Paper automatic-arrangement and bookbinding device

An automatic sorting and paper technology, applied in binding, thin material handling, transportation and packaging, etc., can solve the problems of business time waste, low automation level, etc., to achieve the effect of less space occupation, high degree of automation, and enhanced competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

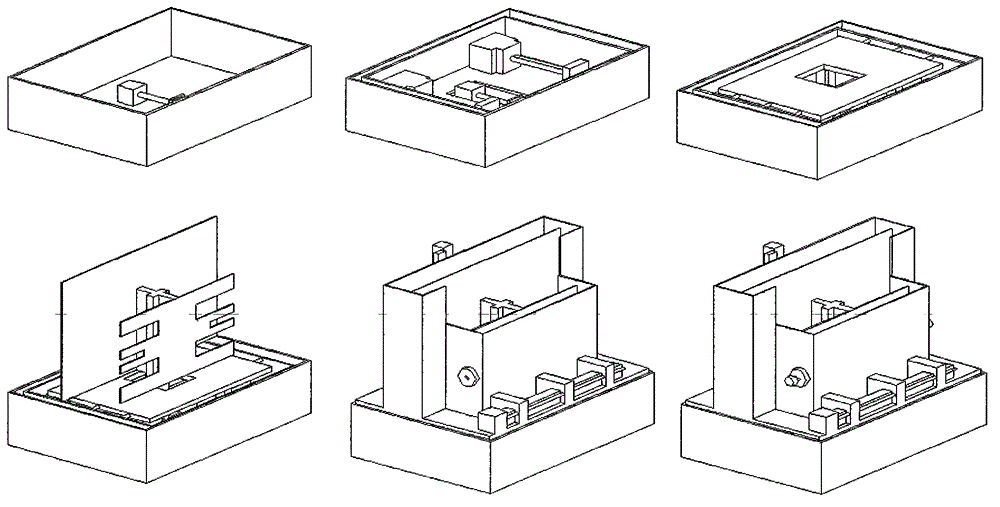

[0038] The present invention is further described now in conjunction with accompanying drawing:

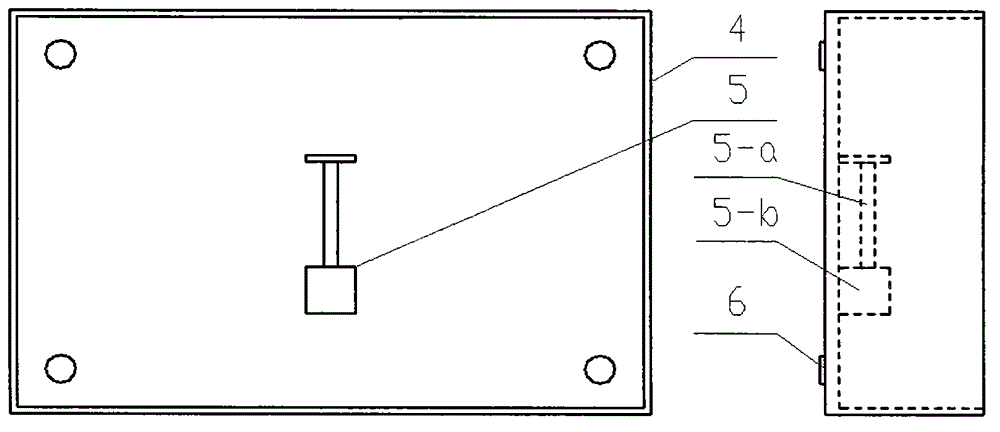

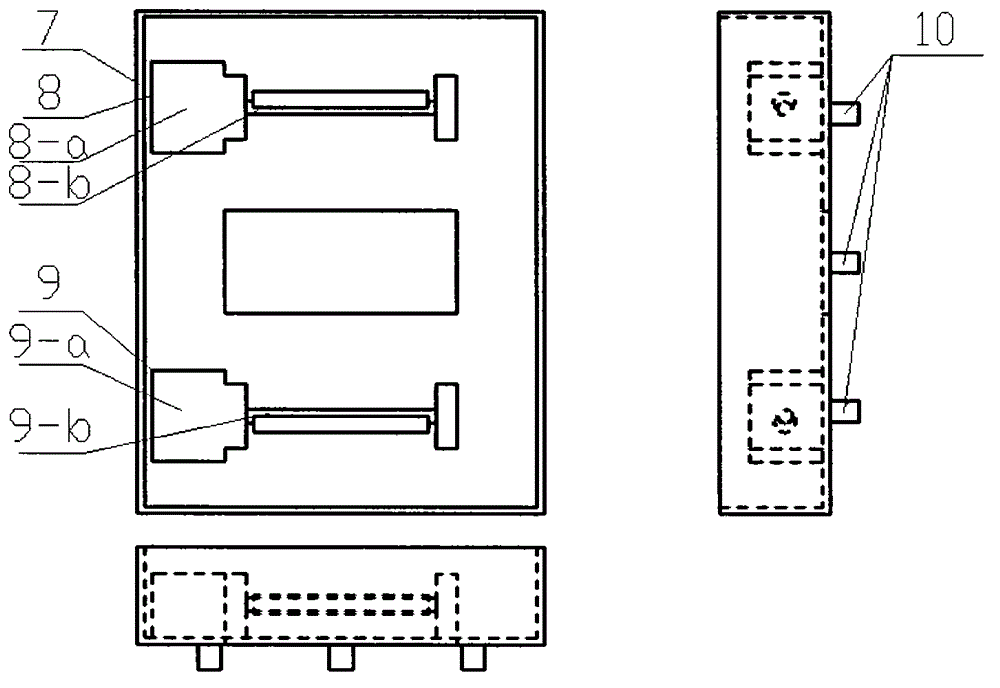

[0039] An automatic paper sorting and binding device, comprising a positioning shell 1, a saddle stitching realization device 2, a flat stitching realization device 3, a base 4, a straight stroke realization device 5, a shock absorbing pad 6, a vertical vibration table 7, and a vertical vibration realization device 1 8. Vertical vibration realization device 2 9. Vertical spring support 10, horizontal vibration table 11, horizontal vibration realization device 1 12, horizontal vibration realization device 2 13, horizontal spring support 14, front and rear movable limit plate 15, left and right adjustable limit plate The bit plate 16 etc. is characterized in that the shock-absorbing gasket 6 is installed on the bottom of the base 4, and the straight stroke realizing device 5 is fixedly installed at the center of the base, and the vertical vibrating table 7 is connected on the base 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com