Completed surface part clamping installation device

A technology of complex profiles and installation devices, applied in positioning devices, attachment devices, metal processing machinery parts, etc., to achieve the effect of reasonable structural design, fast production speed, and firm product fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

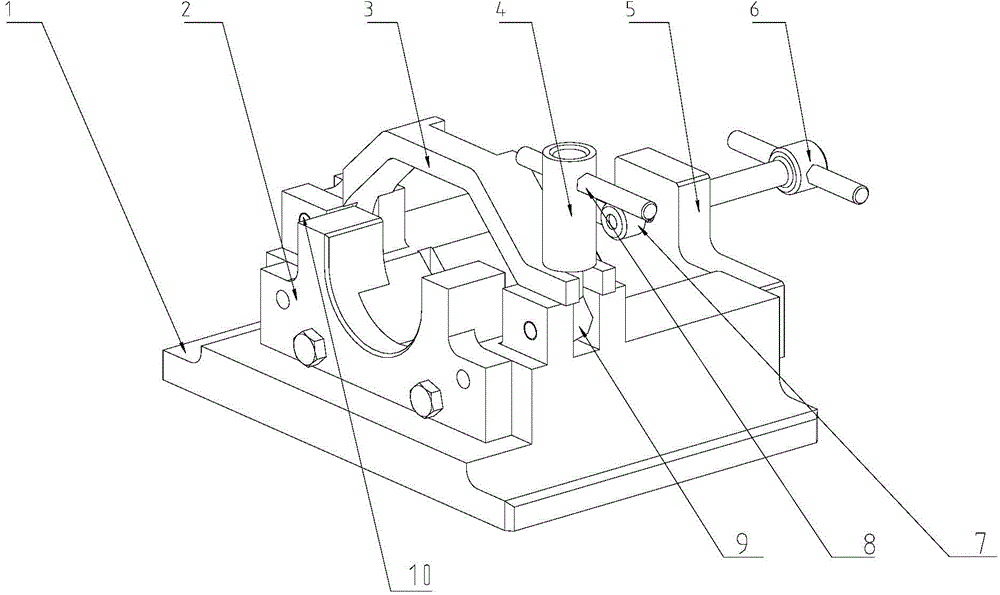

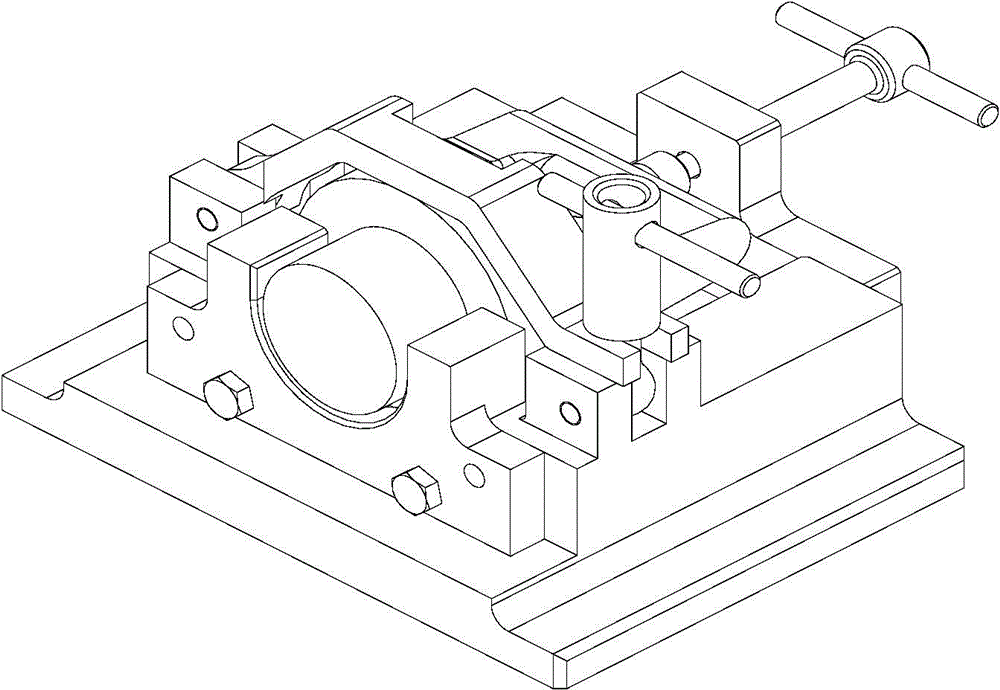

[0018] Such as figure 1 As shown, the clamping installation device for complex profile parts described in the embodiment of the present invention includes a base 1, a positioning plate 2, a pressure plate 3, a compression sleeve 4, a top plate 5, a fixed handle compression screw 6, and a smooth pressure block 7, driving lever 8, swing bolt 9, bearing pin 10.

[0019] The base 1 is the basic installation frame of the tooling, which adopts a V-shaped block structure, which limits the four degrees of freedom of the parts. The positioning plate 2 is fixed on the front end of the base 1 by screws for the axial positioning of the parts; one end of the pressure plate 3 It is movably connected to the card slot on one side of the base 1, and the other end of the pressure plate 3 is adjustable and fixed on the card slot on the other side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com