Gas-liquid-solid three-phase separation system

A three-phase separation, gas-liquid-solid technology, applied in the field of multi-phase separation, can solve the problems of lack of separation methods, etc., and achieve the effects of reducing corrosion, stable and efficient system integration, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

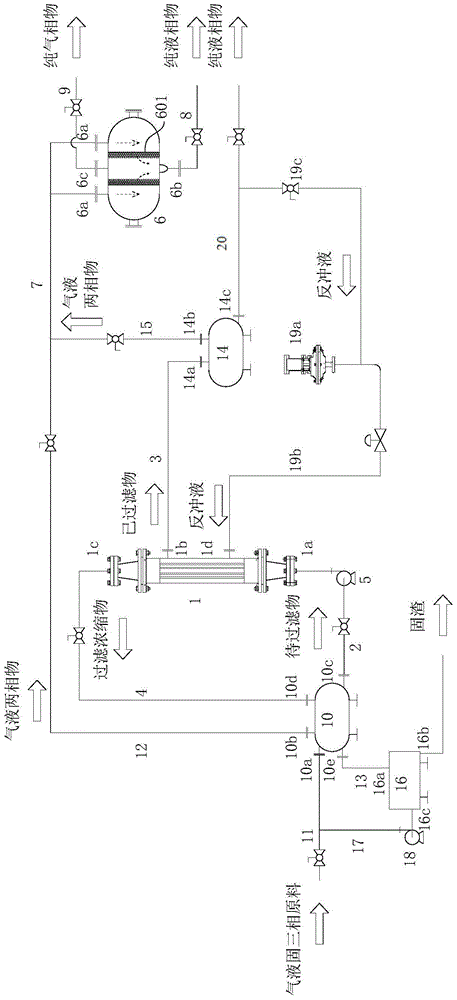

[0009] Such as figure 1 The gas-liquid-solid three-phase separation system shown includes:

[0010] Cross-flow filter 1, the cross-flow filter 1 has a filter input port 1a, a filtered product output port 1b, a filter concentrate output port 1c and a backflush liquid input port 1d, and the filter input port 1a is connected to The output end of the to-be-filtered material delivery pipe 2, the filtered material output port 1b is connected to the input end of the filtered material delivery pipe 3, the filtered concentrate output port 1c is connected to the input end of the concentrated product return pipe 4, and the backflush liquid input port 1d is connected to The recoil device, the feed pump 5 is arranged on the conveying pipe 2 of the material to be filtered;

[0011] A gas-liquid coalescer 6, the gas-liquid coalescer 6 has a gas-liquid two-phase material input port 6a, a high-purity liquid phase material output port 6b and a high-purity gas-phase material output port 6c, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com