Automatic dustproof system and method for separation chamber

A sorting room and dust-proof technology, which is applied in the field of color sorters, can solve the problems of sealing strips reducing the sealing effect, affecting the working effect of the color sorter, and affecting the quality of the original signal, so as to increase the cost of after-sales maintenance, with great results and low cost. increase the effect of low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

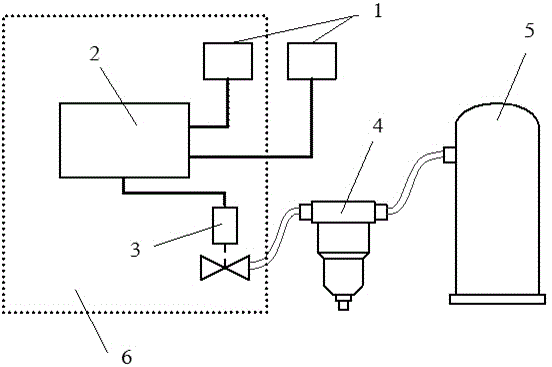

[0020] exist figure 1 In the schematic block diagram of the system shown, two air pressure sensors 1 are respectively installed inside and outside the chamber 6 of the color sorter, and both air pressure sensors 1 are connected to the control module 2. The air source switch adopts the electromagnetic spray valve 3, and the electromagnetic spray valve 3 is located in the cavity of the sorting chamber 6 of the color sorter. Of course, those skilled in the art know that the gas source switch can also choose other switches. The control module 2 is connected to the electromagnetic spray valve 3, and the electromagnetic spray valve 3 is connected to the The high-pressure gas storage tank 5, in this embodiment, as a preferred solution, a filter 4 is also arranged on the pipeline between the electromagnetic spray valve 3 and the high-pressure gas storage tank 5.

[0021] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com