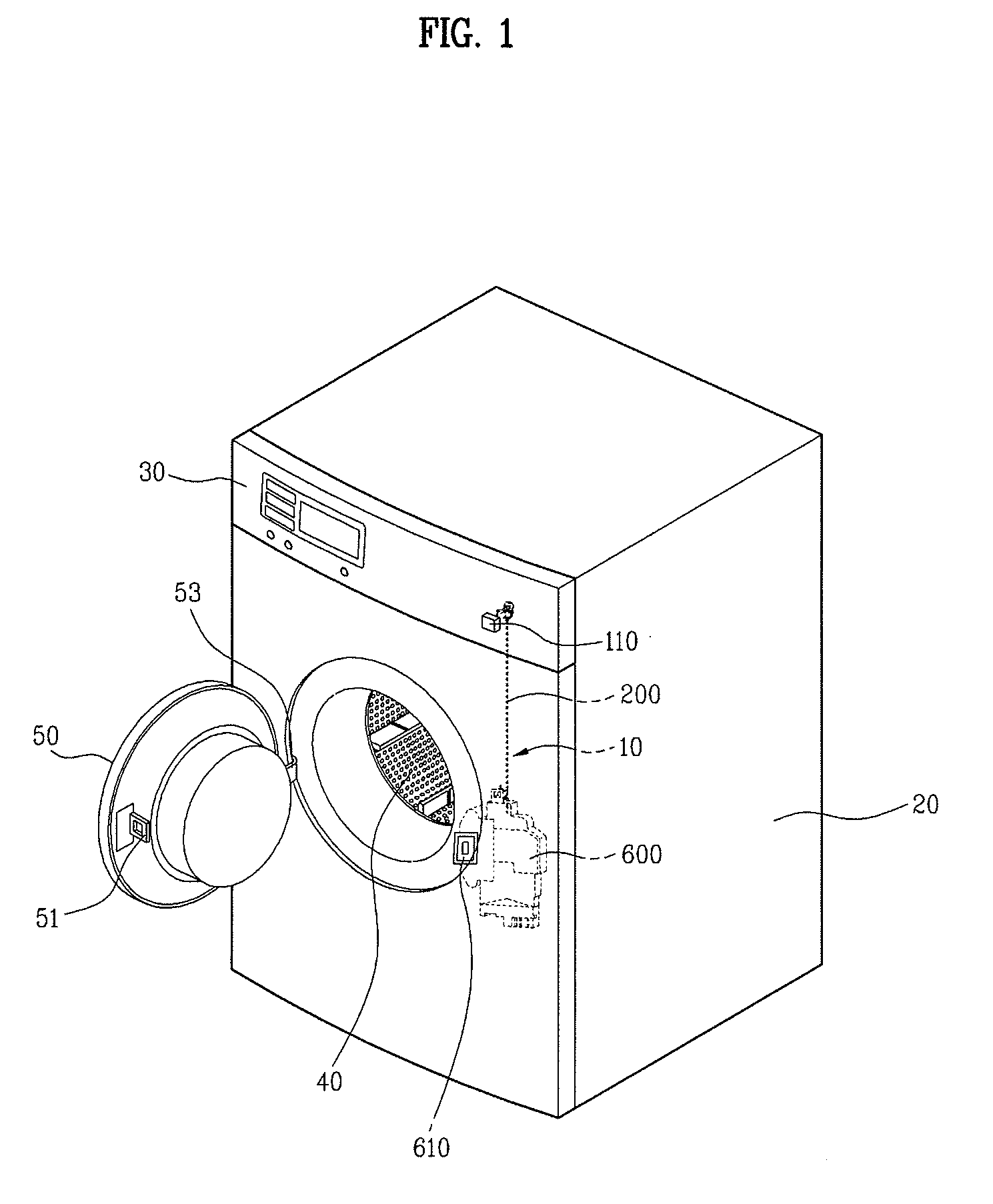

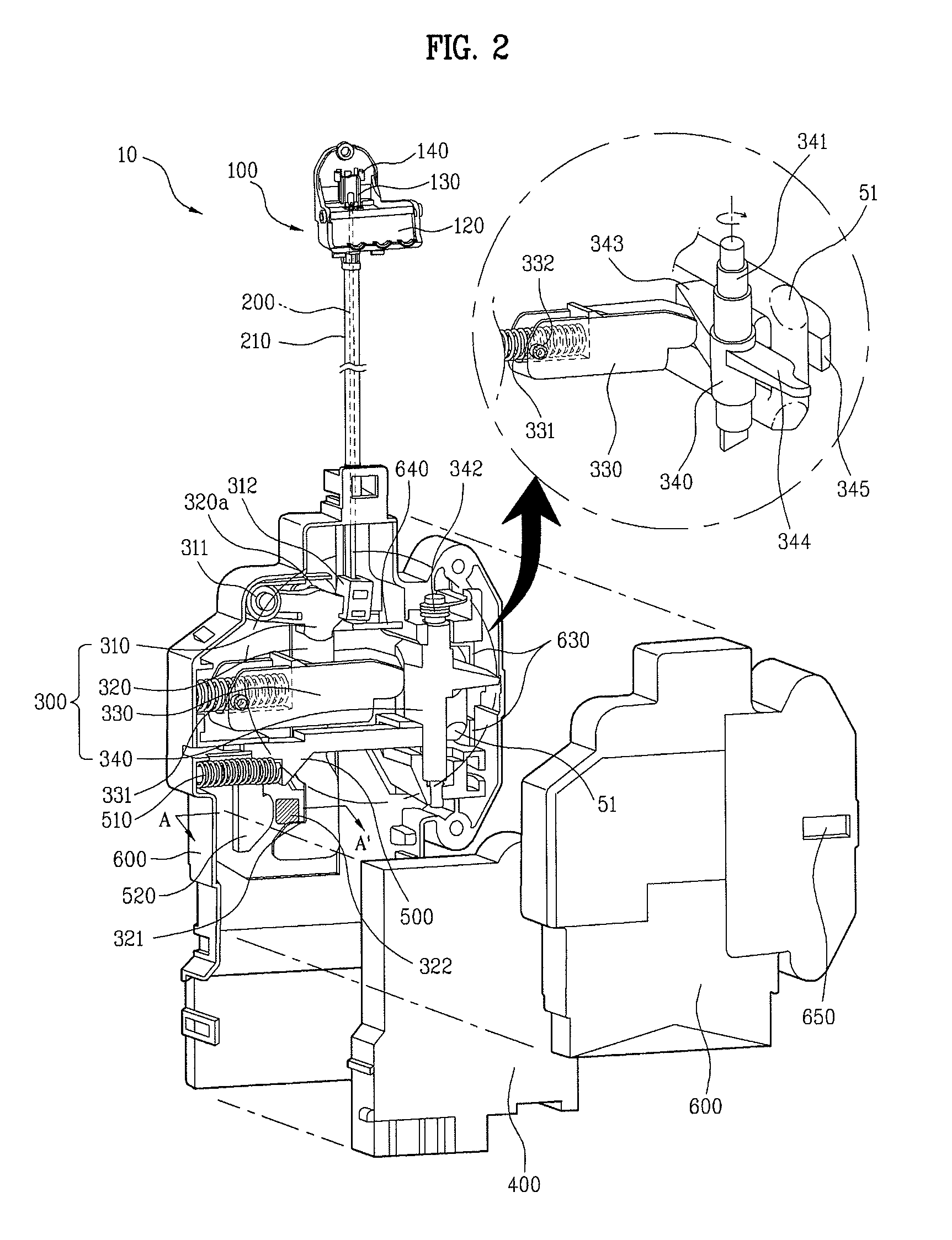

Laundry machine

The present invention relates to laundry machines, and, more particularly, to a safe laundry machine which enables a user to open / close a door easily, and can prevent an accident caused by opening / closing of the door from taking place.The laundry machine includes a cabinet, a drum rotatably mounted in the cabinet, a door having a latch for being opened / closed selectively to expose an inside of the drum to an outside of the laundry machine, and a door switch assembly provided for enabling opening / closing of the door, wherein the door switch assembly includes a switch unit for making selective connection to the latch, and an opening operation unit spaced from the switch unit for the user to enable to disconnect the connection between the latch and the switch unit.

Owner:LG ELECTRONICS INC

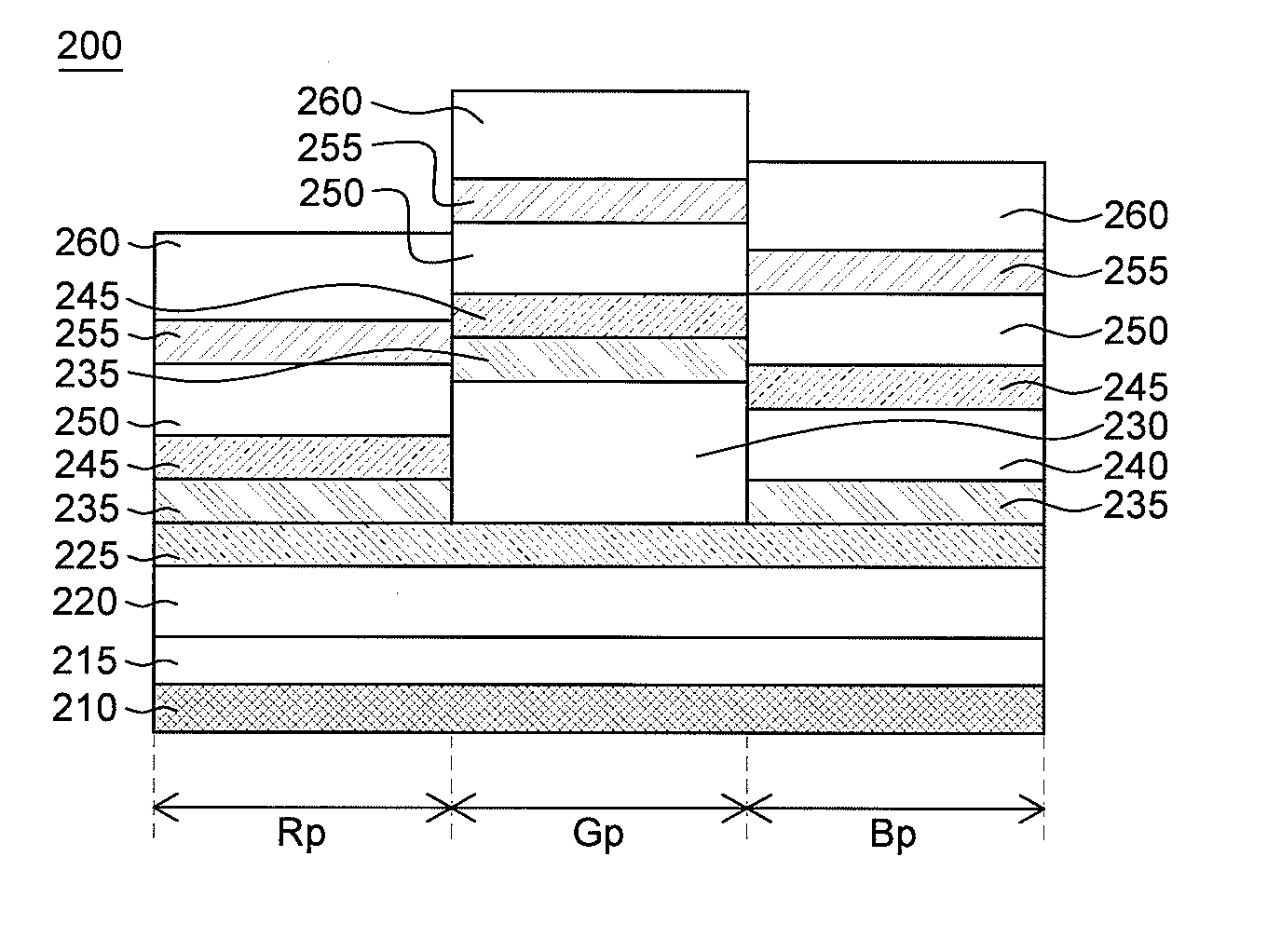

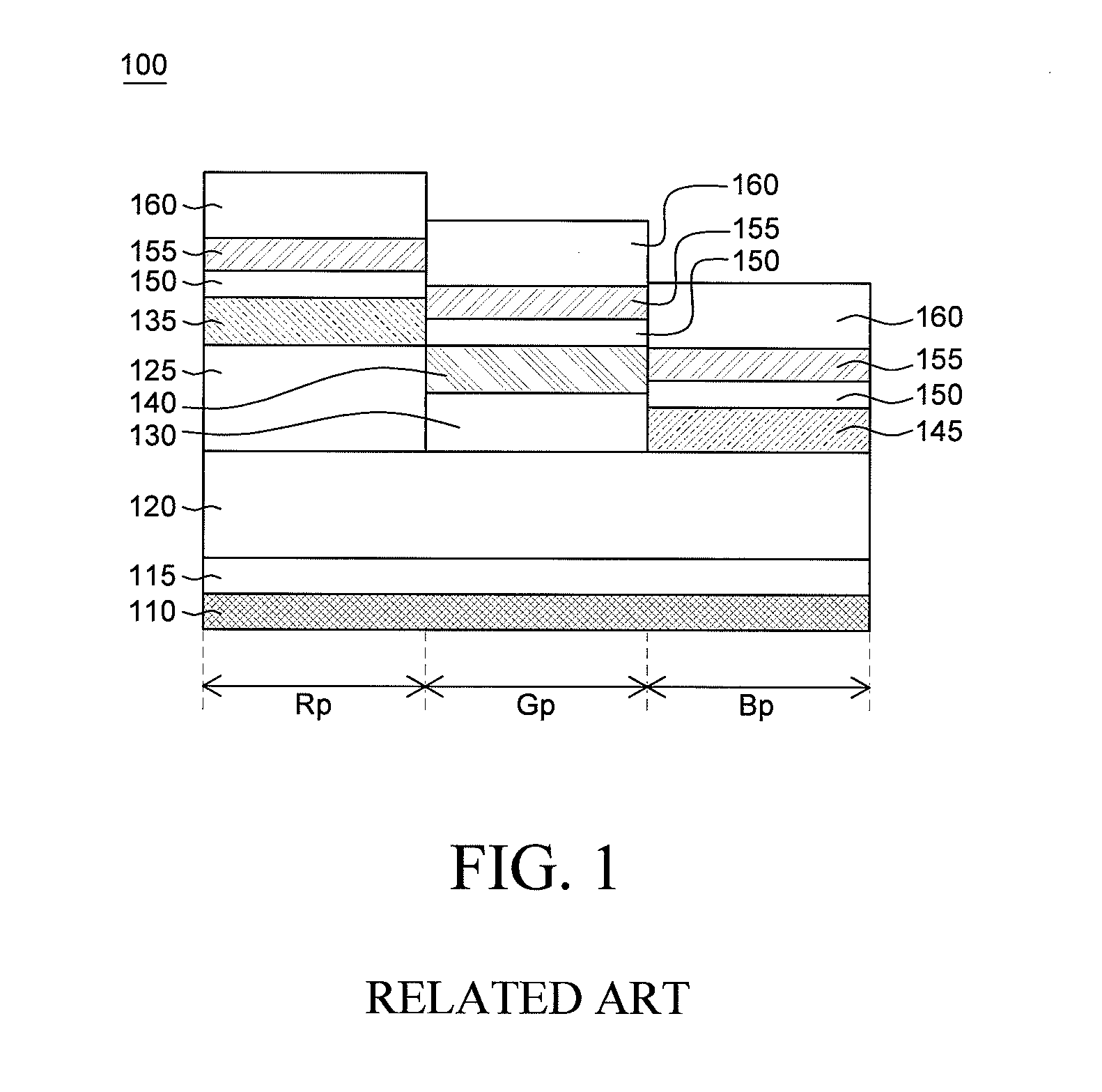

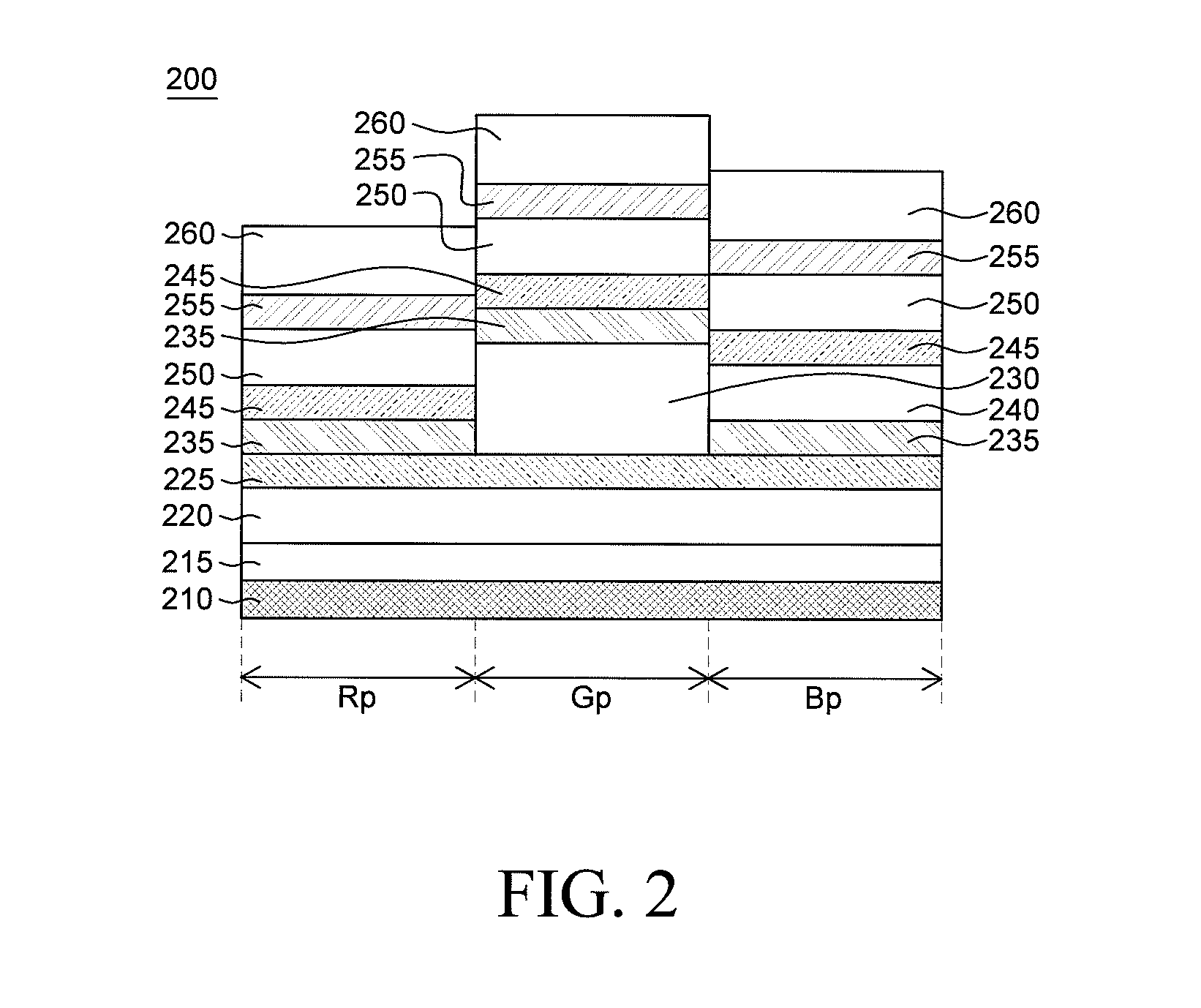

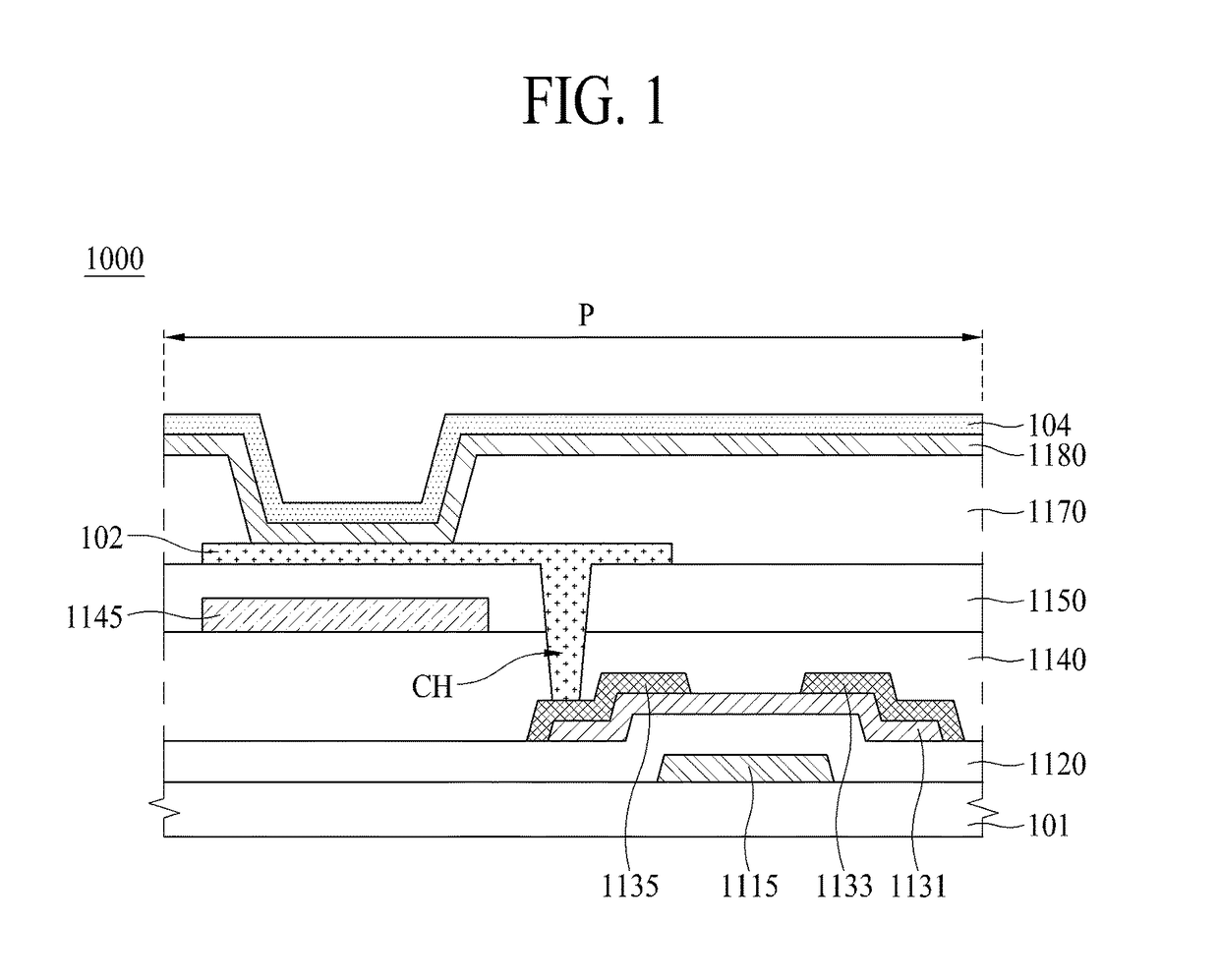

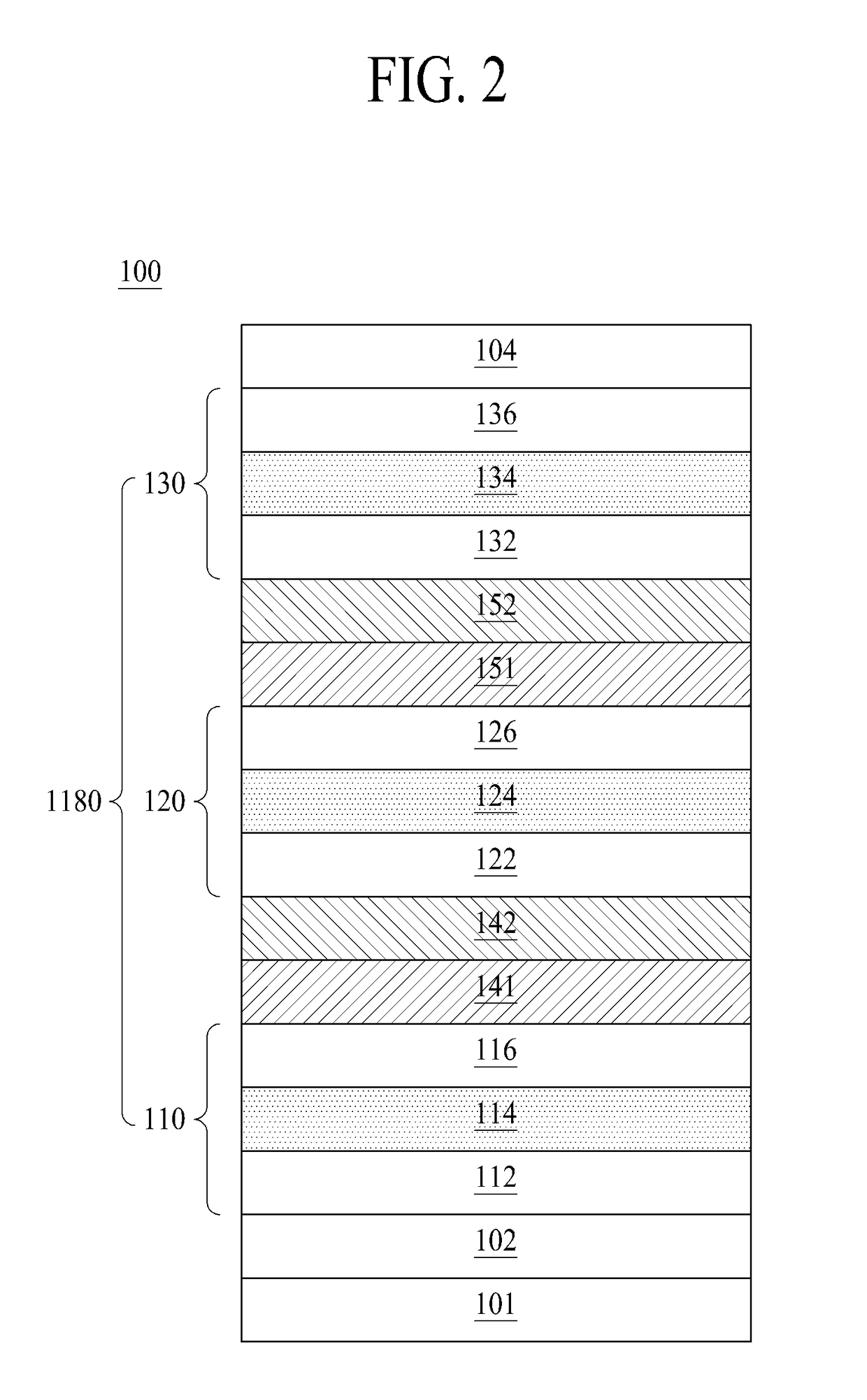

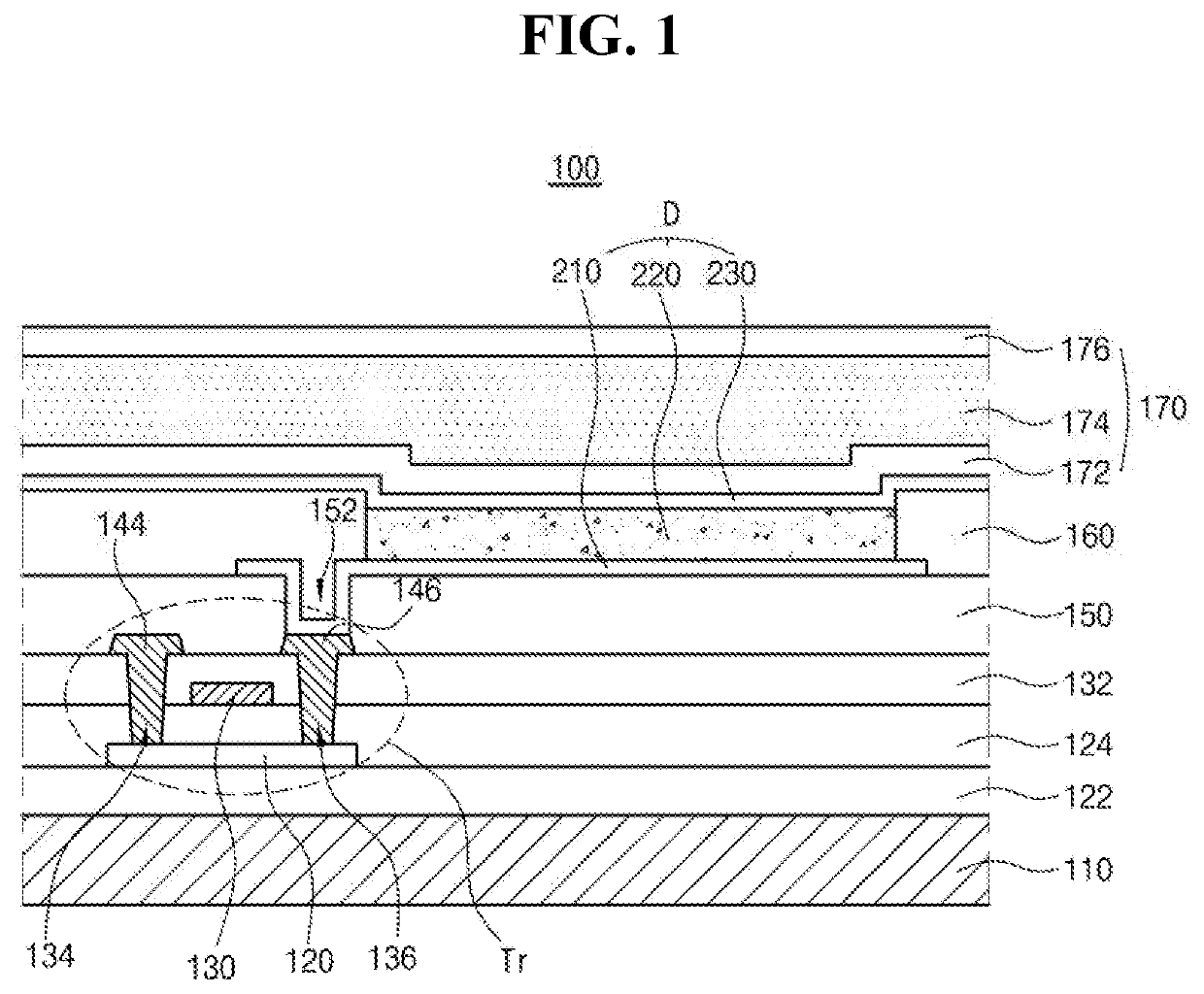

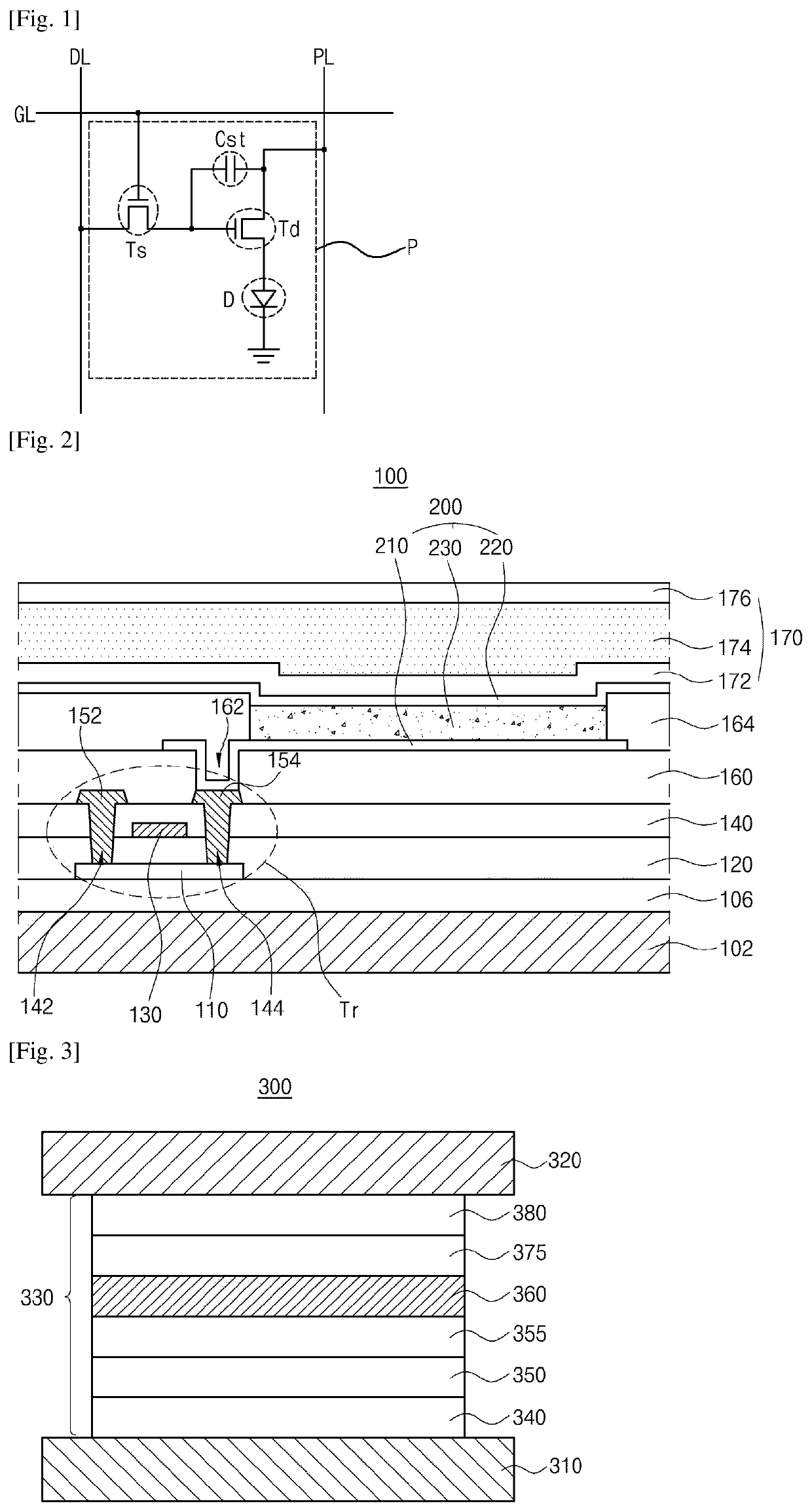

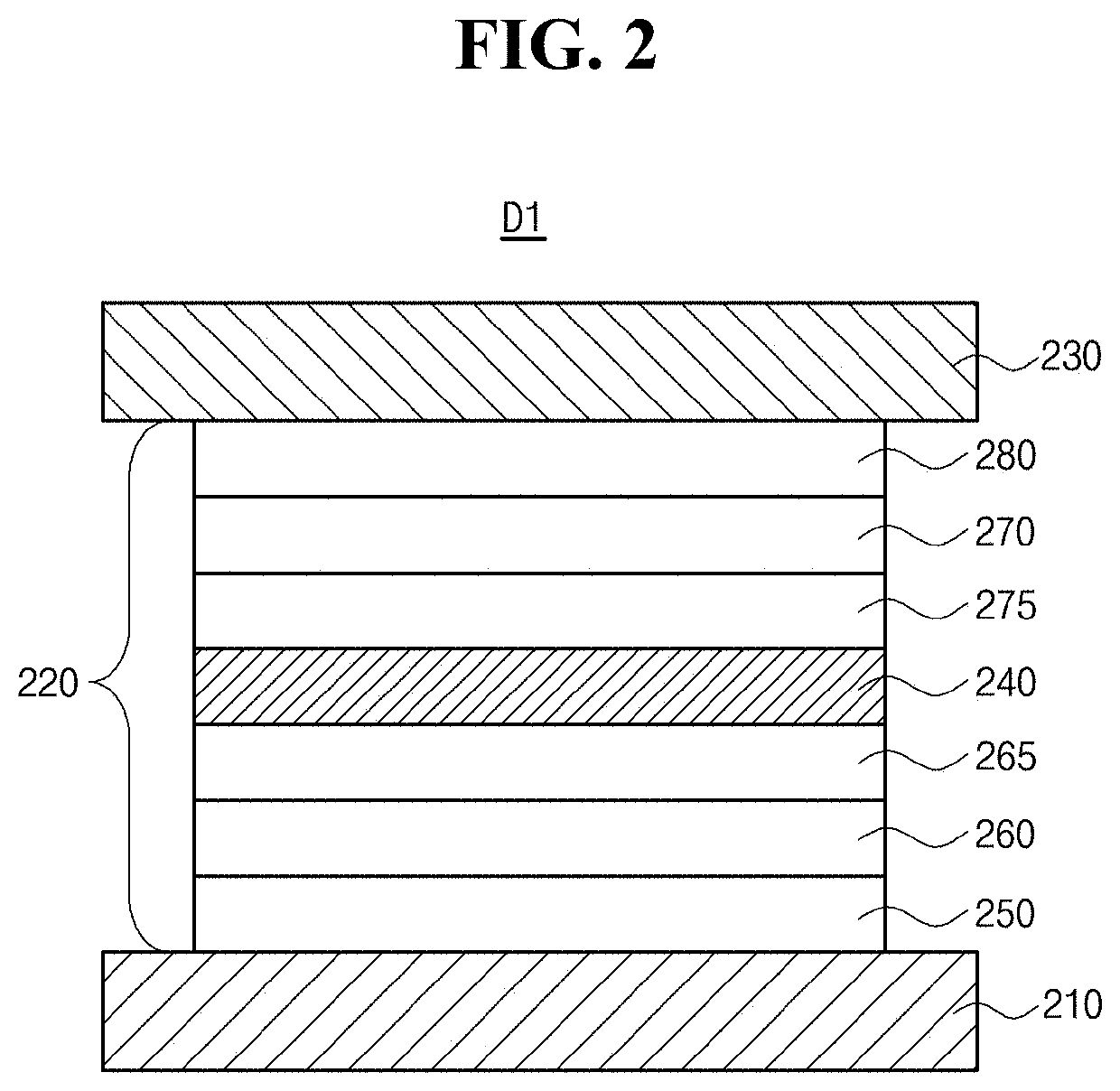

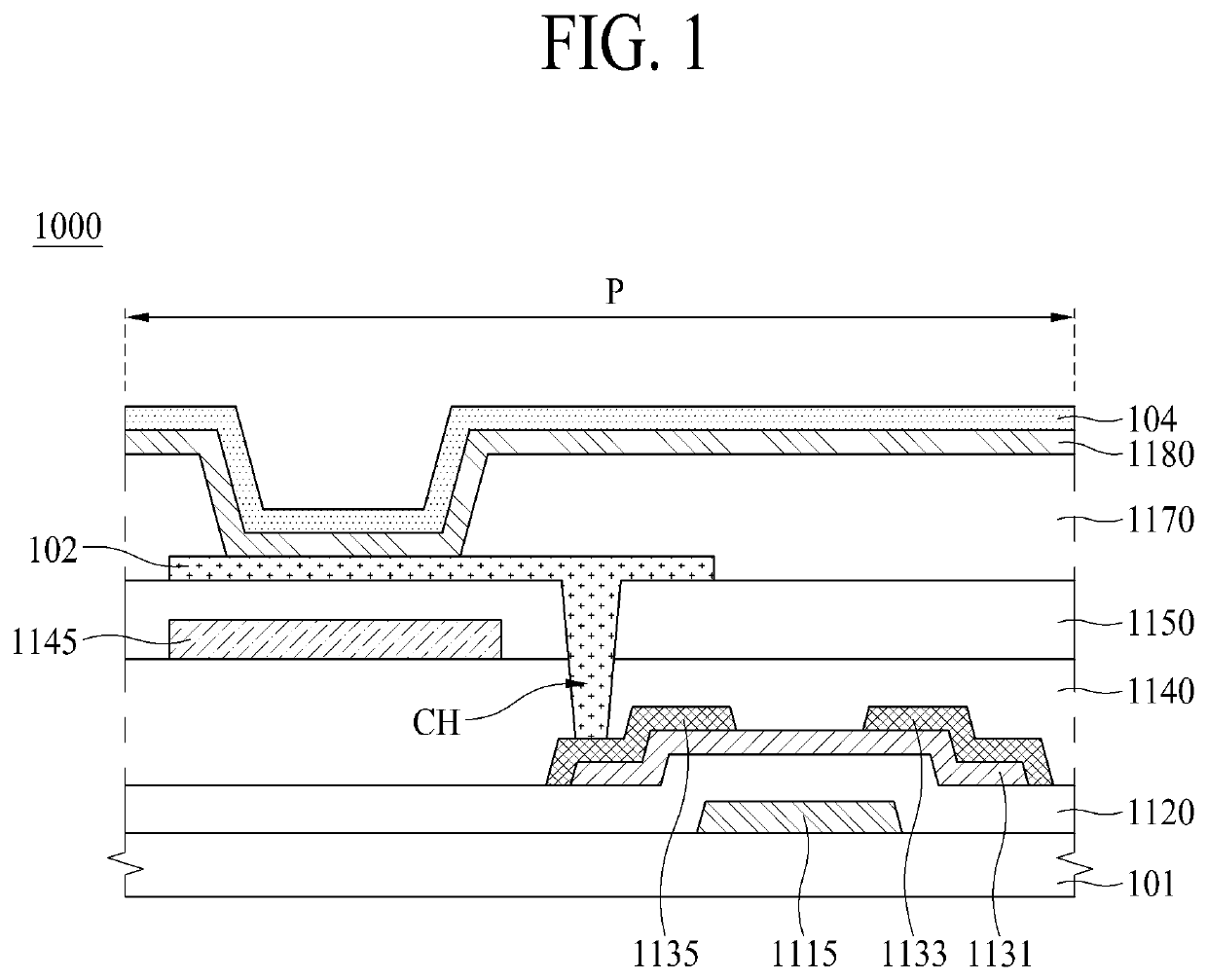

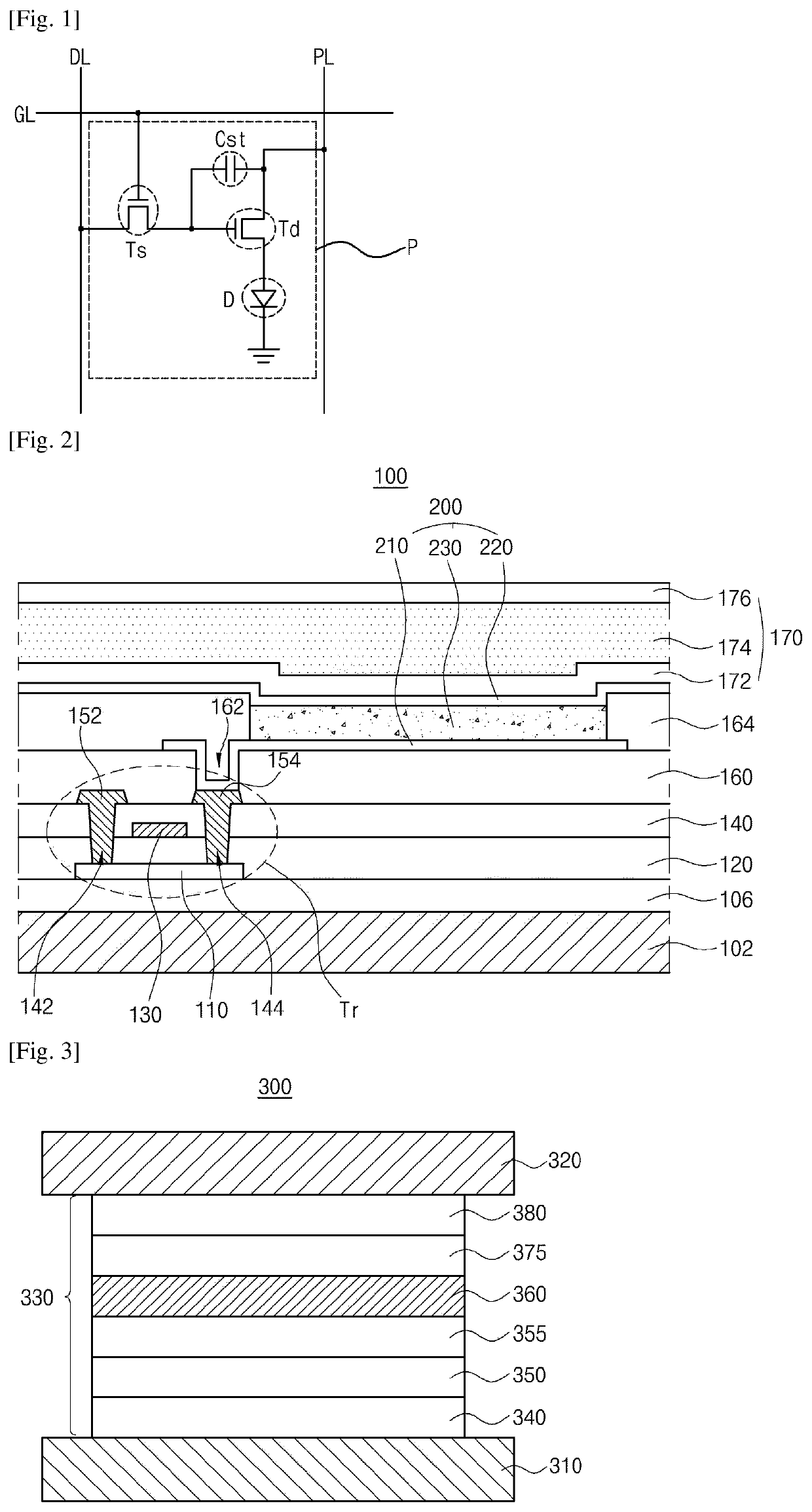

Organic light emitting device and method of fabricating the same

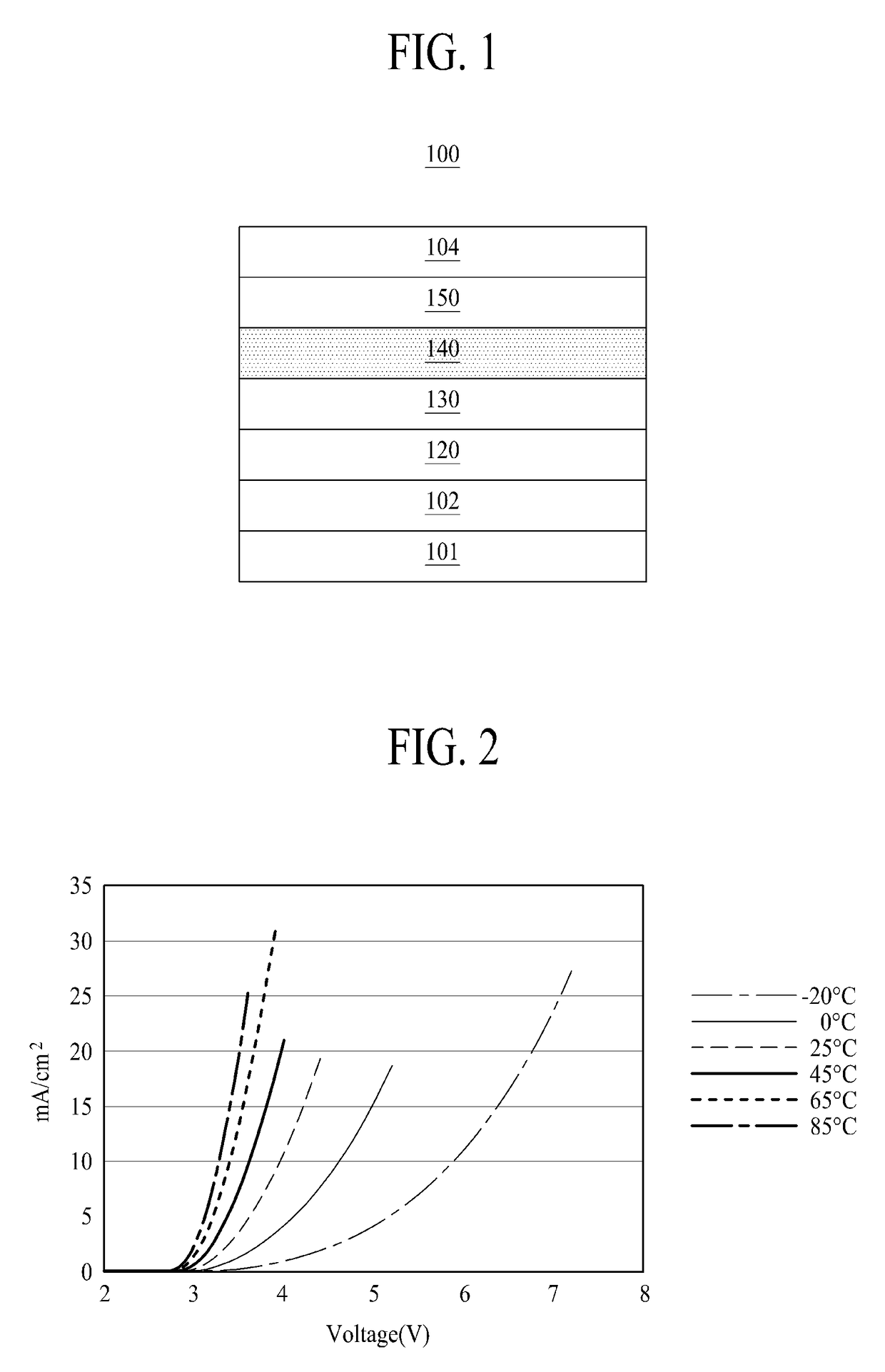

ActiveUS20160126297A1Quality improvementIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingBlue emissionOrganic light emitting device

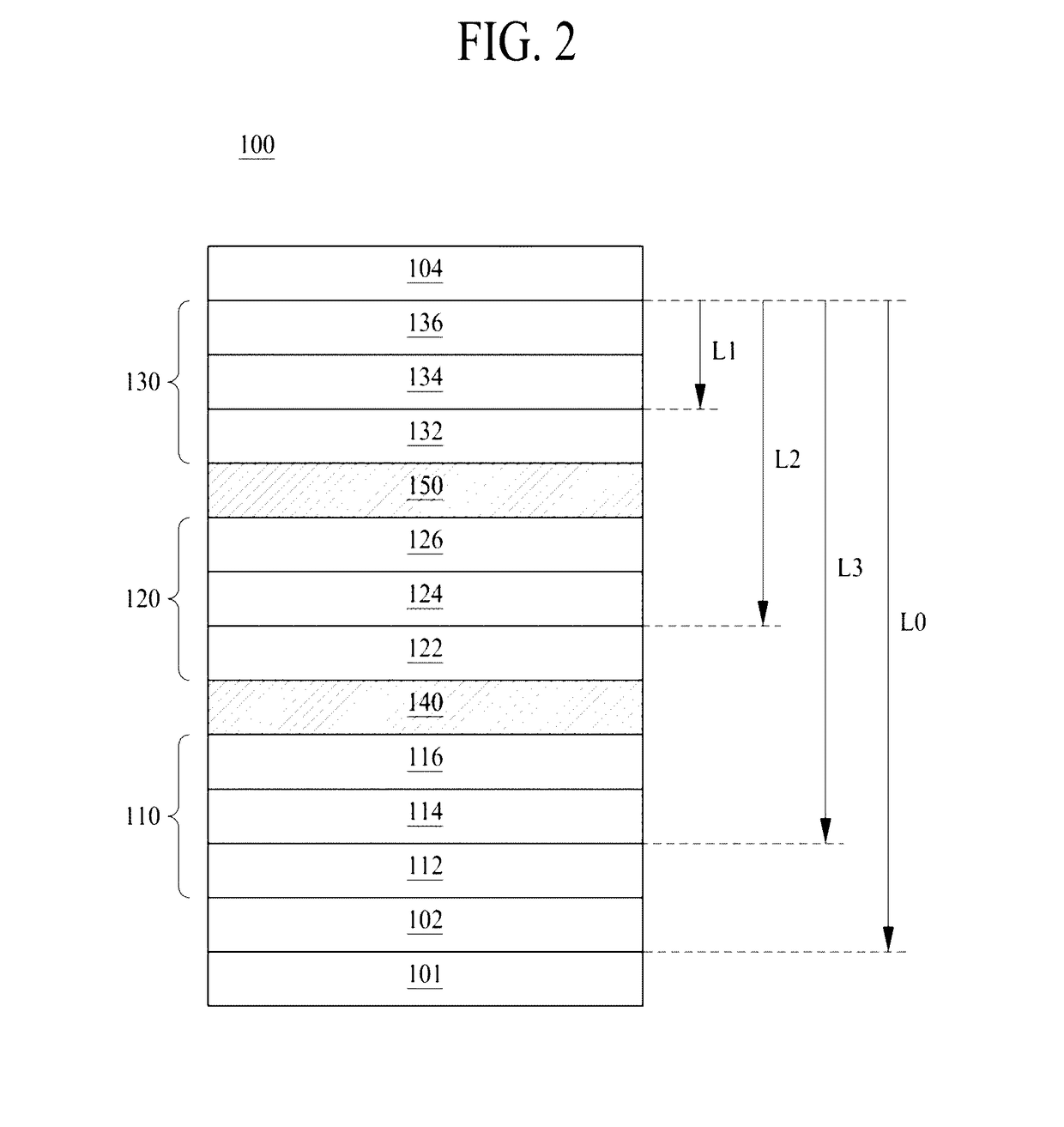

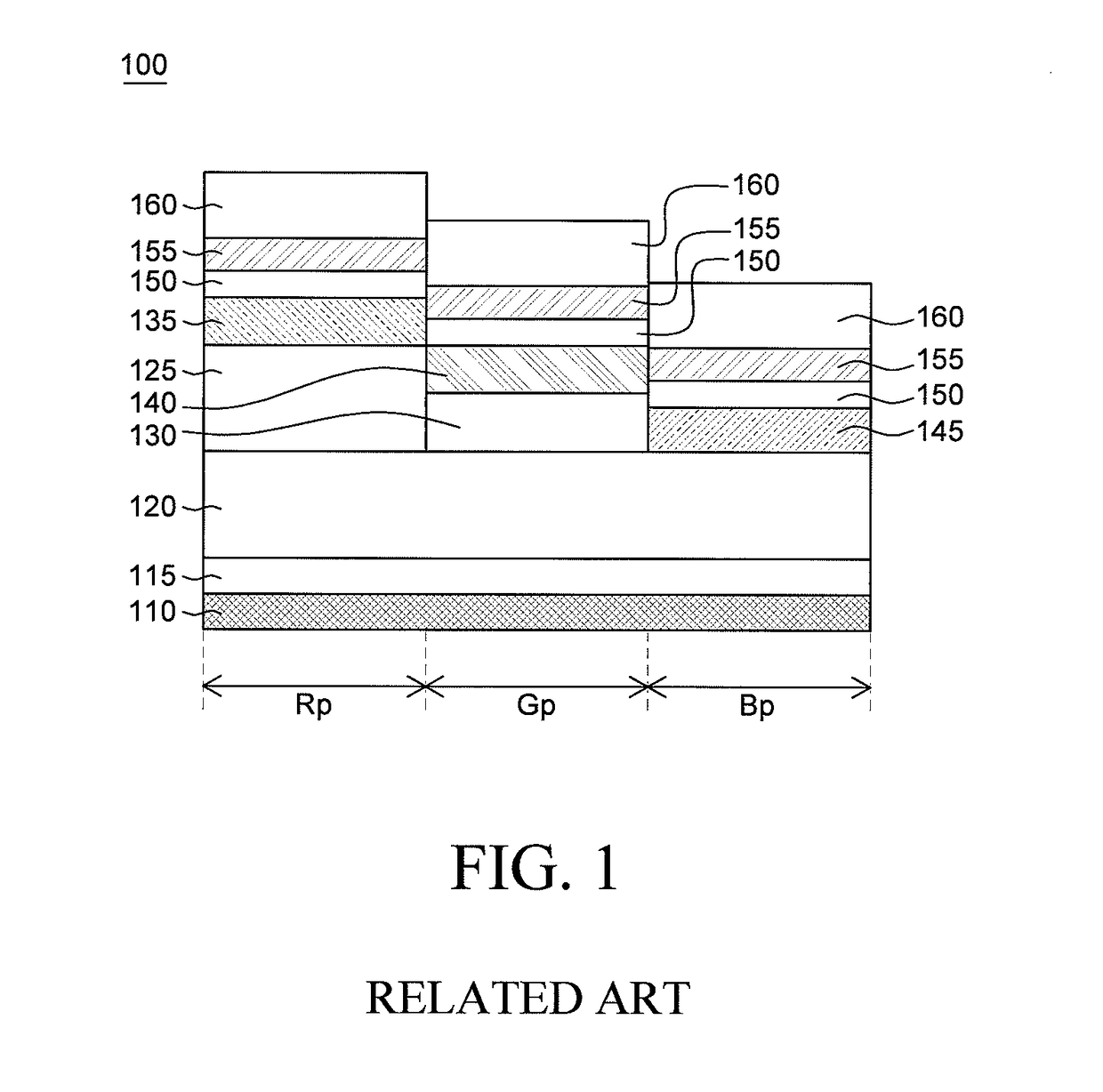

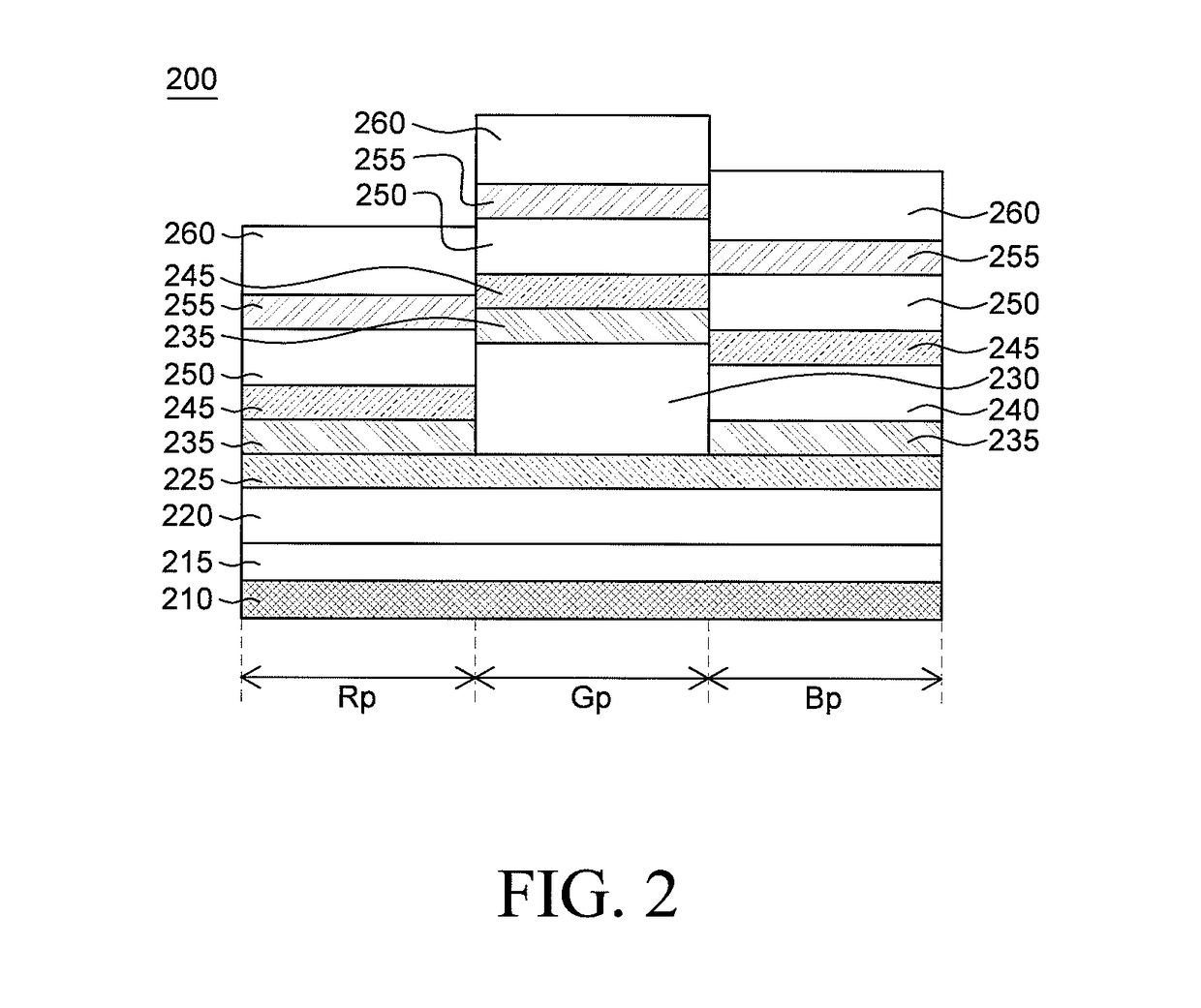

An organic light emitting device can include a first electrode and a second electrode, and a red emission layer, a green emission layer and a blue emission layer which are positioned between the first electrode and the second electrode. Each of the red emission layer, the green emission layer and the blue emission layer can be disposed in an entirety of a red sub-pixel area, a green sub-pixel area and a blue sub-pixel area. A distance between the first electrode and the second electrode in at least one of the red sub-pixel area, the green sub-pixel area and the blue sub-pixel area can be a first-order optical distance equal to λ / 2n, where λ is a wavelength of light emitted from each of the sub-pixel areas, and n is an average refractive index of a plurality of organic material layers disposed between the first electrode and the second electrode.

Owner:LG DISPLAY CO LTD

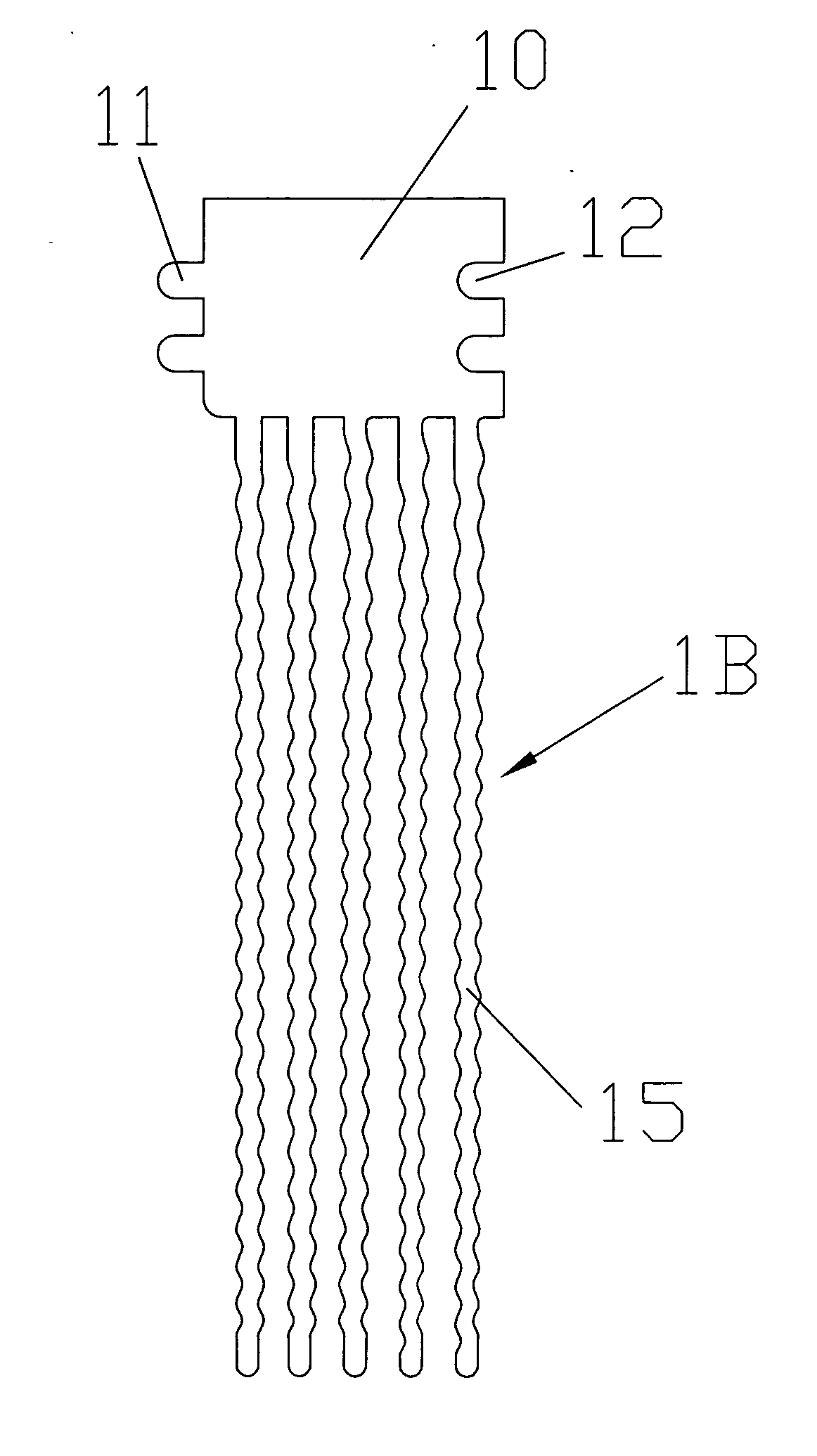

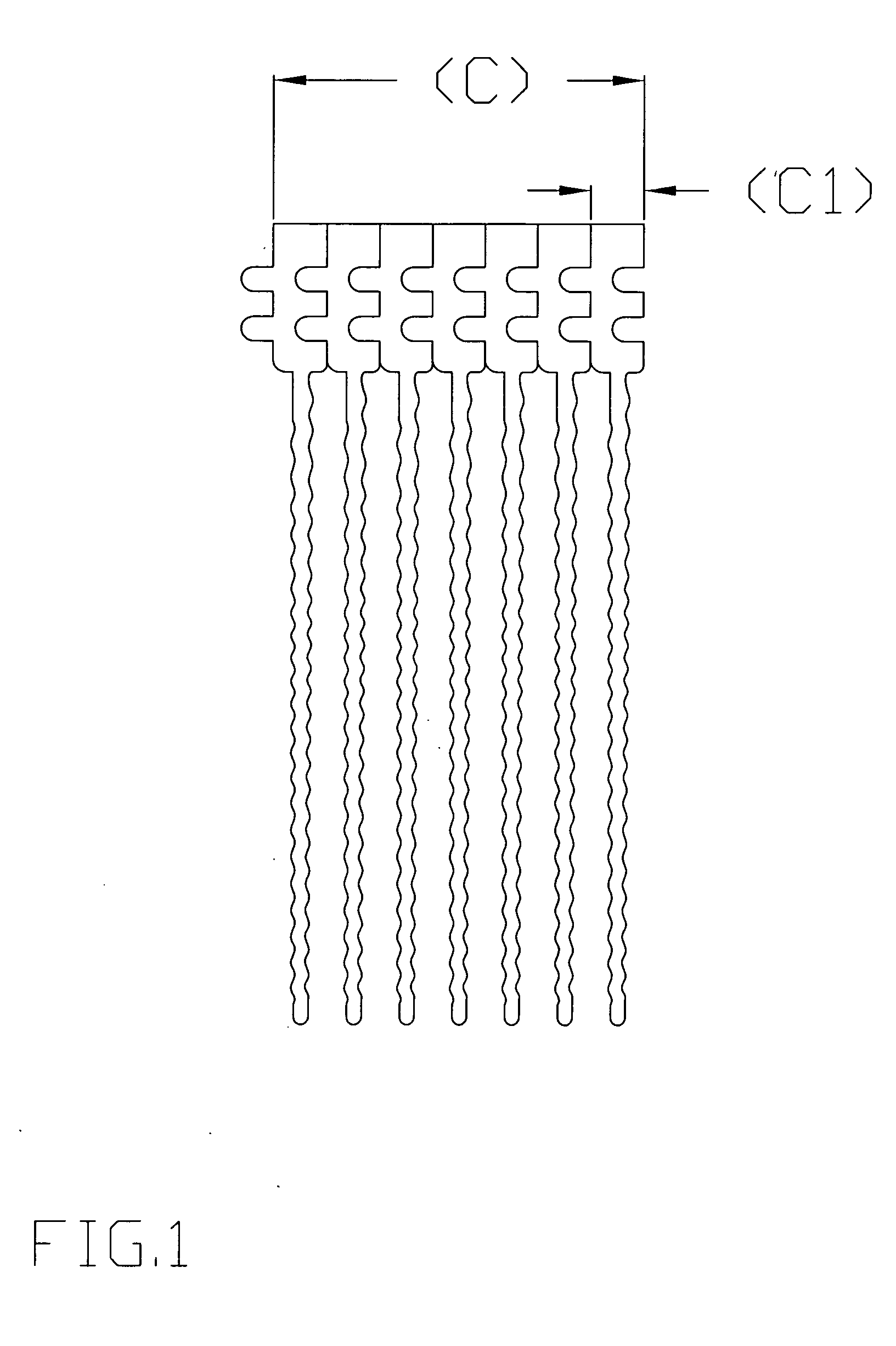

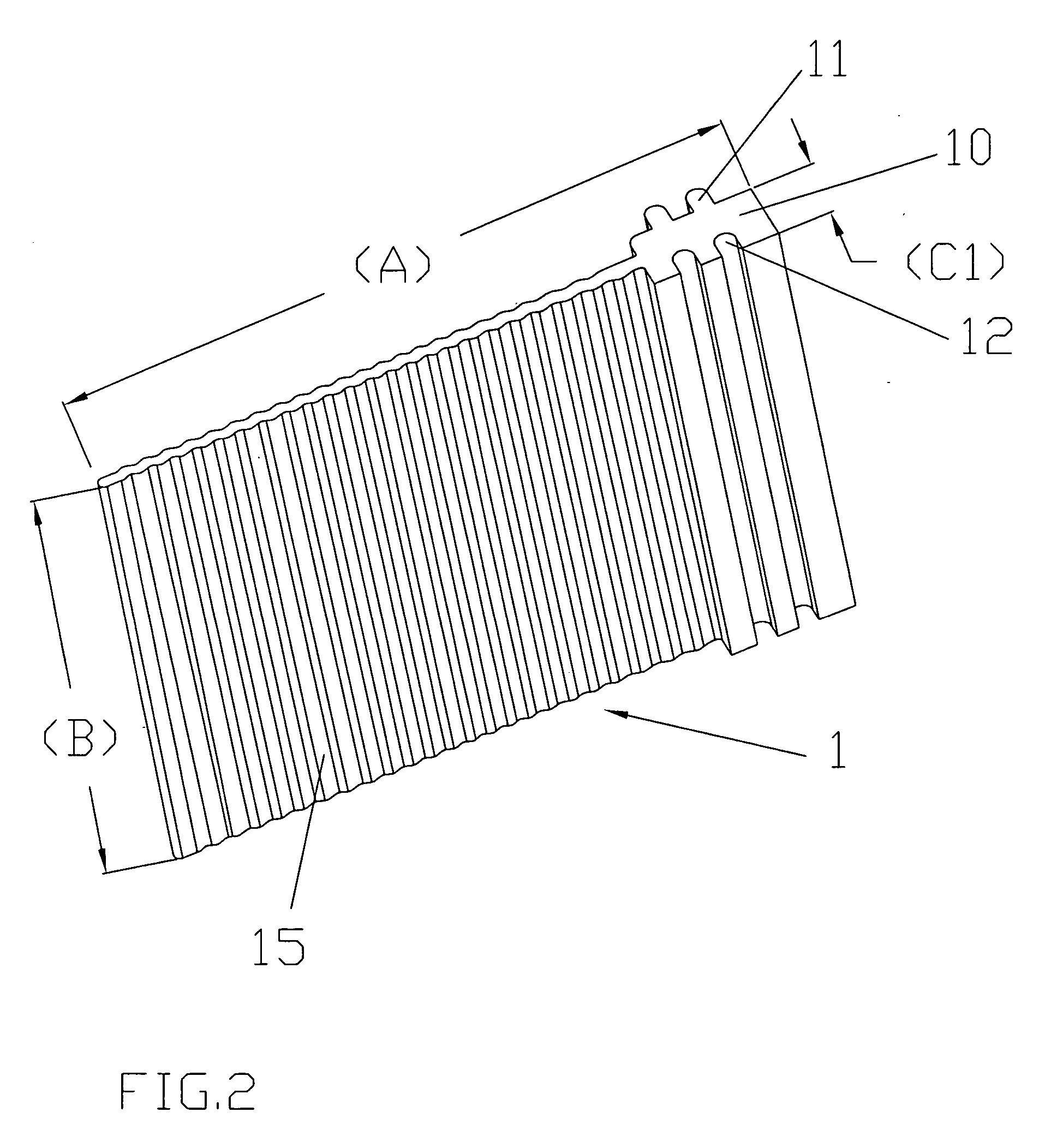

Composite heatsink plate assembly

InactiveUS20070223196A1Increase widthEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesMechanical engineering

A heatsink plate assembly includes a plurality of heatsink plates laminating each other. Each of the heatsink plates has a first side formed with at least one locking tenon and a second side formed with at least one locking mortise. Thus, the heatsink plates are laminated to have a determined width required by the heatsink plate assembly, so that the width of the heatsink plate assembly is increased according to the user's requirement without being limited to the width of the extruding machine, thereby facilitating fabrication of the heatsink plate assembly. In addition, each of the heatsink plates is made at a time without needing multiple working procedures, so that each of the heatsink plates is produced easily and rapidly, thereby decreasing costs of fabrication.

Owner:KUO MING SHO +1

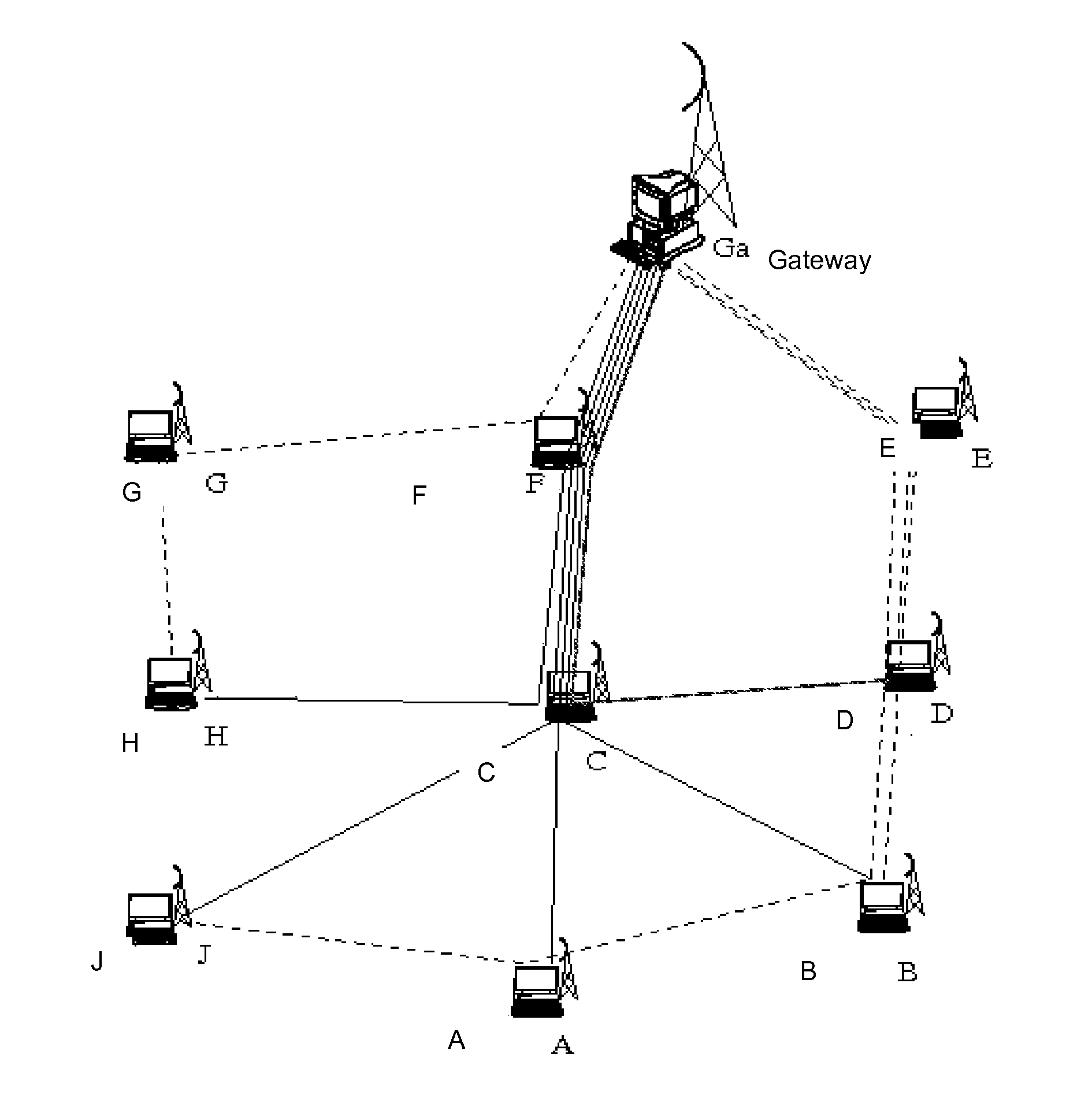

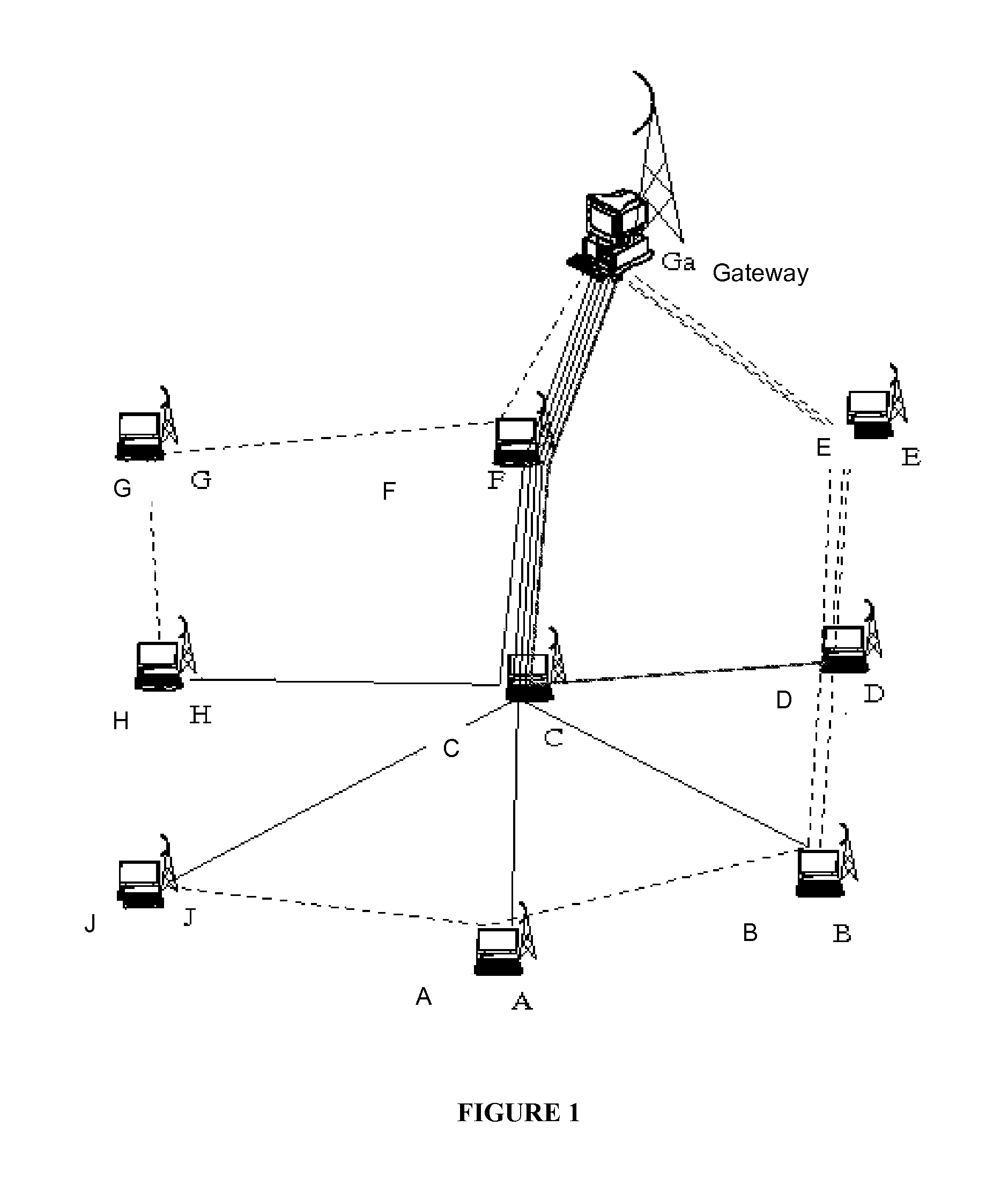

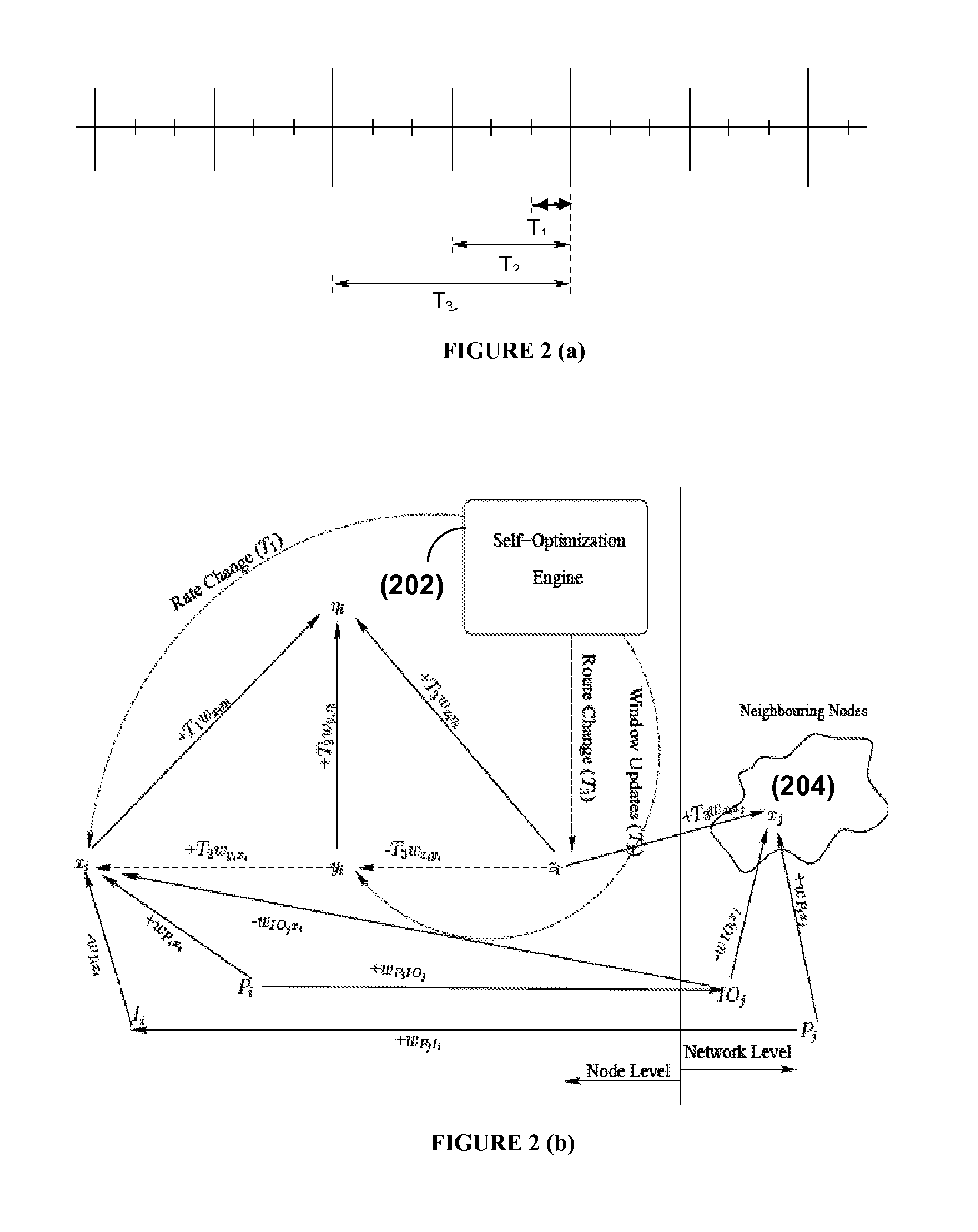

System and method for enhancing lifetime and throughput in a distributed wireless network

ActiveUS20130250812A1Enhancing lifetimeImprove throughputData switching by path configurationHigh level techniquesTransmission protocolInter layer

A system and method for enhancing lifetime and throughput in a distributed wireless network is disclosed herein. The method may include sensing, by a first machine, different parameters of at least one neighboring machine; updating, by the first machine, at least one parameter of said first machine based on said sensed parameters of said neighboring machine; generating, by the first machine, a signed-graph on the basis of the updated parameter, wherein said generated graph comprises at least two nodes representing said updated parameter and at least one edge interconnecting said two nodes; iteratively updating, by the first machine, the at least one parameter at different time-scales until convergence is achieved; and communicating, by the first machine, inter-layer updates in individual layers of a transmission protocol stack of the first machine due to said update of at least one parameter.

Owner:TATA CONSULTANCY SERVICES LTD

Organic electroluminescent device

InactiveUS20070120466A1High color purityLong life-timeDischarge tube luminescnet screensElectroluminescent light sourcesLength waveOrganic electroluminescence

An organic electroluminescent device including, a hole-transporting layer, an emitting layer and an electron-transporting layer in this order between an anode and a cathode, an emission spectrum having emission peaks when applying current for emission, the intensity (ID) of the maximum emission peak among the emission peaks and the intensity (IO) of another emission peak at a shorter wavelength than the wavelength of the maximum emission peak among the emission peaks satisfying the following formula (A), IO / ID<1 / 50 (A).

Owner:IDEMITSU KOSAN CO LTD

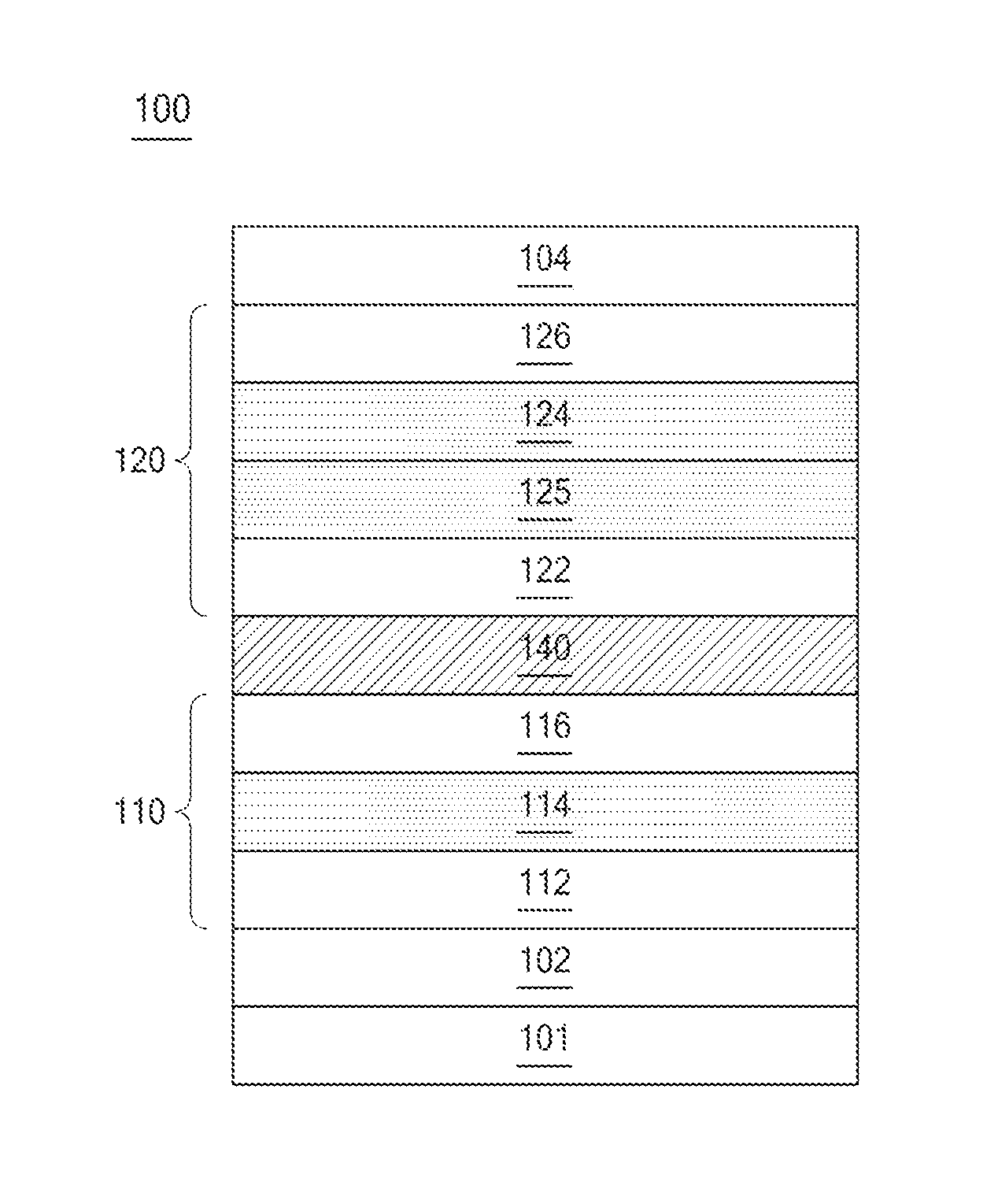

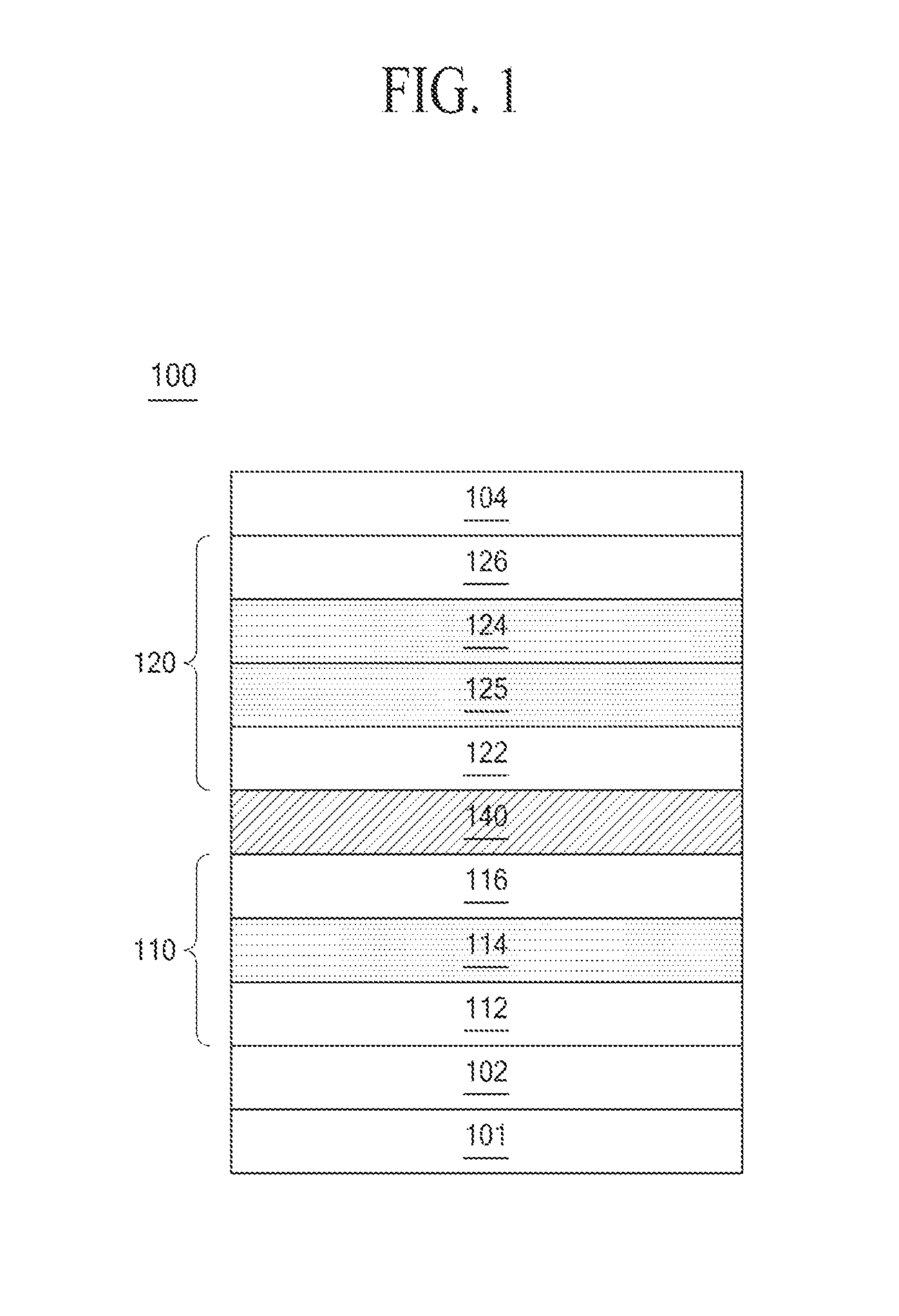

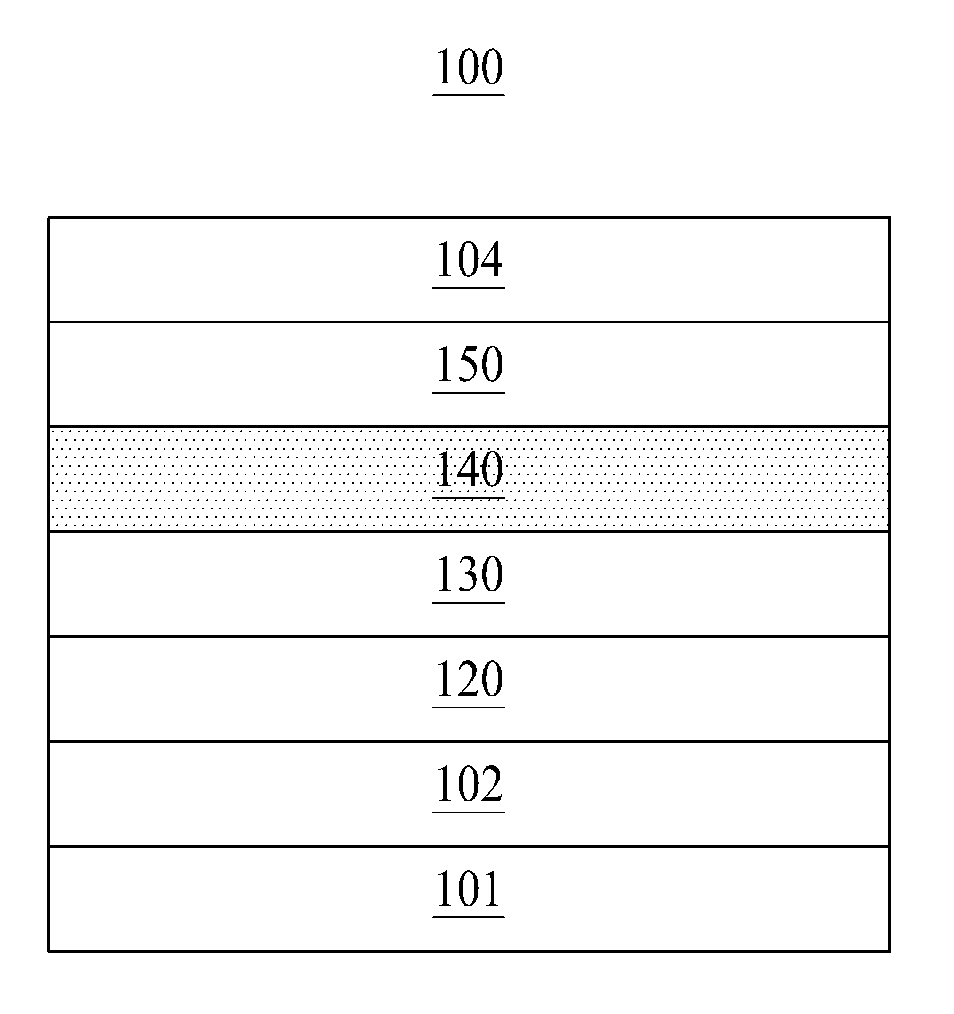

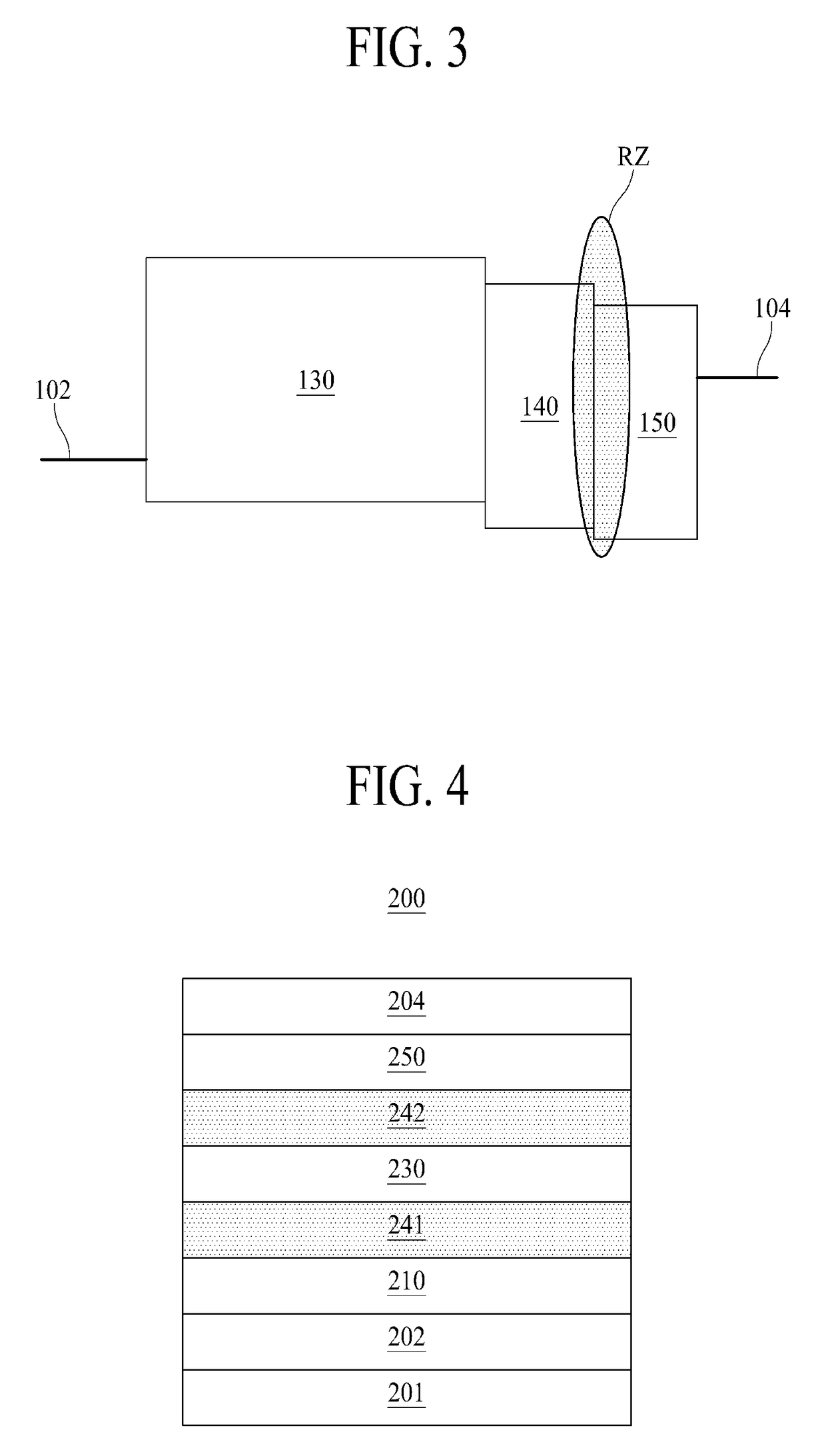

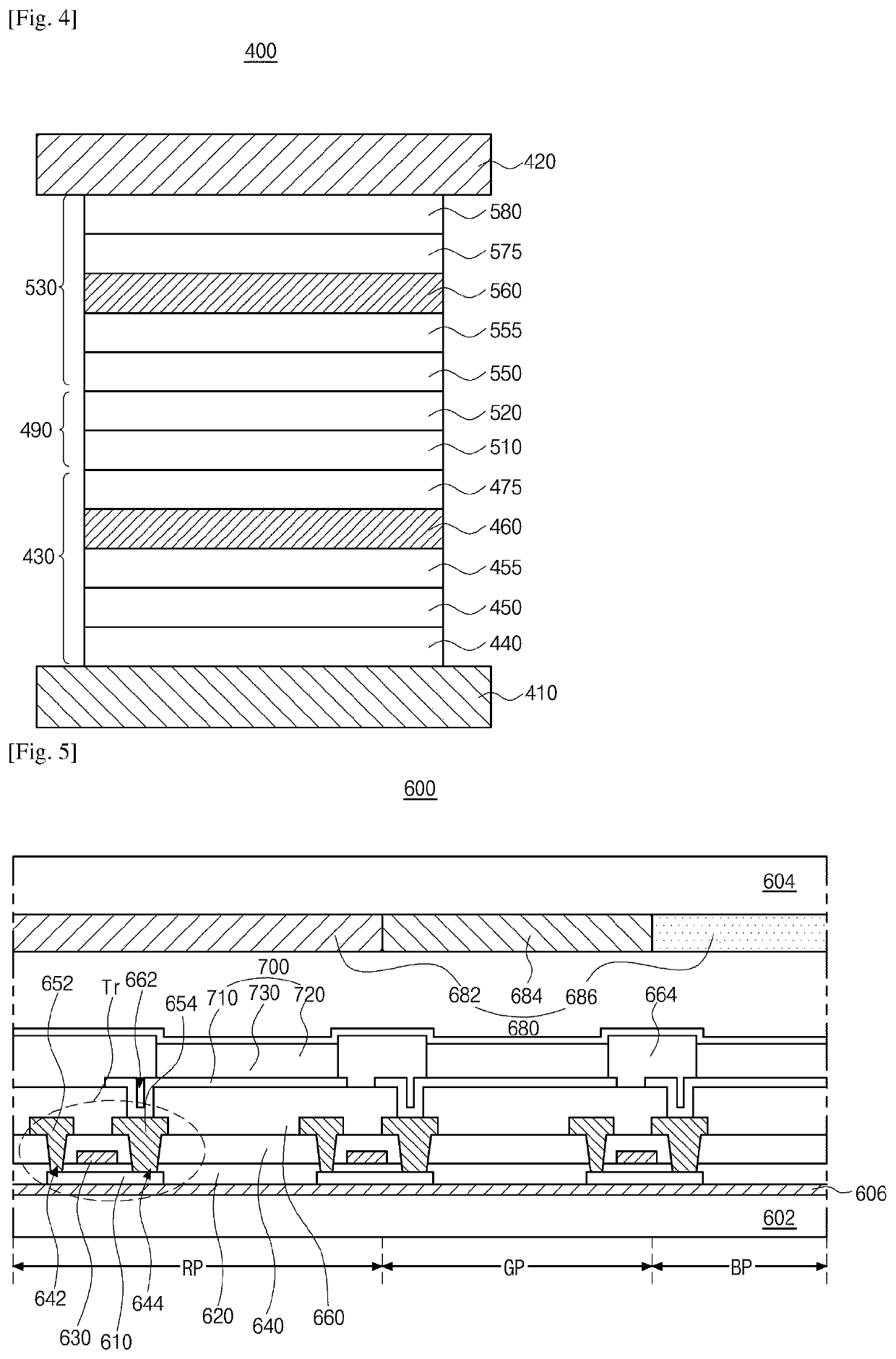

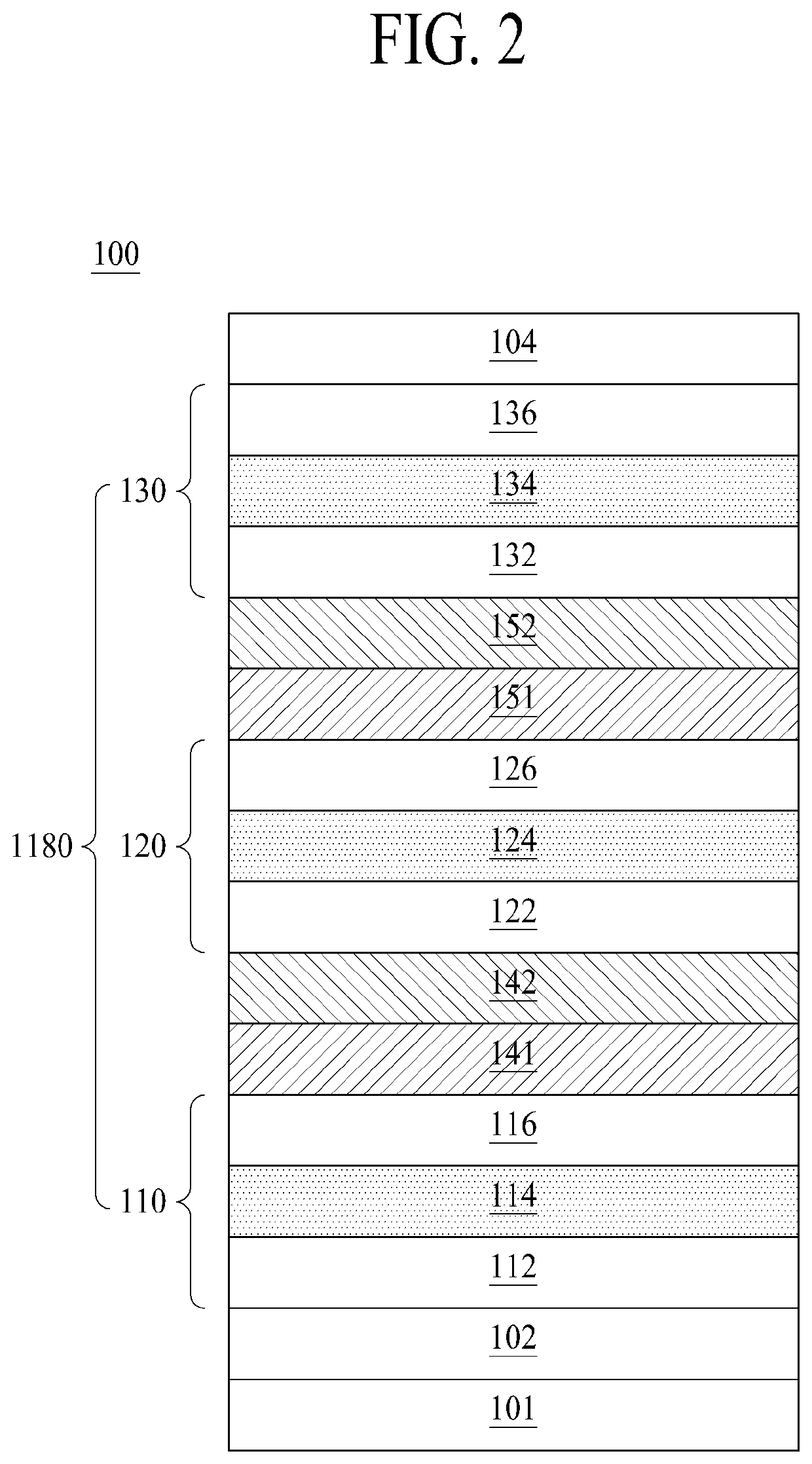

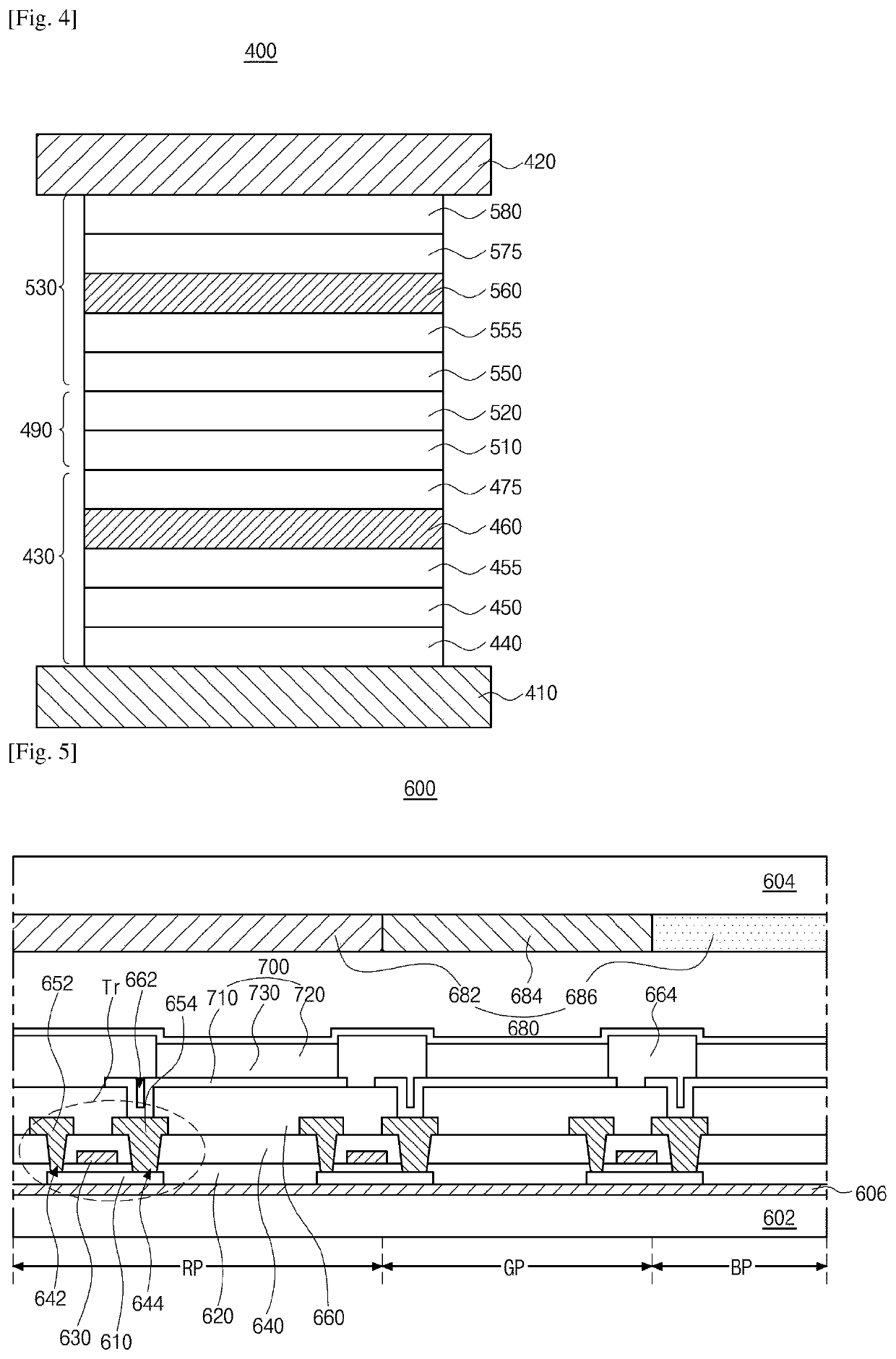

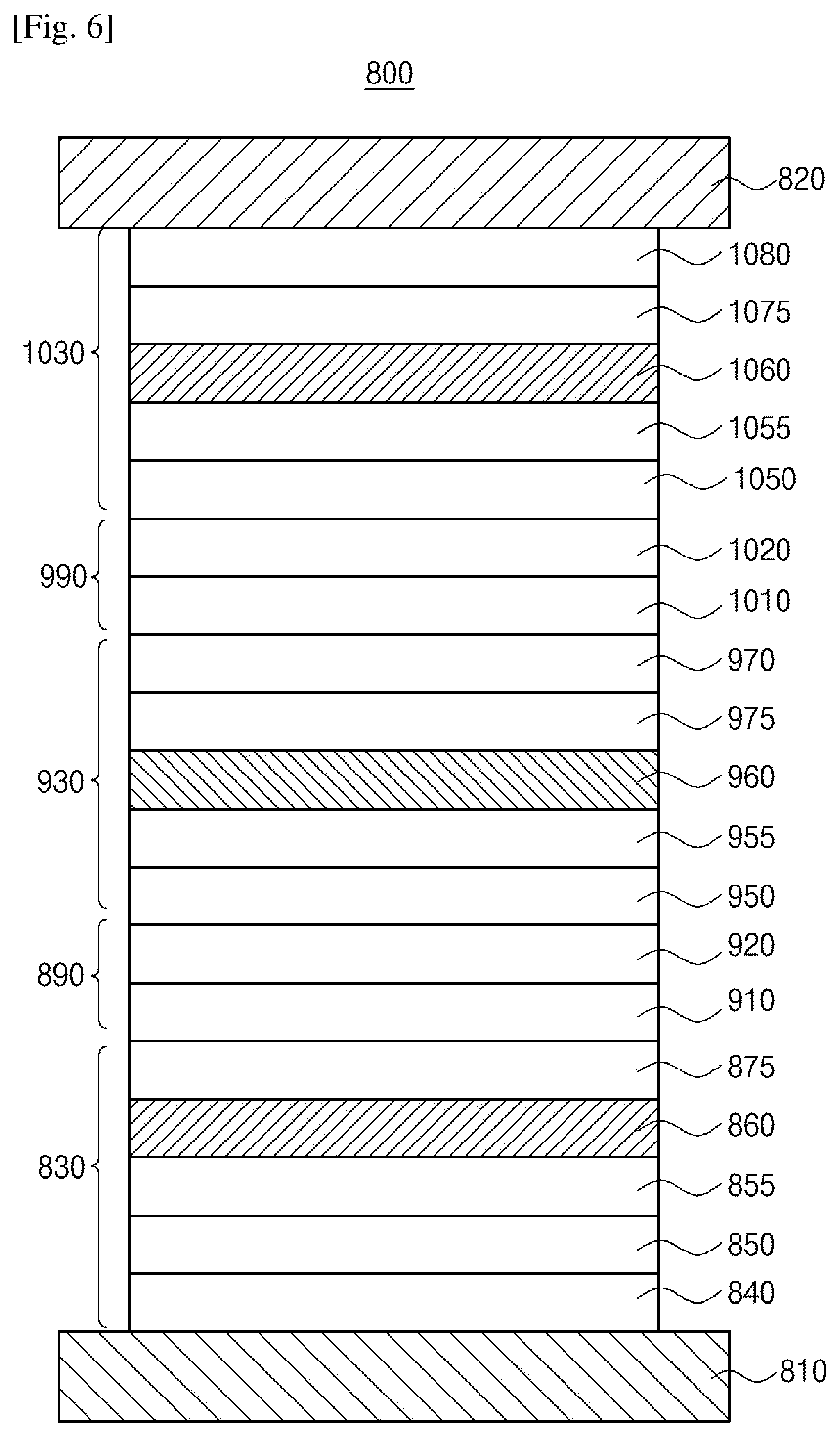

White organic light emitting device

ActiveUS20150311462A1Small increase in lifetime of deviceIncrease manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingControl layerOrganic light emitting device

Disclosed is a white organic light emitting device in which a lifetime of a device is enhanced. The white organic light emitting device includes a first emission part between a first electrode and a second electrode and a second emission part on the first emission part. At least one among the first and second emission parts includes an emission area control layer. The white organic light emitting device includes a first emission part between a first electrode and a second electrode, a second emission part on the first emission part, and a third emission part on the second emission part. At least one among the first to third emission parts includes an emission area control layer.

Owner:LG DISPLAY CO LTD

Polyolefin Construction

InactiveUS20110236708A1Reduce the number of layersReduce chanceSynthetic resin layered productsLaminationPolymer sciencePolyolefin

A polyolefin construction comprising at least one polyolefin (PO) layer, a barrier layer for the polyolefin layer and a compatibiliser for the PO and the barrier layer, which compatibiliser enables the PO and barrier layer to adhere together, whereby the barrier layer comprises the compatibiliser; a blended barrier layer polymer and the barrier layer formed therefrom and a process for producing the polyolefin construction.

Owner:BOREALIS AG

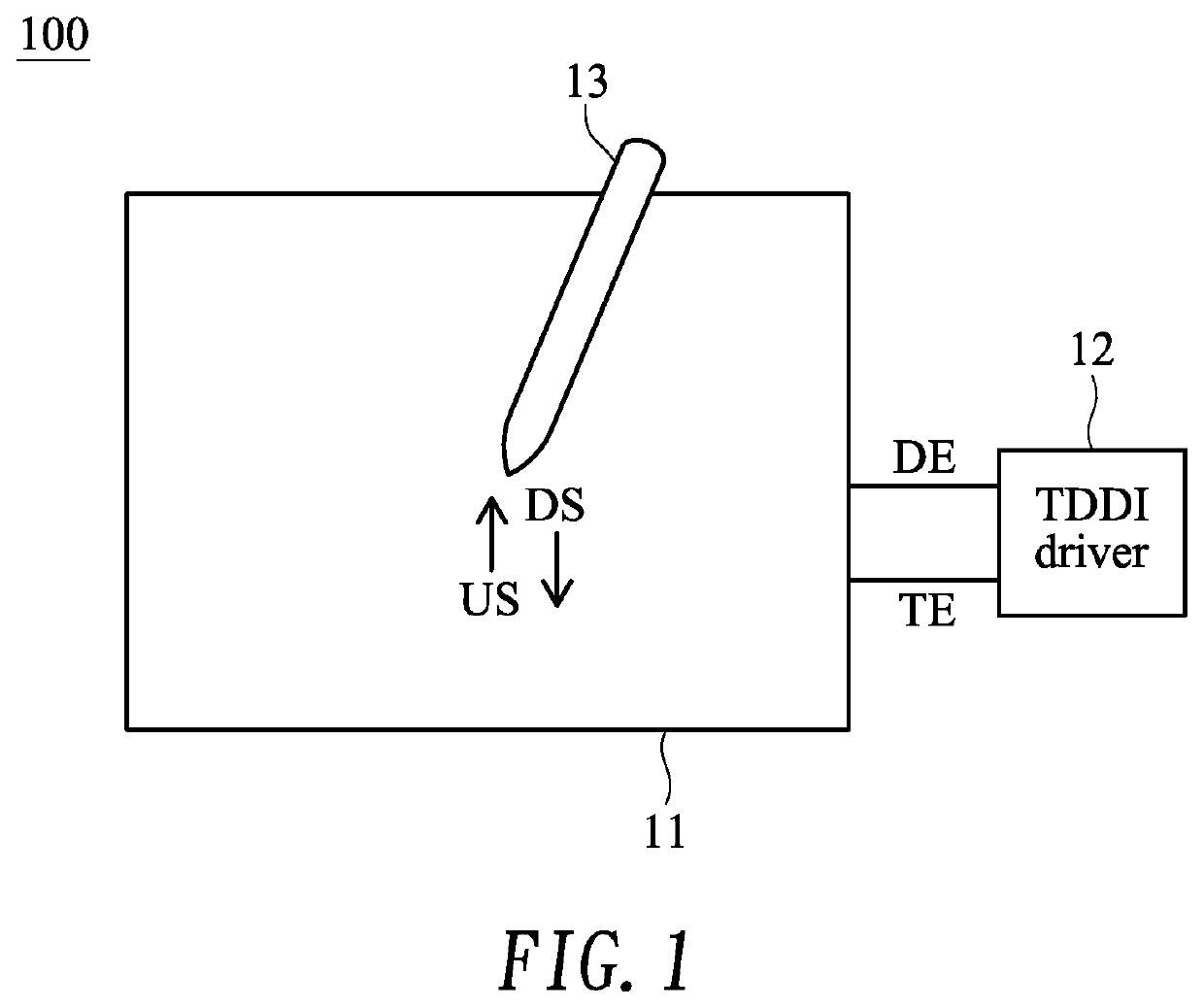

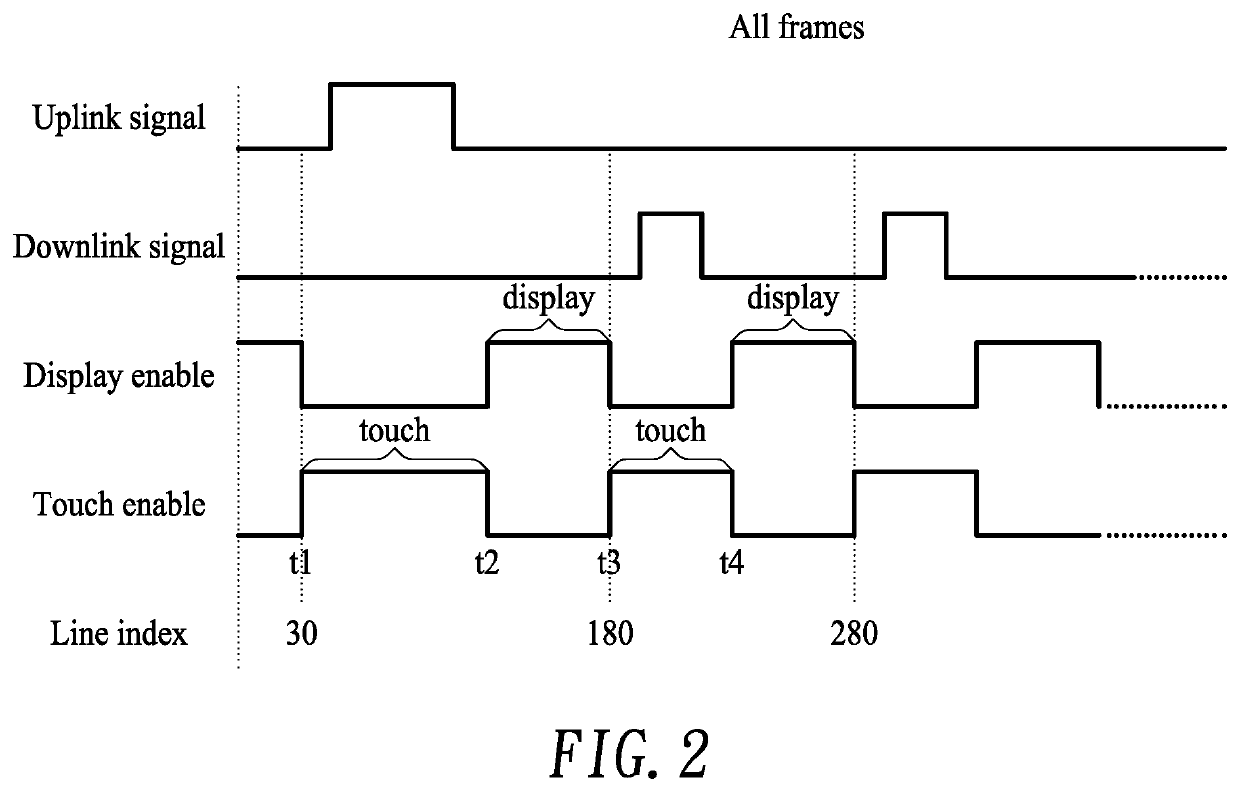

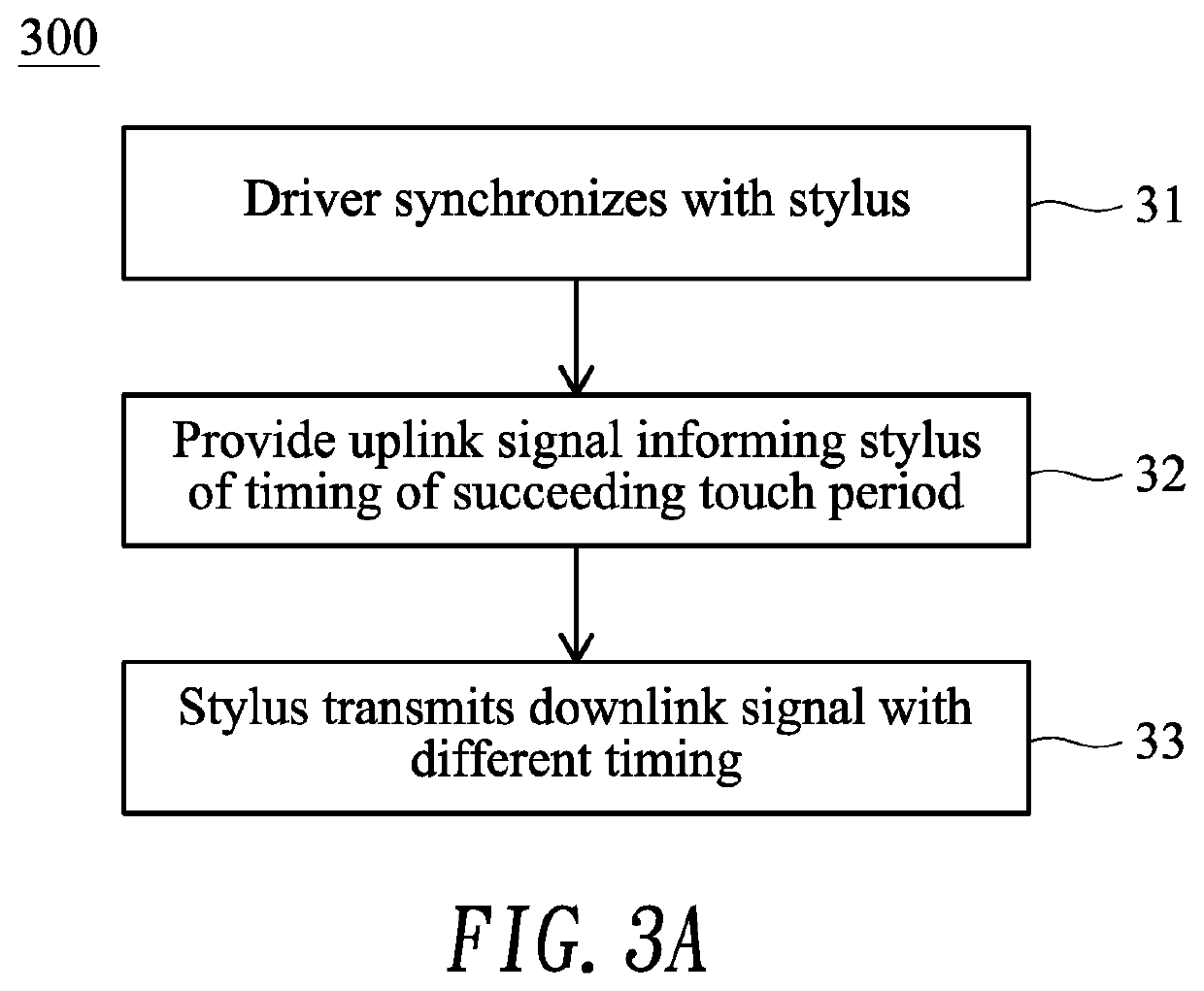

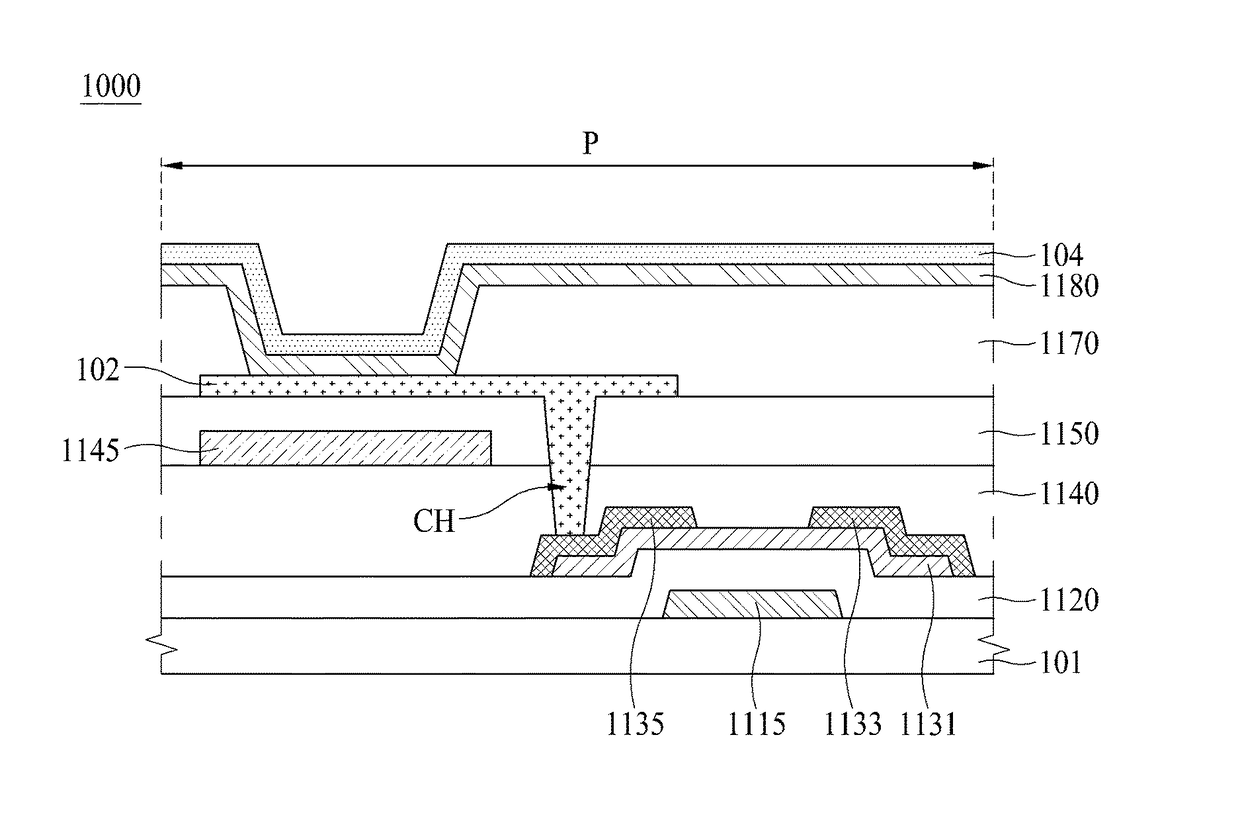

Position input system and method

ActiveUS10739909B1Improve reliabilityEnhancing lifetimeCathode-ray tube indicatorsInput/output processes for data processingComputer hardwareTouchscreen

A position input system includes a touch screen, an active stylus and a driver. The driver transmits an uplink signal to the active stylus via the touch screen in a current touch period, the uplink signal containing timing information that informs the active stylus of timing of a next touch period in which the active stylus transmits a downlink signal to the driver via the touch screen. In another embodiment, the driver transmits an uplink signal to the active stylus via the touch screen in a current touch period of a current frame at a time different from a corresponding touch period of a previous frame.

Owner:HIMAX TECH LTD

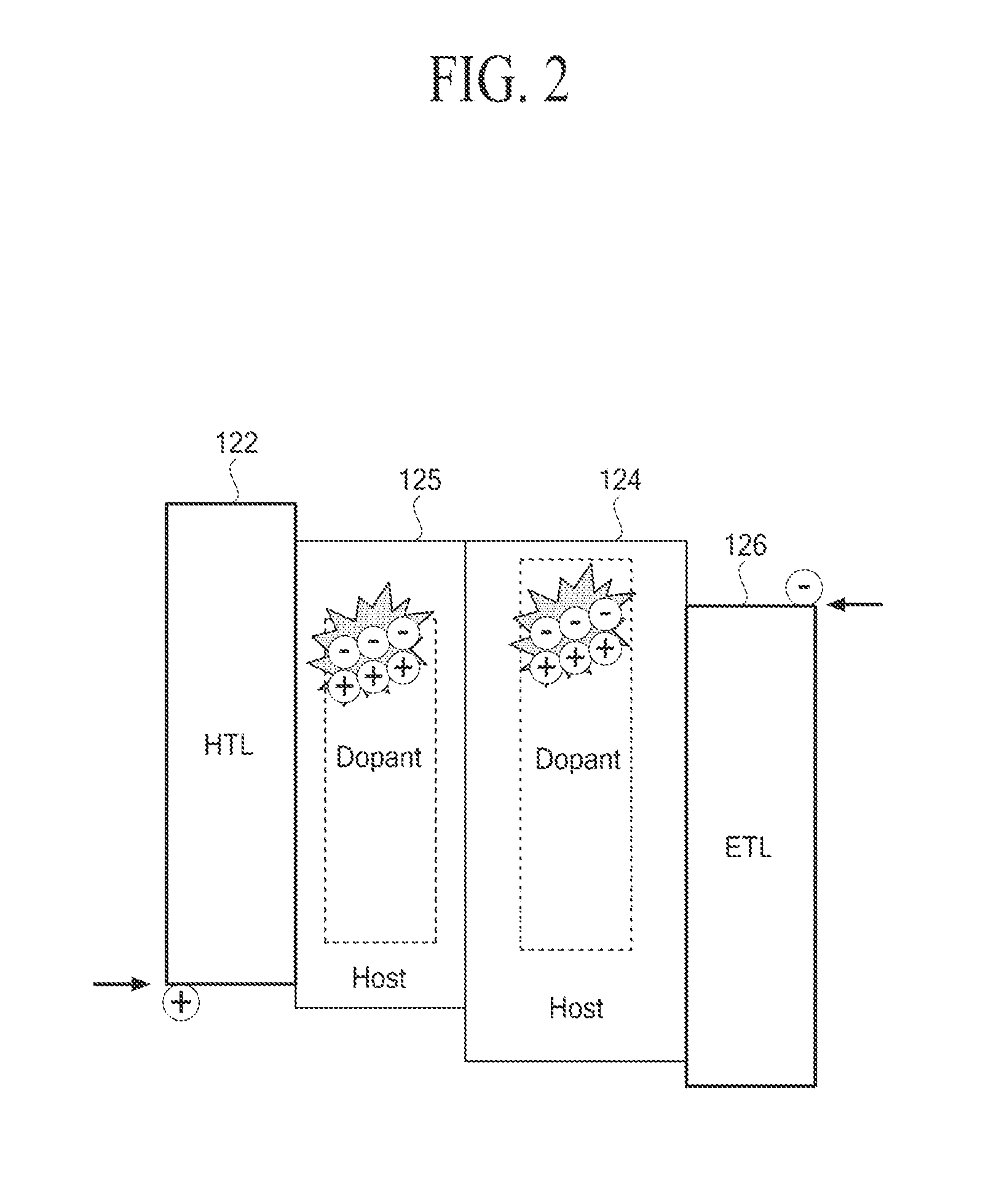

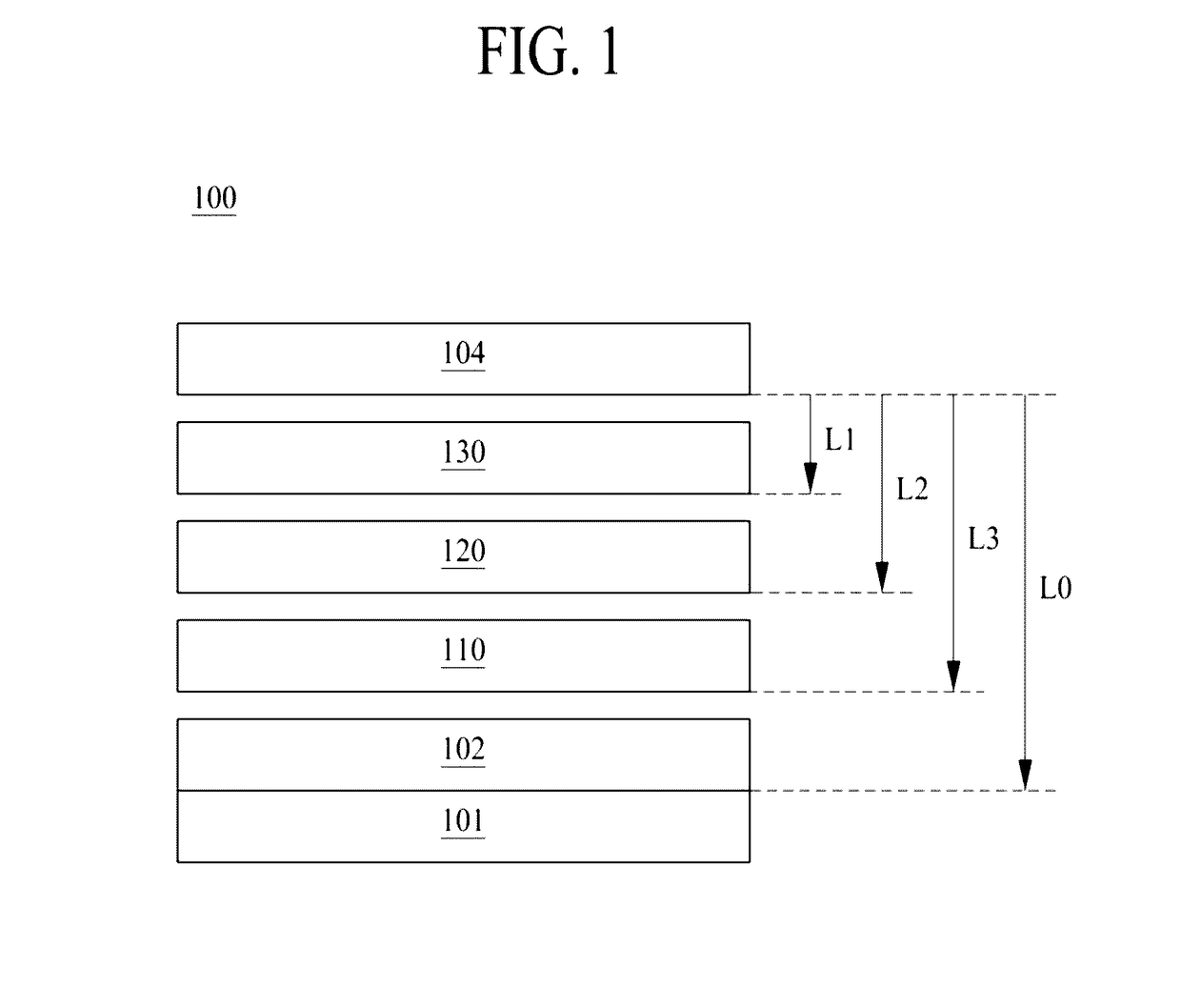

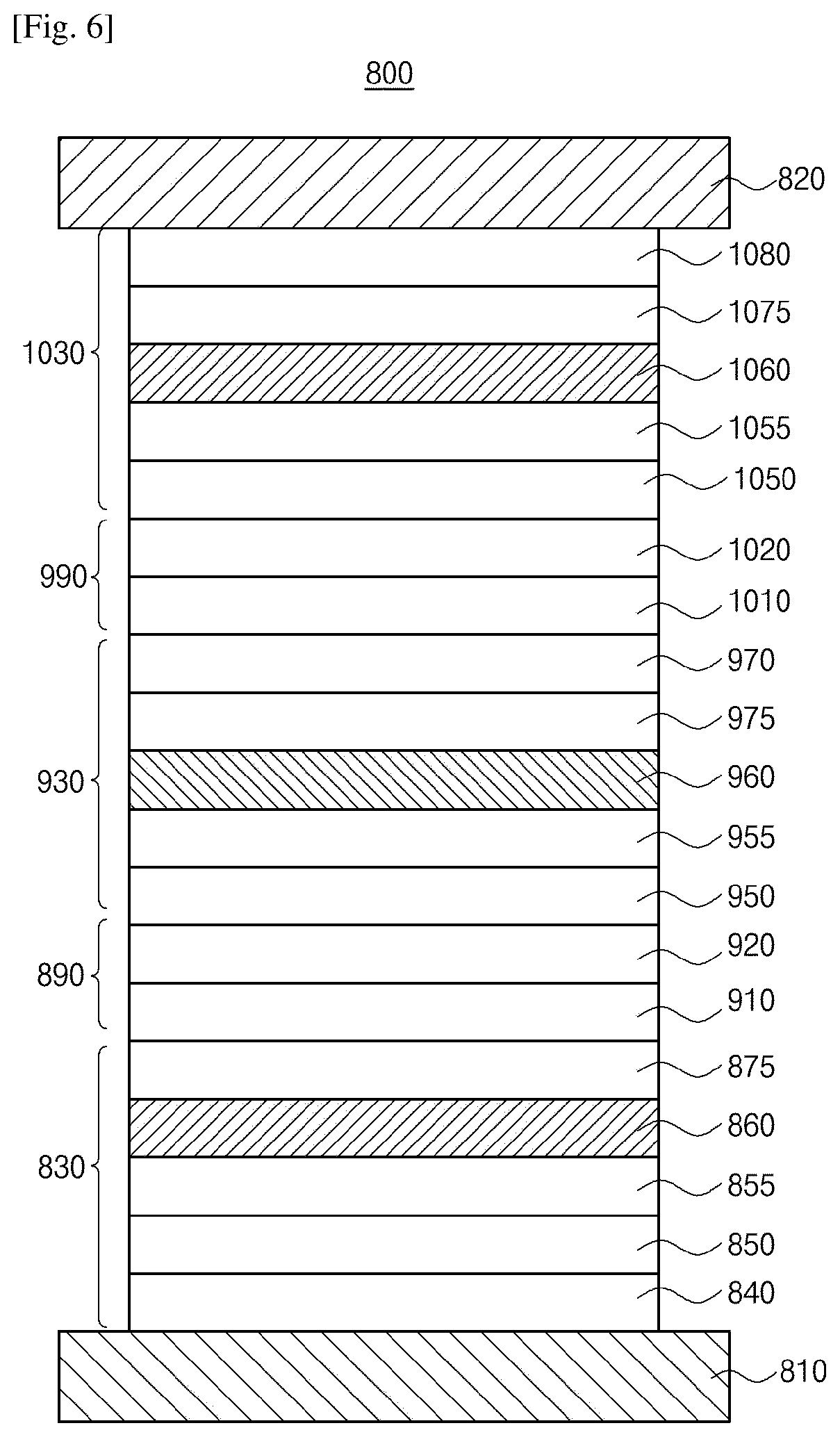

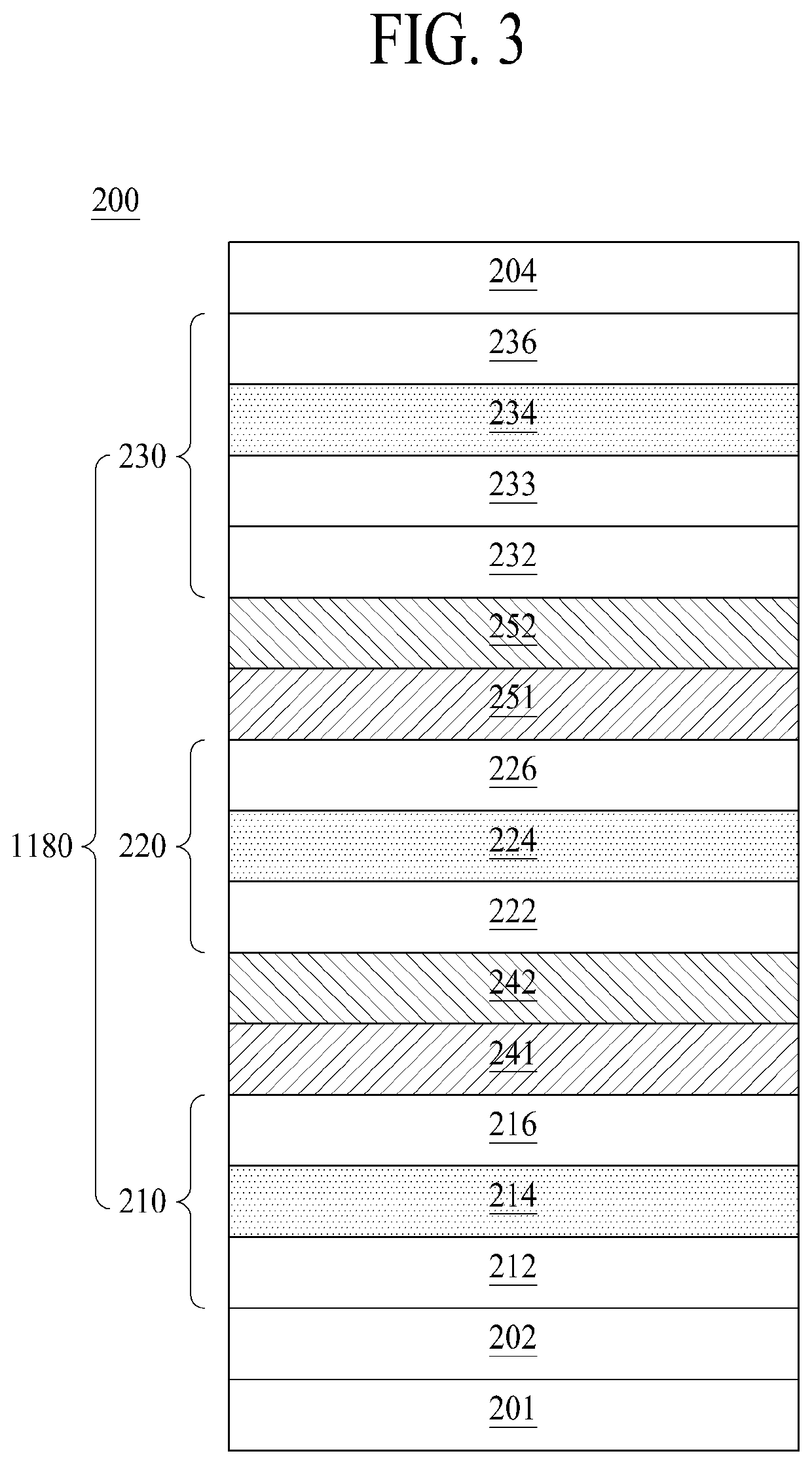

Organic light emitting display device

ActiveUS20170155071A1Improve efficiencyEnhancing lifetimeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceHole transport layer

Discussed is an organic light emitting display device. The organic light emitting display device can include a first emission part, a second emission part on the first emission part, and a first P-type charge generation layer between the first emission part and the second emission part. The first emission part includes a first hole transport layer, a first emission layer, and a first electron transport layer. The second emission part includes a second hole transport layer, a second emission layer, and a second electron transport layer. The second hole transport layer and the first P-type charge generation layer are disposed adjacent to each other. The second hole transport layer includes a first material and a second material. The first material has an absolute value of a HOMO energy level which can be greater than an absolute value of a LUMO energy level of the first P-type charge generation layer.

Owner:LG DISPLAY CO LTD

Laundry machine

ActiveUS20100083712A1Easy opening/closing of a doorEasy to useOther washing machinesControl devices for washing apparatusEngineeringLaundry

The present invention relates to laundry machines, and, more particularly, to a safe laundry machine which enables a user to open / close a door easily, and can prevent an accident caused by opening / closing of the door from taking place.The laundry machine includes a cabinet, a drum rotatably mounted in the cabinet, a door having a latch for being opened / closed selectively to expose an inside of the drum to an outside of the laundry machine, and a door switch assembly provided for enabling opening / closing of the door, wherein the door switch assembly includes a switch unit for making selective connection to the latch, and an opening operation unit spaced from the switch unit for the user to enable to disconnect the connection between the latch and the switch unit.

Owner:LG ELECTRONICS INC

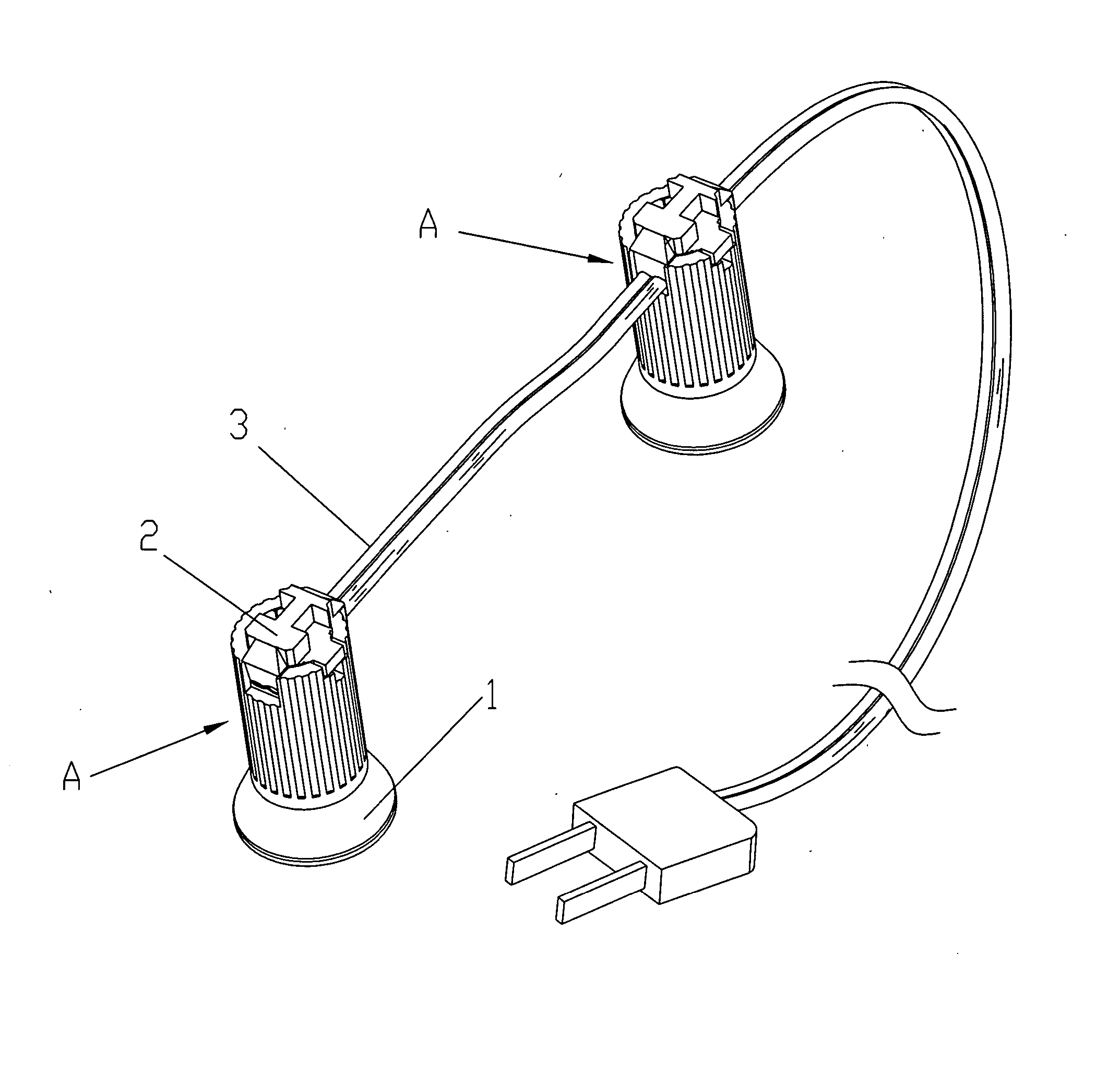

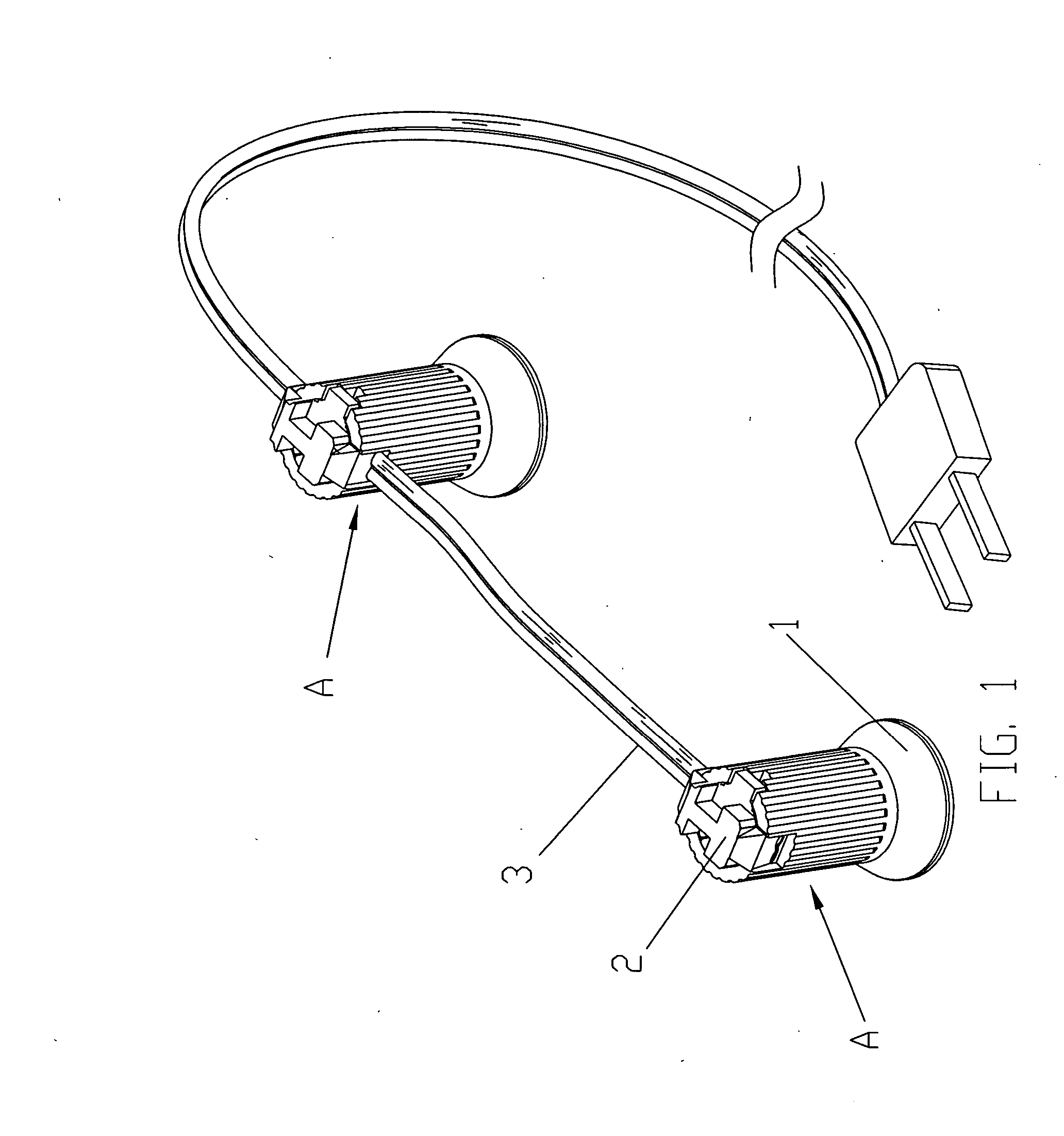

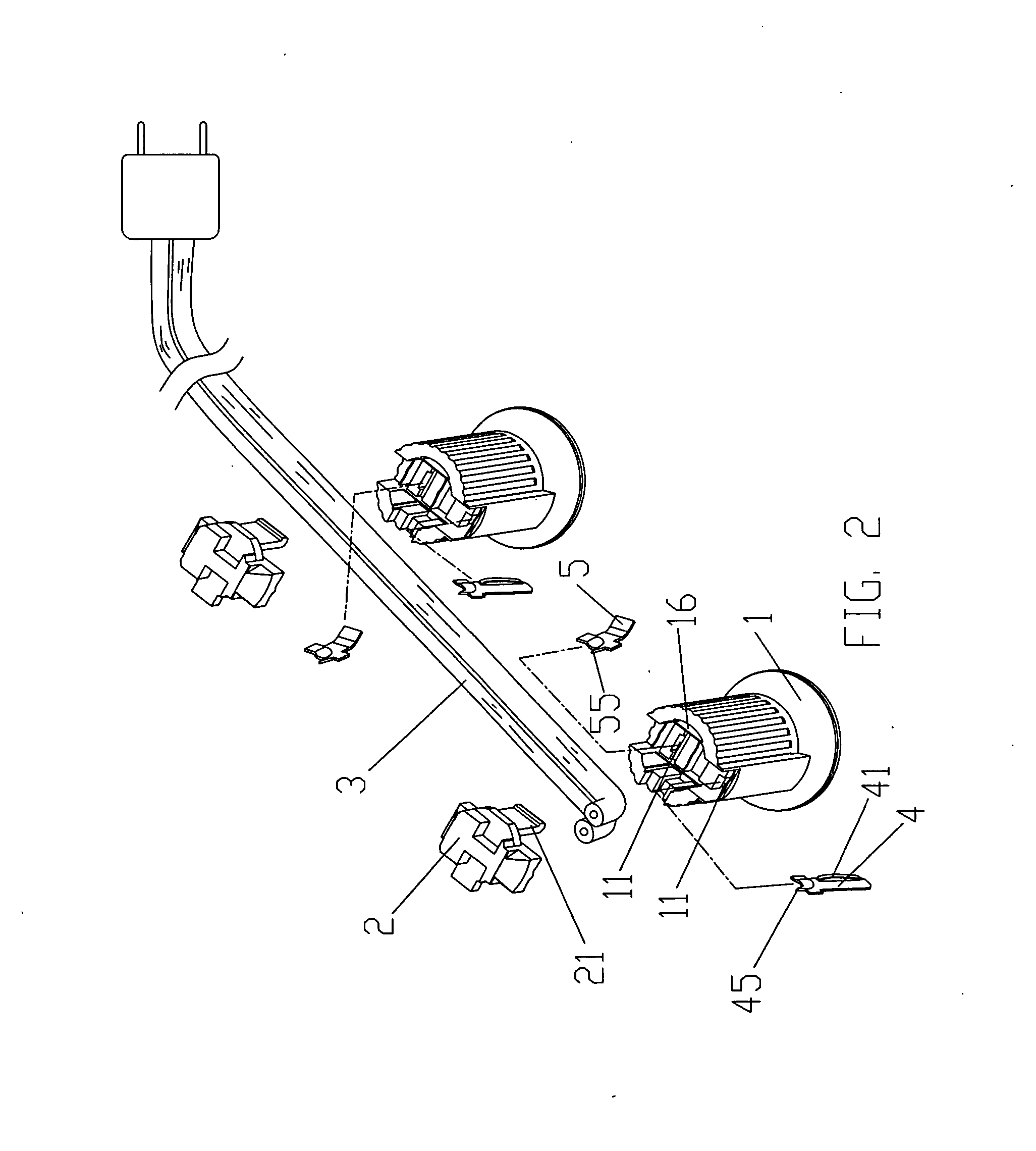

String lamp assembly

InactiveUS20070218753A1Avoid exposureImprove aesthetic qualityCoupling device detailsContact members penetrating/cutting insulation/cable strandsEngineeringElectrical and Electronics engineering

A lamp assembly includes two juxtaposed electric cords, and a plurality of lamps each mounted on the electric cords. Each of the lamps includes a lamp holder, and a lamp cover. The lamp cover has an inside formed with two receiving grooves. Thus, the distal ends of the electric cords are received in the receiving grooves of the lamp cover to prevent the distal ends of the electric cords from being exposed outwardly. In addition, the lamp cover has a periphery formed with a plurality of flattened edges to define a plurality of gaps between the lamp cover and the lamp holder to provide water draining and air ventilating effects.

Owner:TSAI CHIN SUNG

Anthracene derivatives and organic electroluminescent device using same

ActiveUS8395144B2Increase brightnessImprove efficiencyGroup 4/14 element organic compoundsOrganic compound preparationArylAnthracene

Provided are a novel anthracene derivative and an organic light-emitting device using the same, and more particularly, an anthracene derivative having a core (e.g., an indenoanthracene core) where an anthracene moiety with excellent device characteristics is fused with a fluorene moiety or the like with excellent fluorescent properties, wherein an aryl group is introduced at the core, and an organic light-emitting device using the anthracene derivative, which is enhanced in efficiency, operating voltage, lifetime, etc.

Owner:SOLUS ADVANCED MATERIALS CO LTD

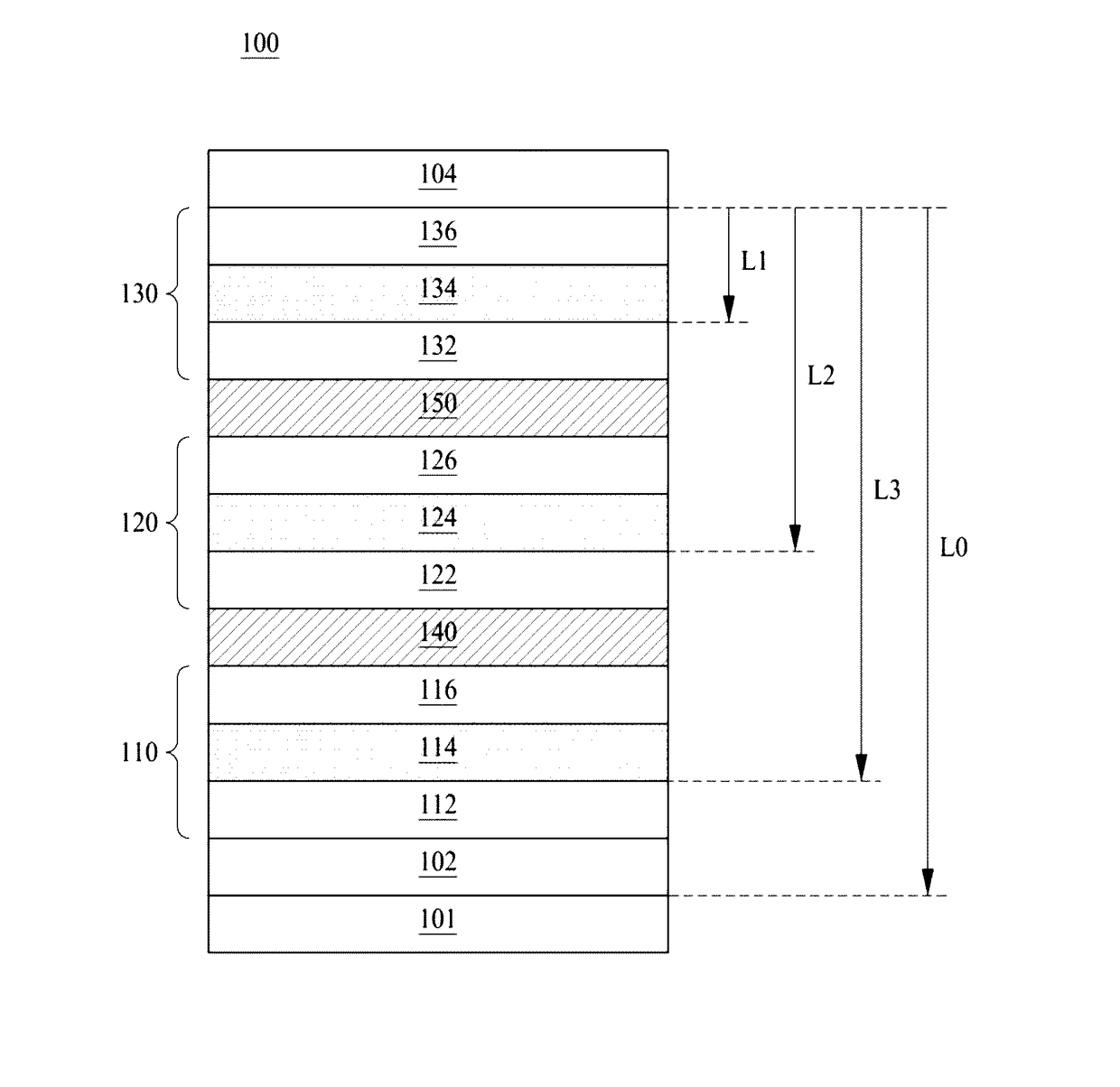

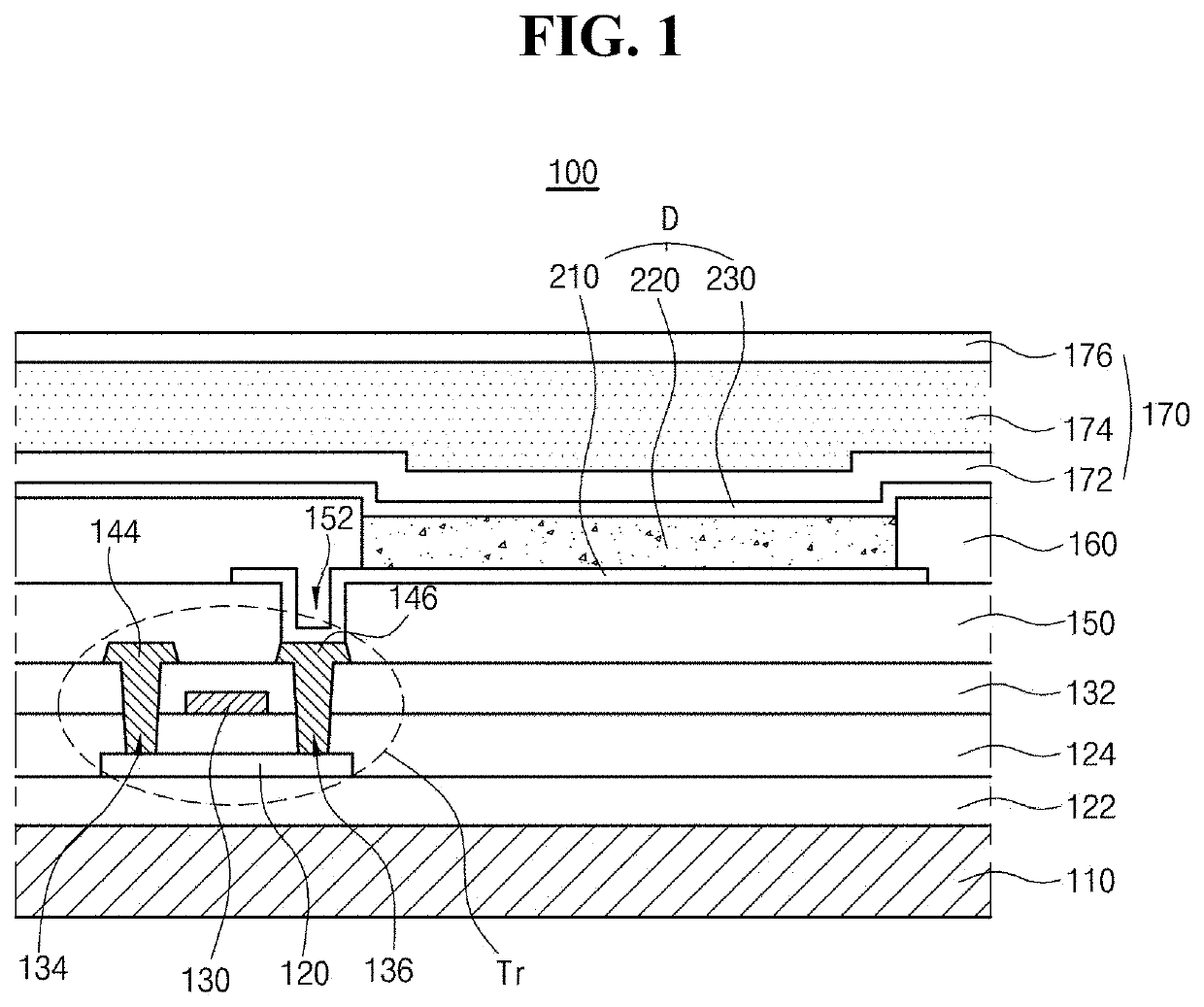

Organic light emitting display device and lighting apparatus for vehicles using the same

ActiveUS9627639B2Improve efficiencyEnhancing lifetimeVehicle headlampsElectroluminescent light sourcesOrganic layerDisplay device

Disclosed are an organic light emitting display device and lighting apparatus for vehicles using the same. The organic light emitting display device includes a first layer including a first organic layer and a first emission layer on a first electrode, a second layer including a second emission layer and a second organic layer on the first layer, a second electrode on the second layer, and a third organic layer between the first layer and the second layer. A thickness of the first emission layer is equal to or greater than a thickness of each of the first organic layer and the second organic layer.

Owner:LG DISPLAY CO LTD

White organic light emitting device

ActiveUS9685622B2Improve efficiencyEnhancing lifetimeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceEmission efficiency

Owner:LG DISPLAY CO LTD

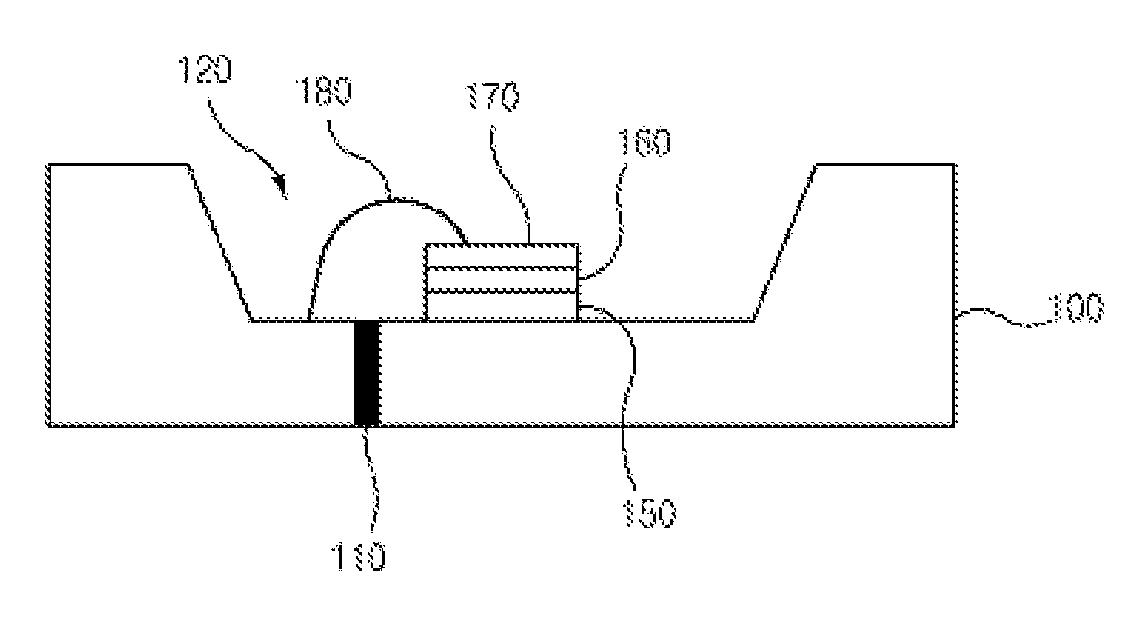

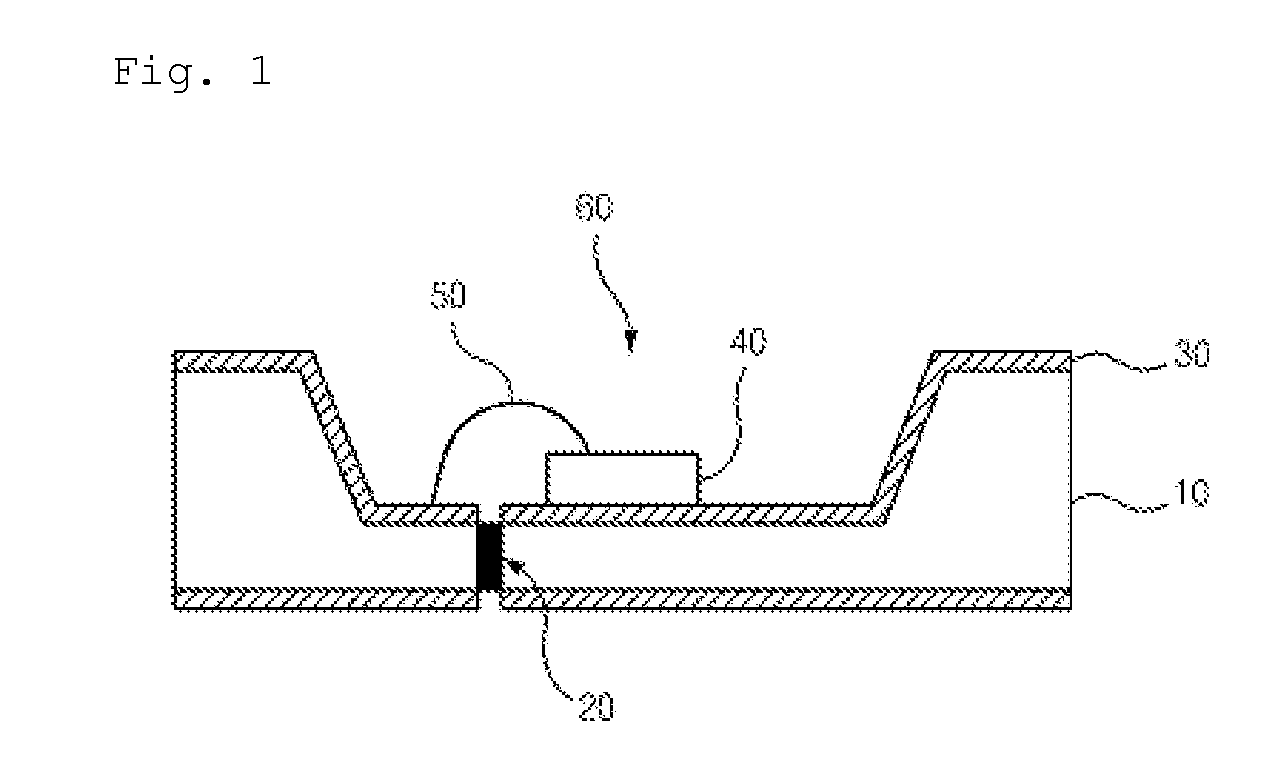

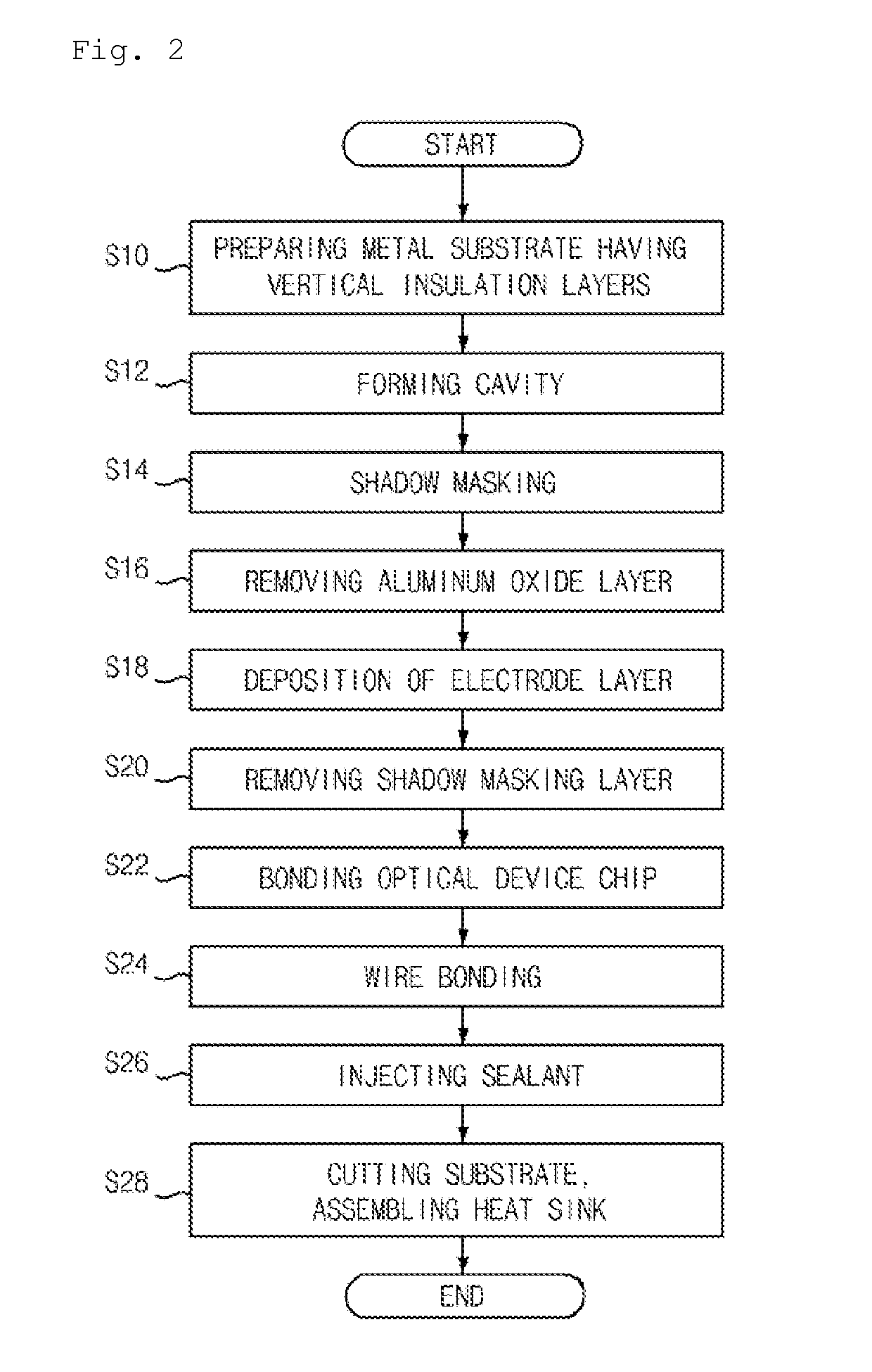

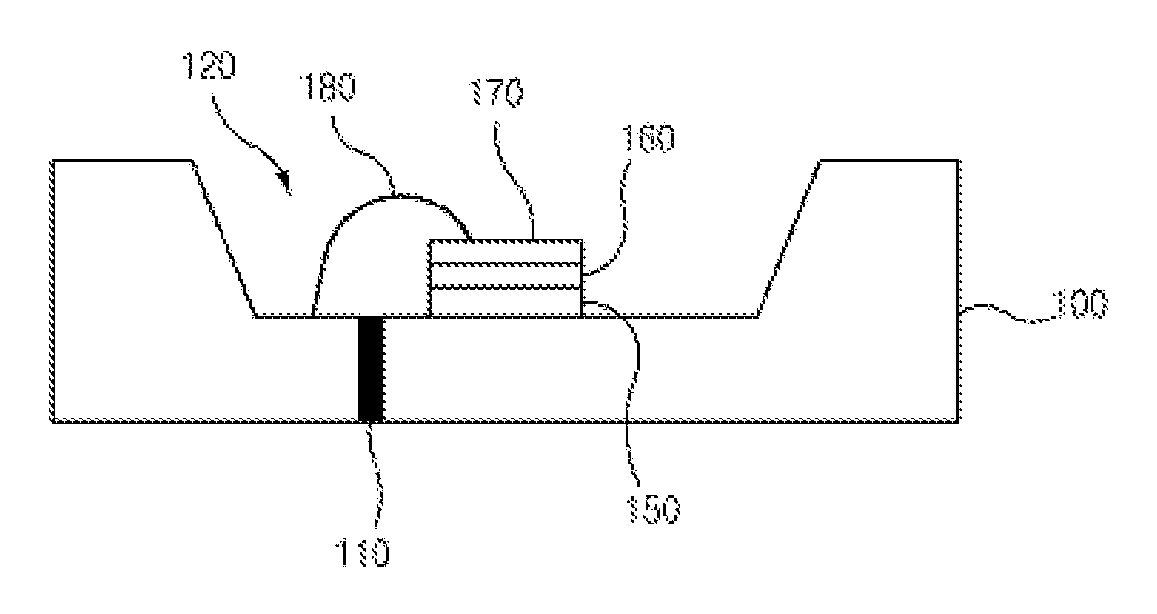

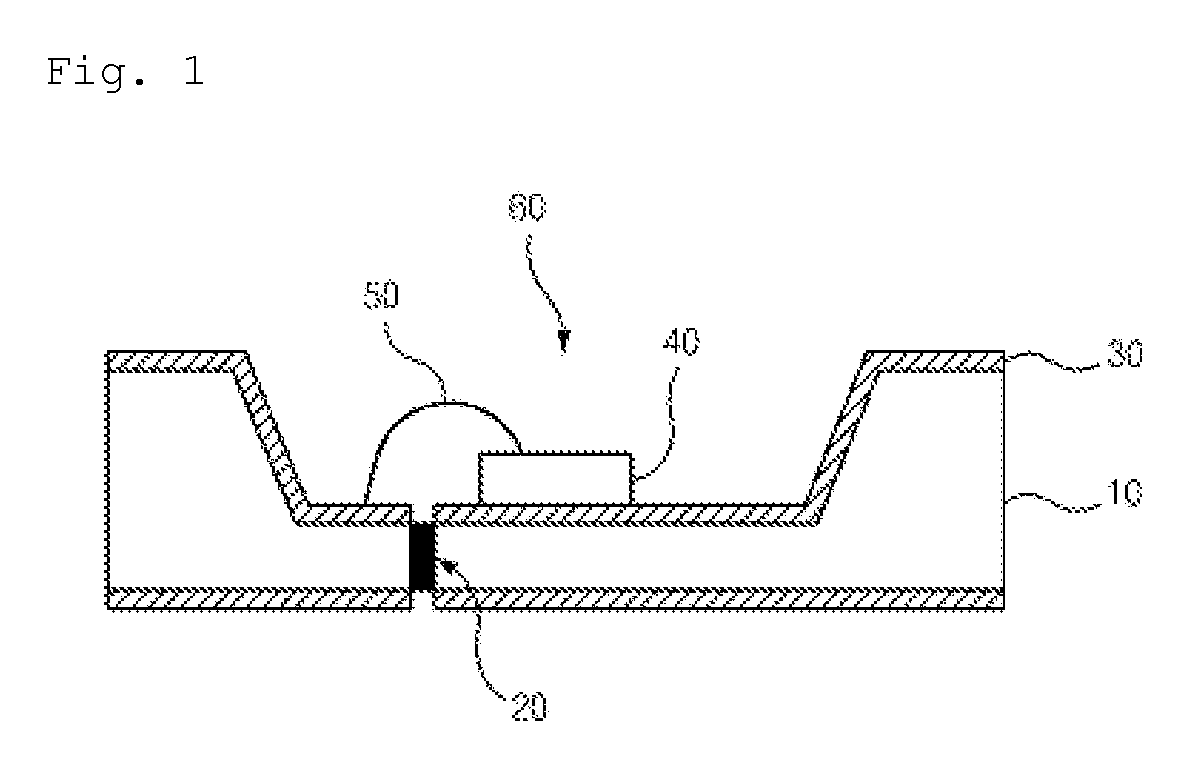

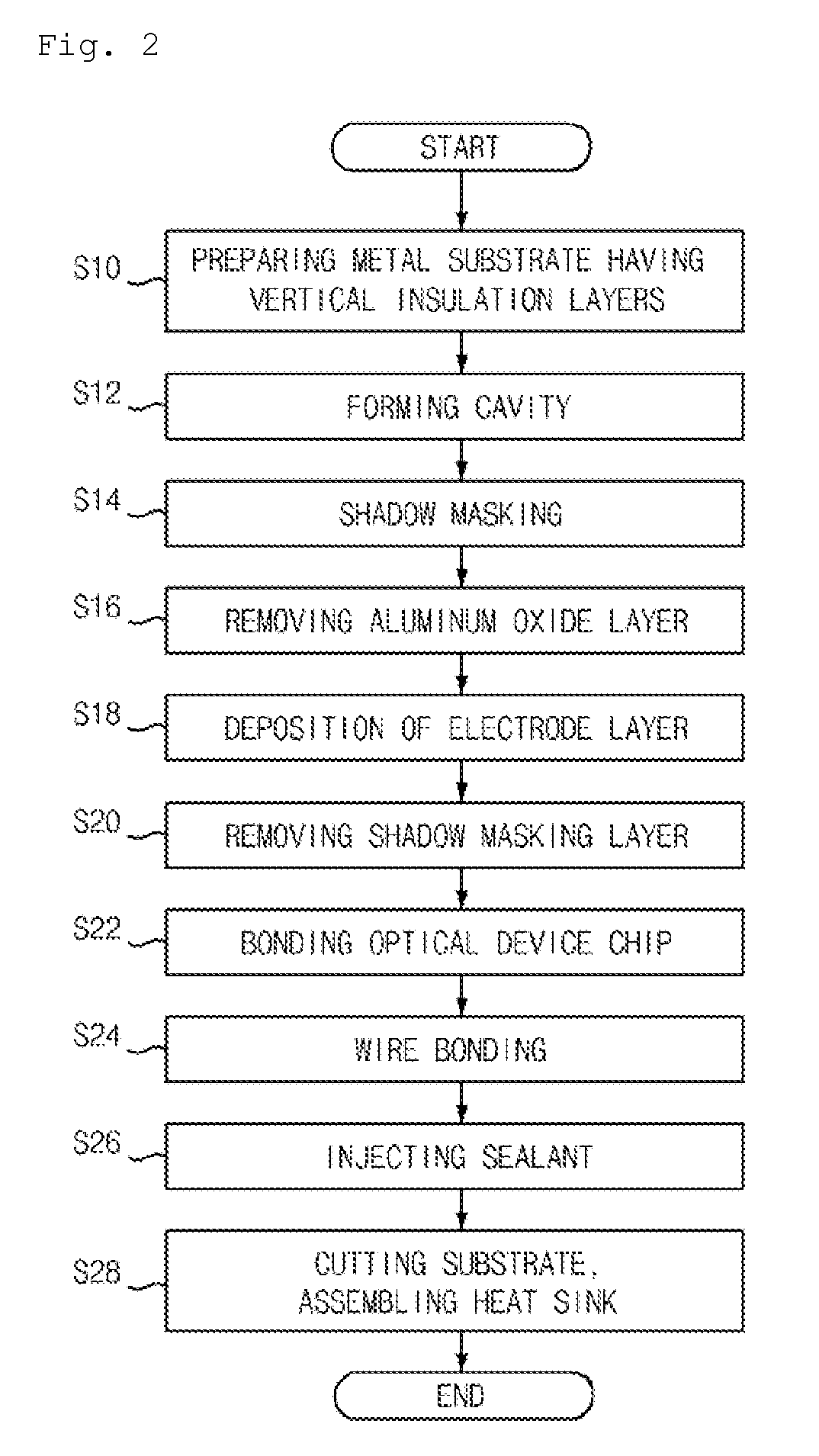

LED metal substrate package and method of manufacturing same

ActiveUS20160190407A1Improve efficiencyEnhancing lifetimeSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyInsulation layer

The present invention relates to an LED metal substrate package, and particularly, to an LED metal substrate package having a heat dissipating structure, and a method of manufacturing same. The method comprises at least the steps of: forming at least one cavity having a groove of a predetermined depth in a metal substrate that is electrically separated by at least one vertical insulation layer, the cavity having one vertical insulation layer built in a floor thereof; treating all surfaces, except portions of the top surface of the metal substrate formed in the respective cavities, with shadow masking; removing an oxide film formed on the surface portions that have not been treated with masking; depositing an electrode layer on each of the surface portions of the oxide layer that have been removed; removing the shadow mask; performing Au / Sn soldering on the electrode layer and bonding an optical device chip; and wire bonding one electrode of the optical device, disposed on one side of the metal substrate with respect to each of the vertical insulation layers, through wires to the metal substrate disposed on the other side of each of the vertical insulation layers. The present invention forms solder using Au / Sn material, which has good heat dissipating characteristics and good bonding characteristics, on the electrode layer to bond an optical device chip, so as to have excellent heat dissipating performance compared to existing LED metal packages that use Ag epoxy.

Owner:POINT ENG

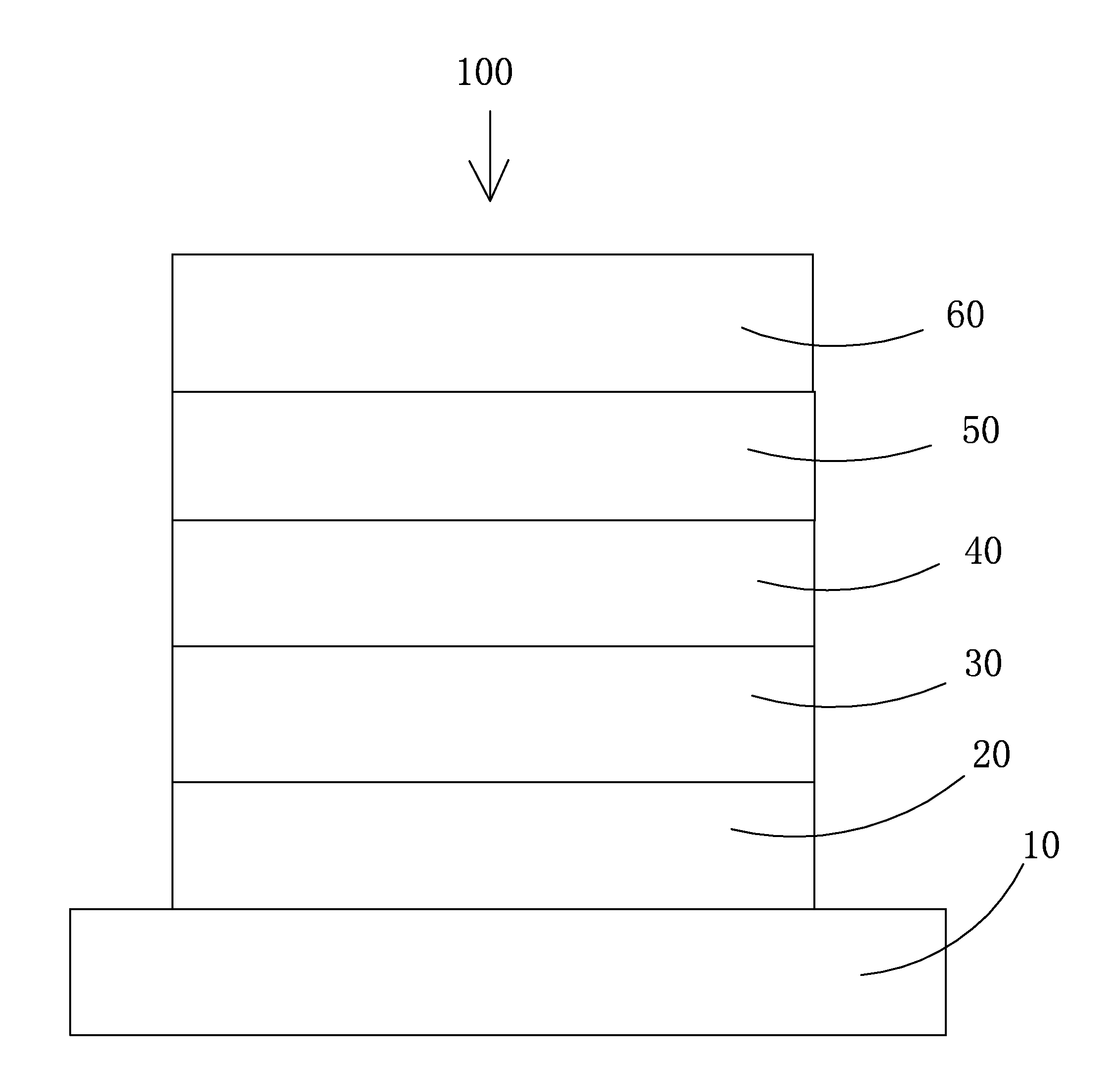

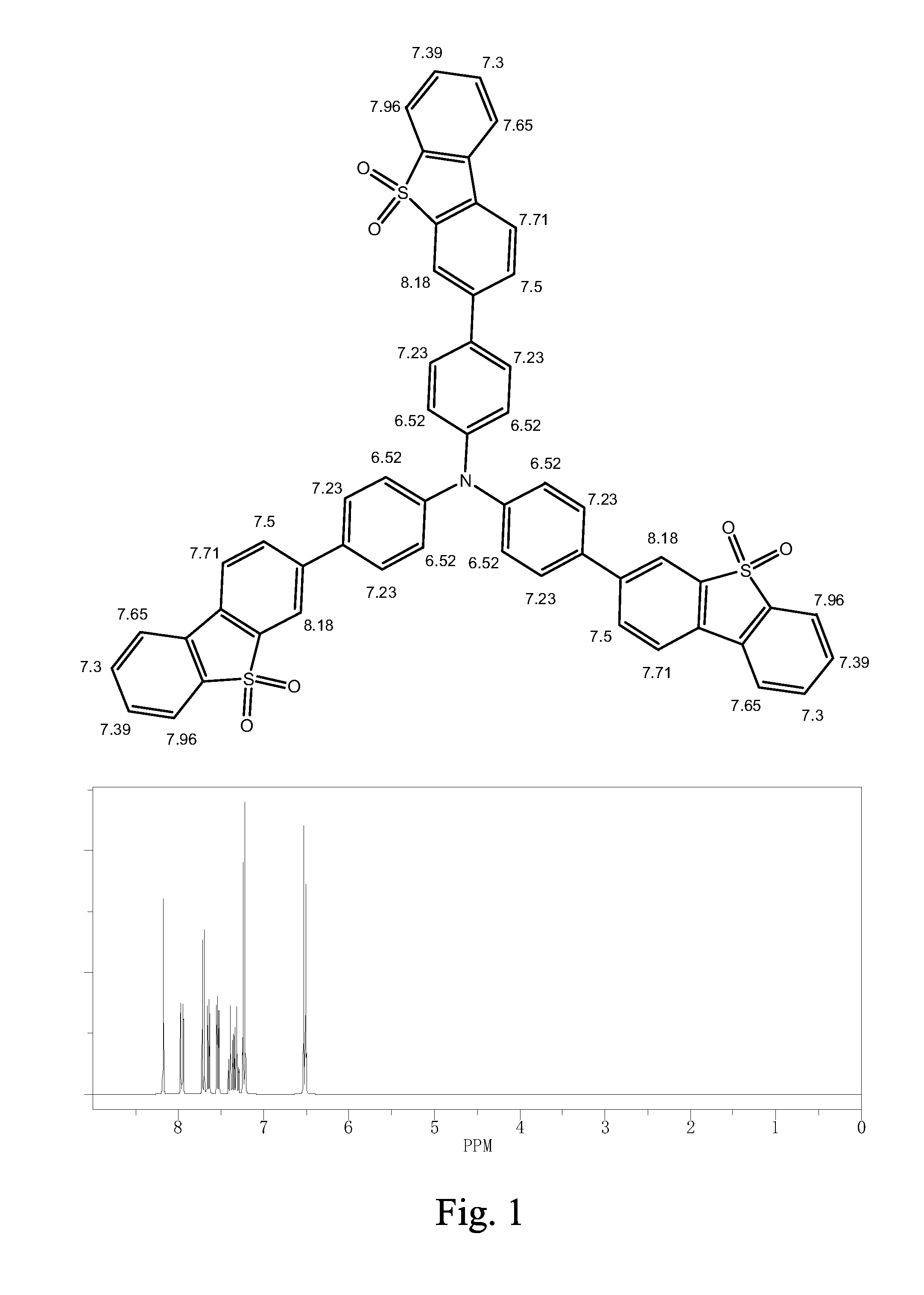

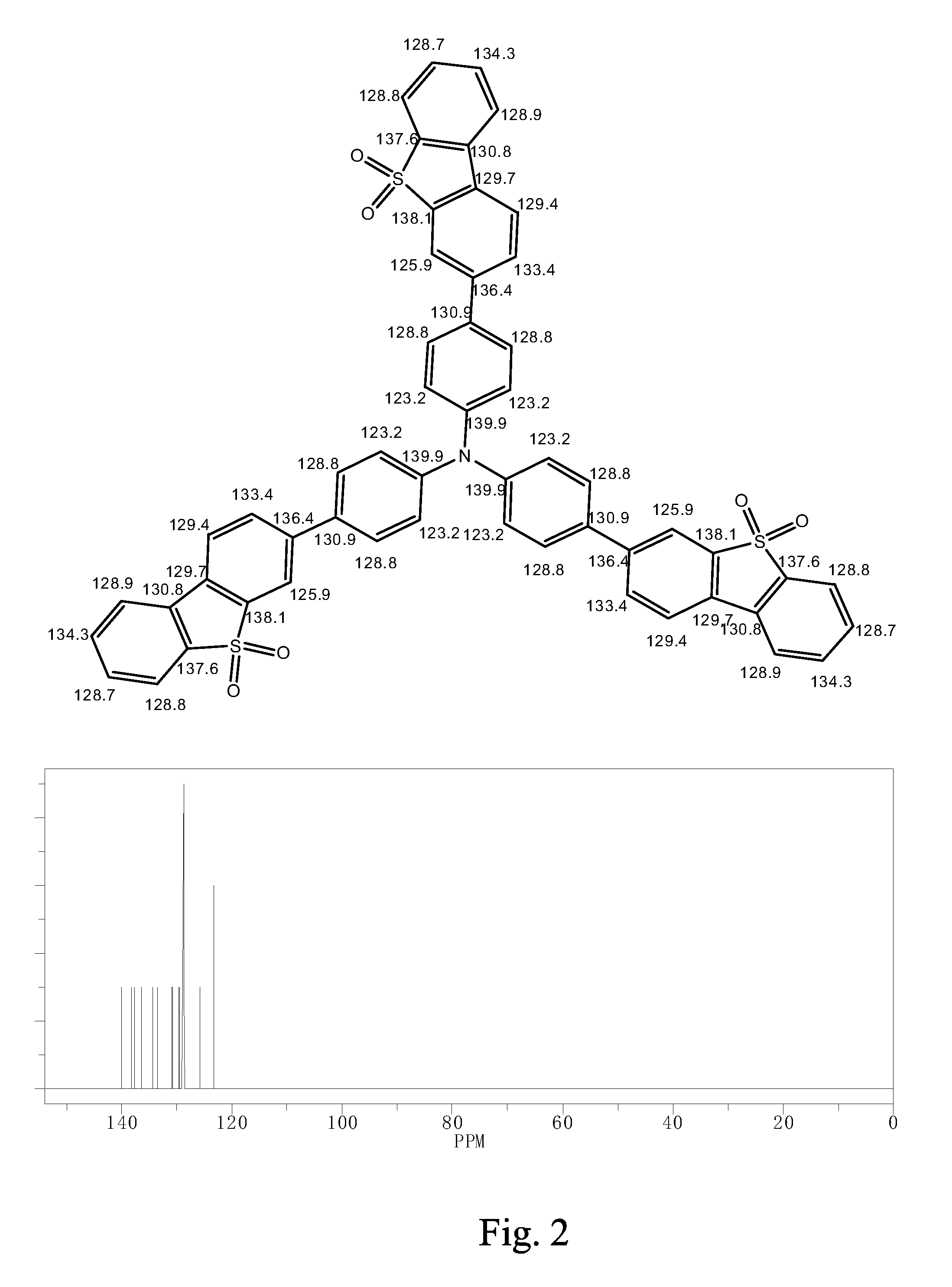

A Sulfone Group-Containing Compound, An Organic Light Emitting Diode (OLED) Device Using The Same, and A Method of Fabricating the OLED Device

ActiveUS20150357584A1Improve efficiencyEnhancing lifetimeSilicon organic compoundsSolid-state devicesSulfoneLight-emitting diode

The present invention provides a sulfone group-containing compound, an organic light emitting diode (OLED) device using the sulfone group-containing compound, and a method of fabricating the OLED device. The sulfone group-containing compound has formula aswherein the bridging unit R is capable of connecting to three or more than three fluorene sulfur oxide units; and the unit R1, R2 and R3 respectively connected to the fluorene sulfur oxide units are selected from alkyl chains, aromatic groups or heterocyclic groups. According to the present invention, the sulfone group-containing compound connects to three or more than three fluorene sulfur oxide units with a bridging unit to form a novel star-shaped molecular structure. The sulfone groups-containing compound combines electron affinity and transport properties of the fluorene sulfur oxide units and spatial characteristics of the star-shaped molecular structure, so that efficiency and lifetime of an OLED device using the same can be enhanced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

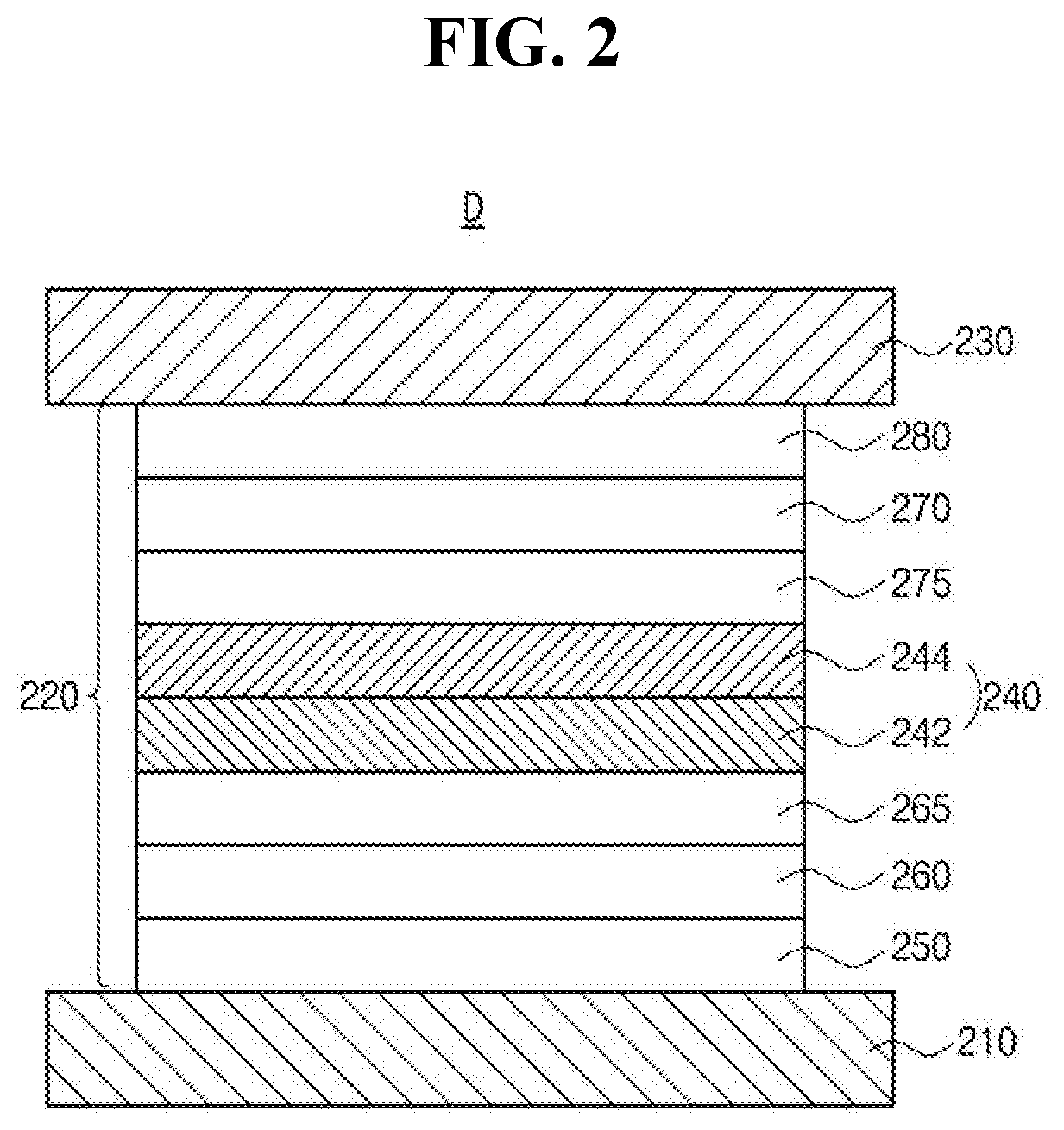

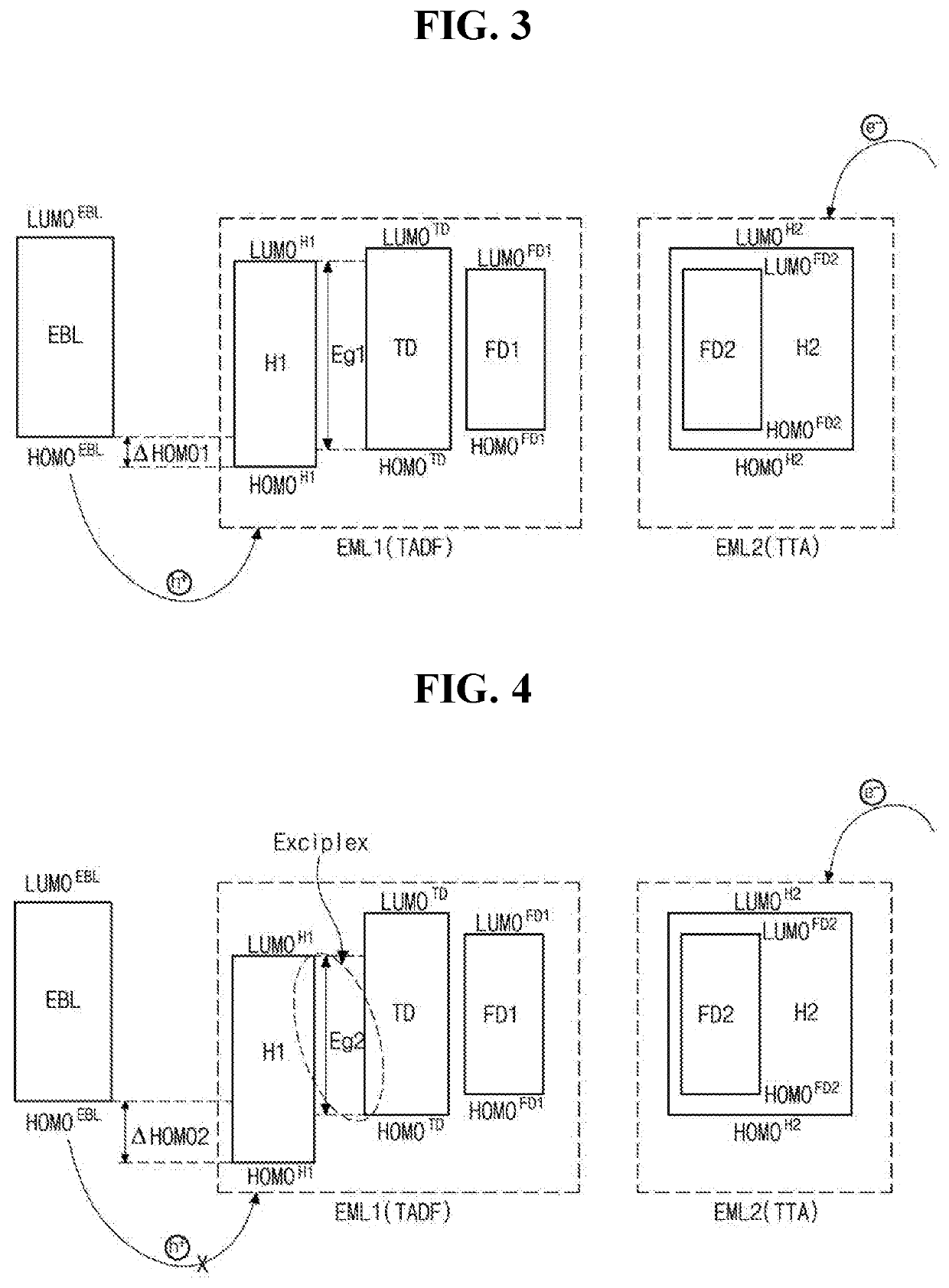

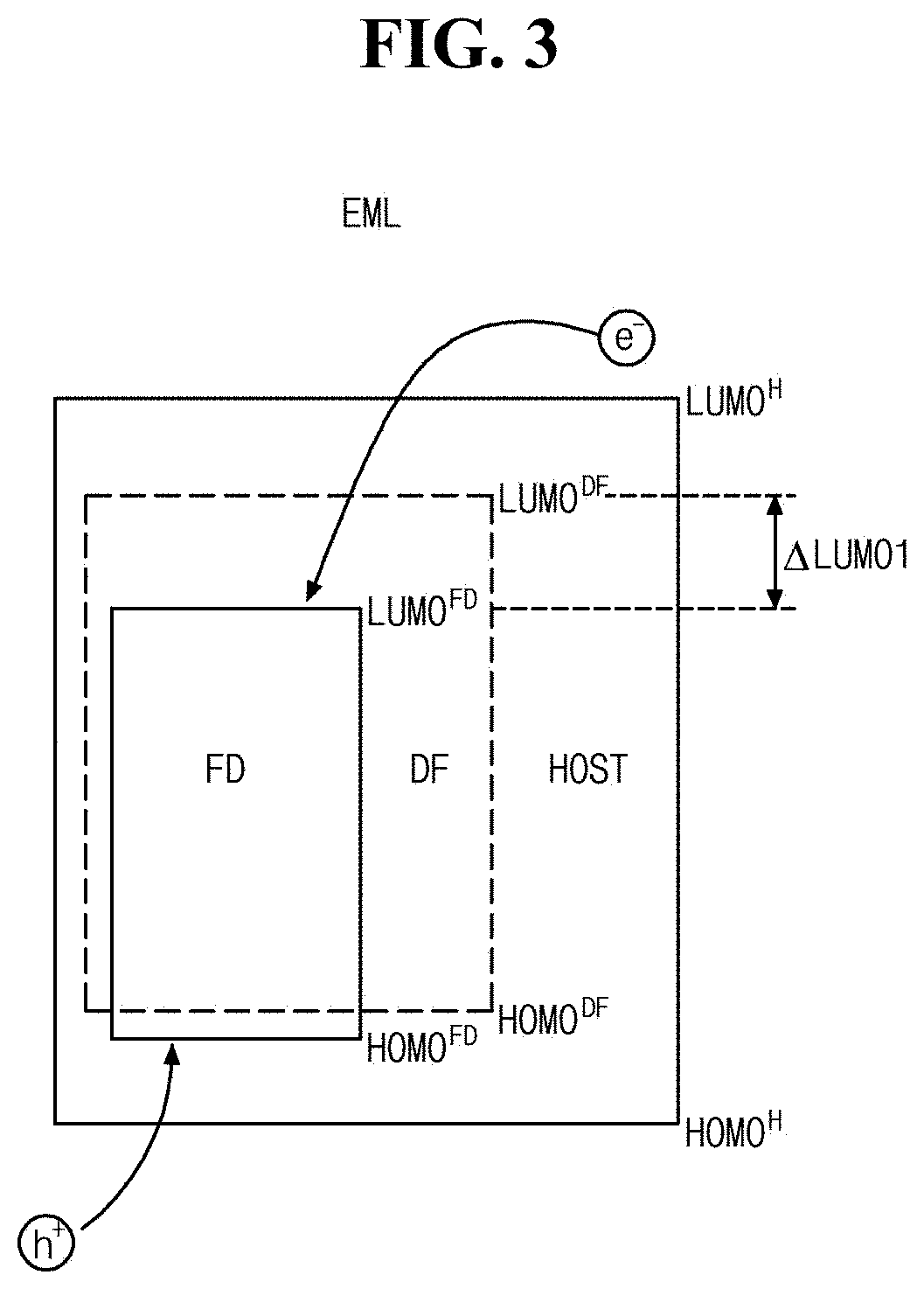

Organic light emitting diode and organic light emitting device including the same

PendingUS20210126205A1Reduce the driving voltageImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron holeOrganic light emitting device

An organic light emitting diode (OLED) includes a first emitting material layer disposed adjacently to a first electrode and a second emitting material layer disposed adjacently to a second electrode. The first emitting material layer includes a first compound having high affinity to holes and a second compound of thermally activated delayed fluorescent material, and the second emitting material layer includes a fourth compound having high affinity to electrons and implementing triplet-triplet annihilation. Two emitting material layers having adjusted energy levels allow the OLED to lower its driving voltages and improve its luminous efficiency and luminous lifetime.

Owner:LG DISPLAY CO LTD

Organic light emitting device having an optical distance of a micro cavity and method of fabricating the same

ActiveUS10211417B2Quality improvementIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingBlue emissionOrganic light emitting device

Owner:LG DISPLAY CO LTD

LED metal substrate package and method of manufacturing same

ActiveUS9559276B2Improve efficiencyEnhancing lifetimeSolid-state devicesSemiconductor devicesEpoxyInsulation layer

Owner:POINT ENG

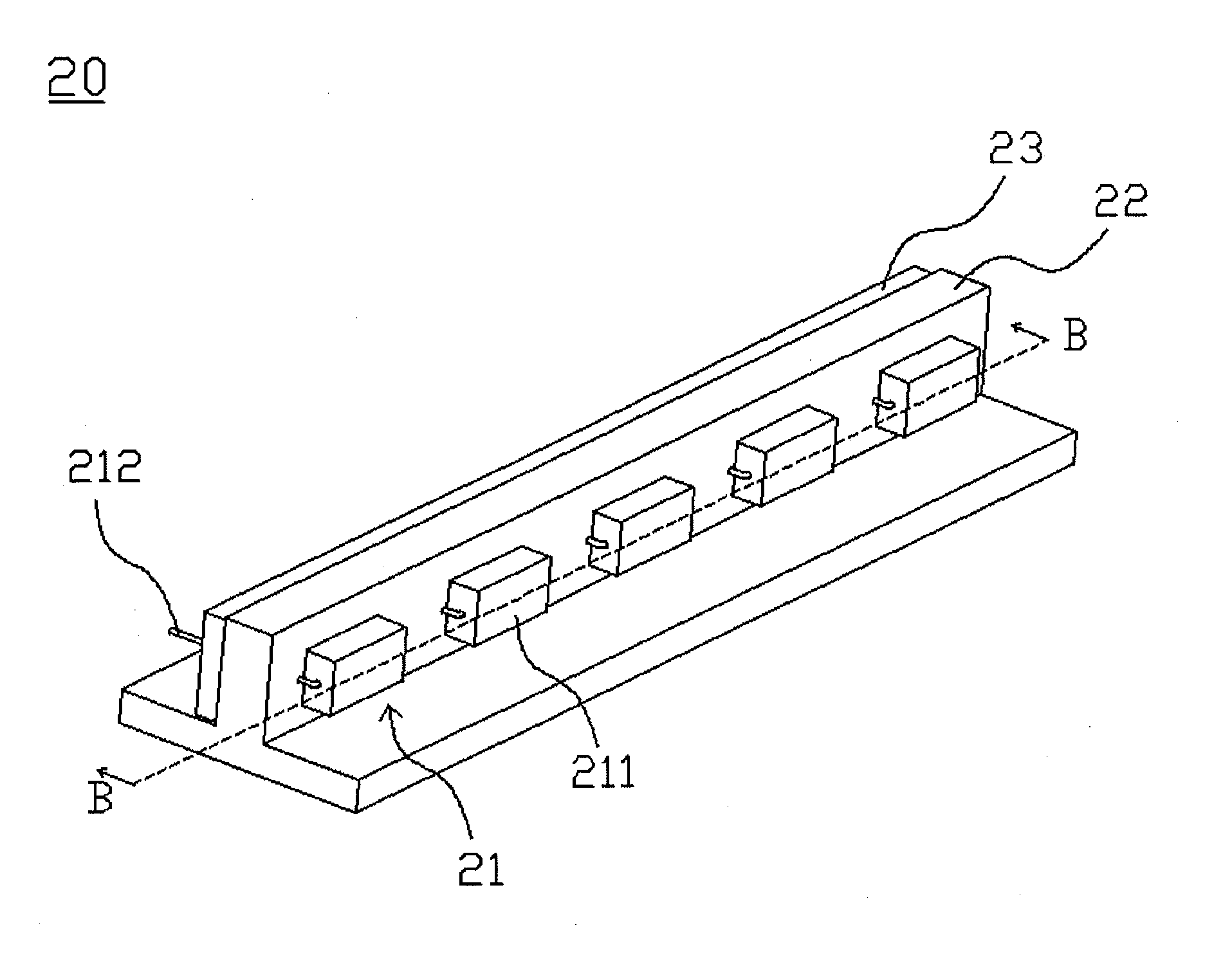

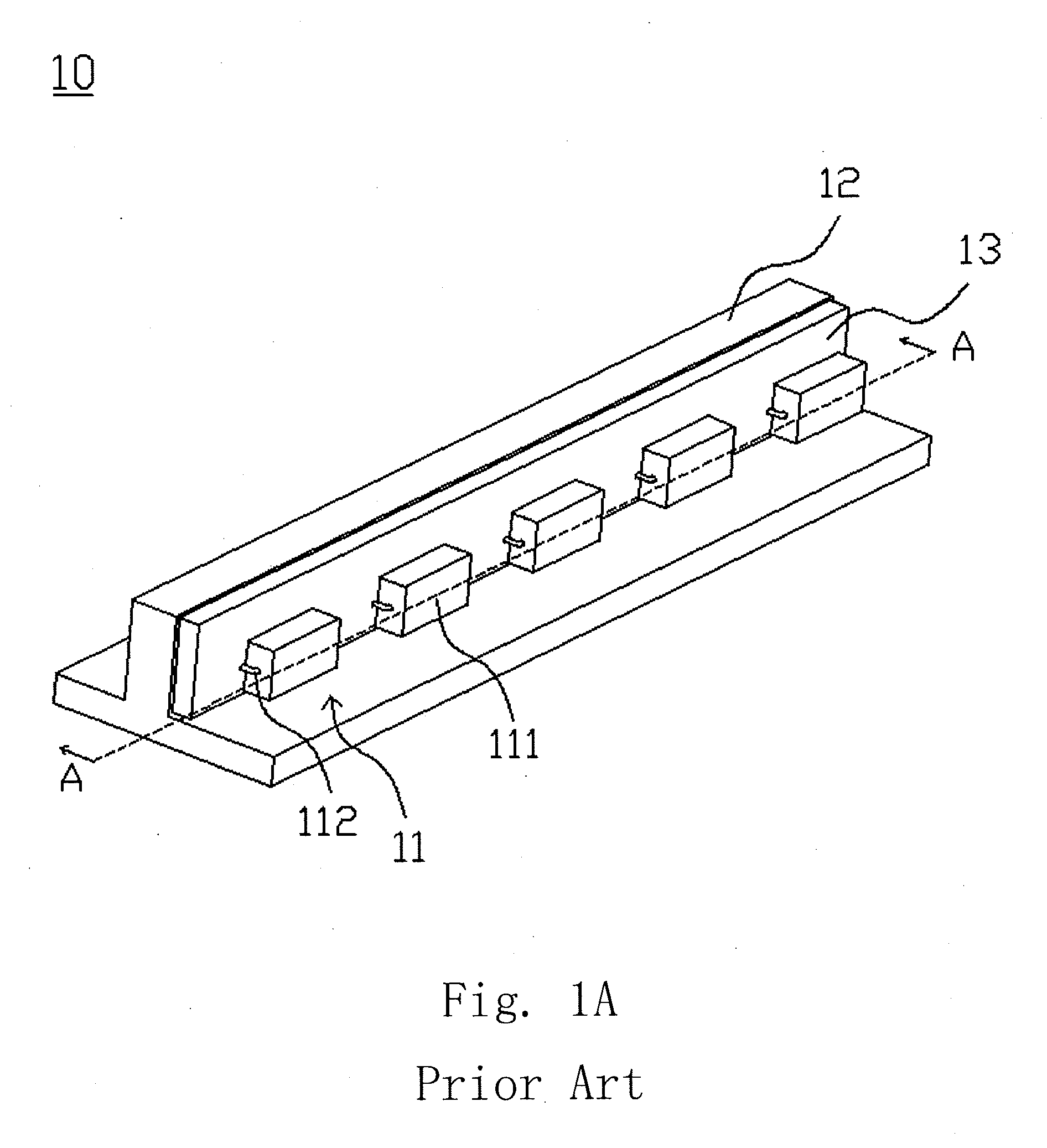

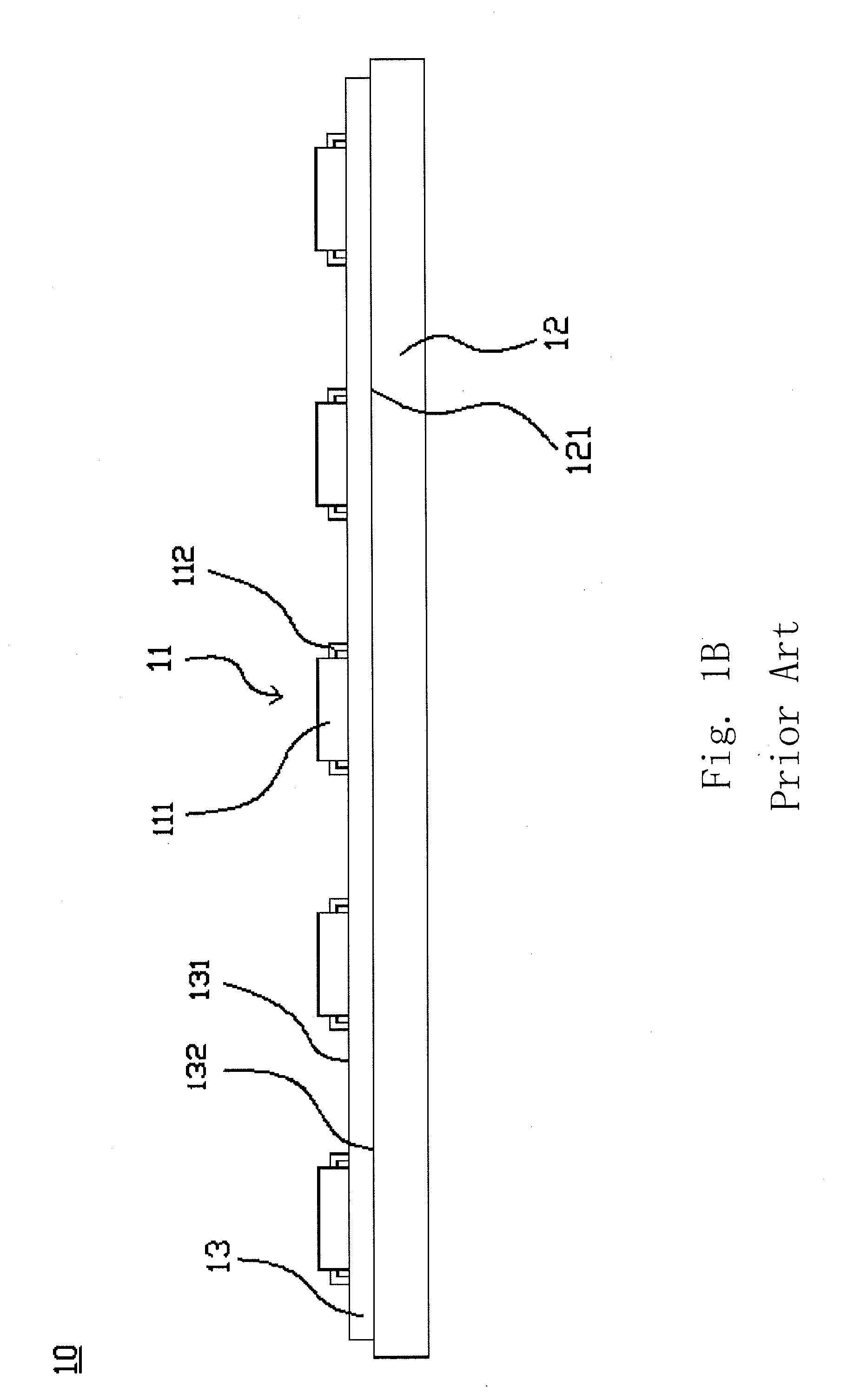

Light source heat-dissipation structure of backlight module

InactiveUS20120250288A1Improve efficiencyEnhancing lifetimeLighting heating/cooling arrangementsIlluminated signsEngineeringSupport surface

The present invention provides a light source heat-dissipation structure of a backlight module having: a light-source structure, the heat-dissipation base and a carrier. The light-source structure has leads, respectively. The heat-dissipation base has a supporting surface, an attachment surface and first through holes. The carrier has second through holes, and the carrier is attached to the attachment surface of the heat-dissipation base. The light-source structure is set on the supporting surface of the heat-dissipation base, and the leads of the light-source structure pass through the first through holes and the second through holes and then electrically connect with the carrier. Hence, the heat-dissipation base may directly support and thermally contact the light-source structure for relatively enhancing the heat-dissipation efficiency of the light-source structure.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Organic light emitting diode and organic light emitting device having thereof

PendingUS20210280792A1Improve luminous performanceImproved light emissionSolid-state devicesSemiconductor/solid-state device manufacturingAnthraceneDopant

The present disclosure relates to an organic light emitting diode that includes at least one emitting material layer including an anthracene-based host and a boron-based dopant, at least one electron blocking layer including an amine-based compound substituted with at least one polycyclic aryl group, and optionally at least one hole blocking layer including an azine-based compound or a benzimidazole-based compound. The organic light emitting diode has enhanced luminous efficiency as well as excellent luminous lifetime.

Owner:LG DISPLAY CO LTD

Organic light emitting diode and organic light emitting device including the same

PendingUS20210119140A1Reduce the driving voltageImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingOrganic light emitting deviceTriazine

An organic light emitting diode (OLED) including at least one emitting material layer (EML) disposed two electrodes and comprising triazine-based delayed fluorescent material and boron-dipyrromethene-based fluorescent material and an organic light emitting device including the OLED is disclosed. The triazine-based delayed fluorescent material and the boron-dipyrromethene-based fluorescent material may be included in an identical EML or in adjacently disposed EMLs. The OLED can lower its driving voltage and improve its luminous efficiency by adjusting energy levels of the delayed fluorescent material and the fluorescent material.

Owner:LG DISPLAY CO LTD

Organic light emitting display device (OLED) having p-type charge generation layer (CGL) formed between emissions stack

ActiveUS10950812B2Increase the driving voltageLow efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron holeDisplay device

Discussed is an organic light emitting display device. The organic light emitting display device can include a first emission part, a second emission part on the first emission part, and a first P-type charge generation layer between the first emission part and the second emission part. The first emission part includes a first hole transport layer, a first emission layer, and a first electron transport layer. The second emission part includes a second hole transport layer, a second emission layer, and a second electron transport layer. The second hole transport layer and the first P-type charge generation layer are disposed adjacent to each other. The second hole transport layer includes a first material and a second material. The first material has an absolute value of a HOMO energy level which can be greater than an absolute value of a LUMO energy level of the first P-type charge generation layer.

Owner:LG DISPLAY CO LTD

Organic light emitting diode and organic light emitting device having thereof

PendingUS20220020929A1Improve luminous performanceImproved light emissionSolid-state devicesSemiconductor/solid-state device manufacturingAnthraceneDopant

The present disclosure relates to an organic light emitting diode that includes at least one emitting material layer including an anthracene-based host and a boron-based dopant, at least one electron blocking layer including an amine-based compound substituted with at least one fused aromatic or hetero aromatic ring, and optionally at least one hole blocking layer including an azine-based compound or a benzimidazole-based compound. The organic light emitting diode has enhanced luminous efficiency as well as excellent luminous lifetime.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com