Reverse boring cutter

A technology of back-boring cutters and tool holders, which is applied in the direction of boring heads, accessories of tool holders, and tools used in lathes, etc., which can solve the problems of high manufacturing cost, low durability, and complex structure of back-boring cutters, and reduce energy consumption. Consumption, saving resources, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and embodiments, and the technical problems and beneficial effects solved by the technical solutions of the present invention will also be described. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention, and It does not have any limiting effect on it.

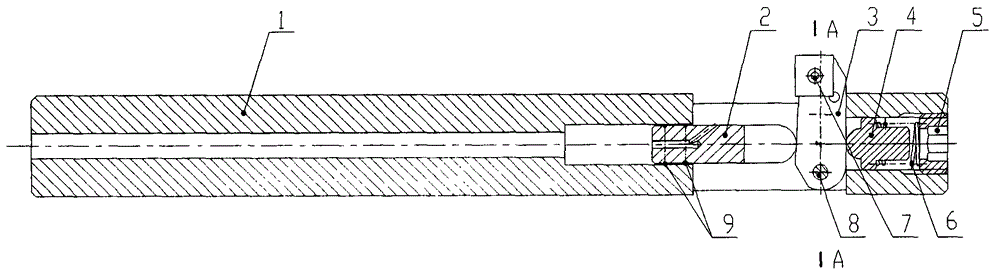

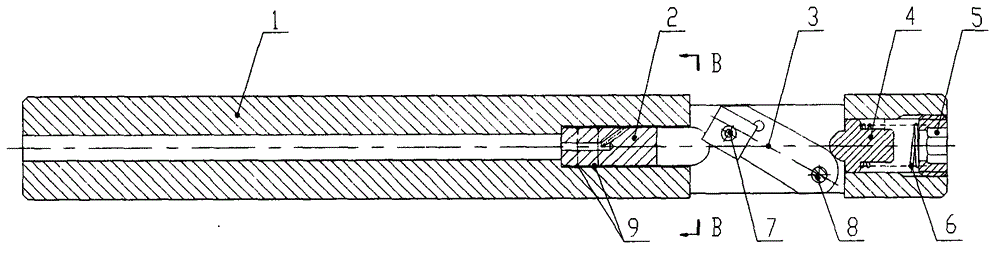

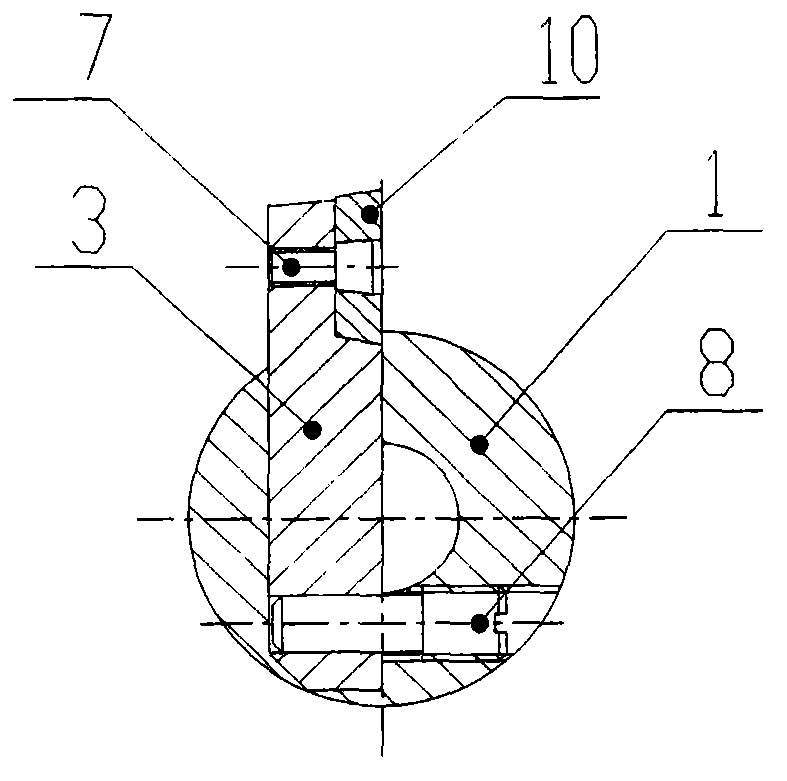

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, it is an example of an anti-boring tool based on the content of the present invention, including a tool holder 1, a slide valve 2, a tool holder 3, a ejector rod 4, a plug cover 5, a spring 6, a compression screw 7, a pin 8, O-ring 9, blade 10, positioning screw 11, a high-pressure coolant through hole 101 is provided at the tail of the cutter bar 1; The body is provided with a hole 106 for installing the positioning screw 11 ; the head is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com