A compound cutting device for sample-preparing dumbbell pieces

A dumbbell sheet and composite technology, applied in metal processing and other directions, can solve problems such as danger, complicated operation, scratches, etc., and achieve the effects of low cost, simple sample preparation operation, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

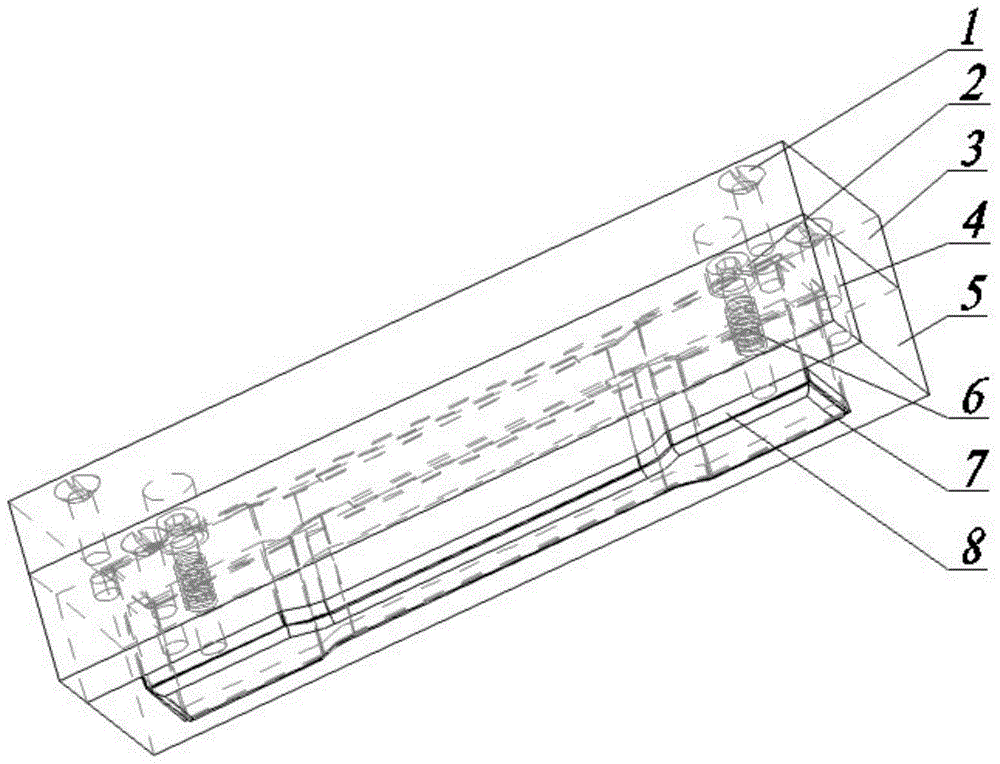

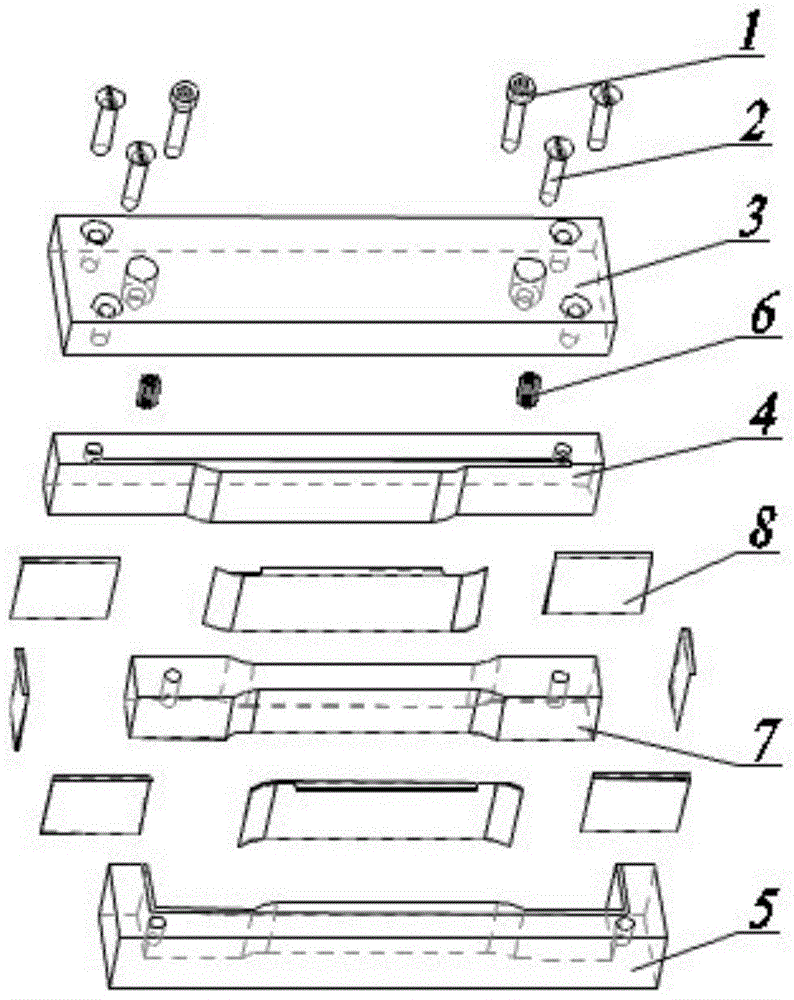

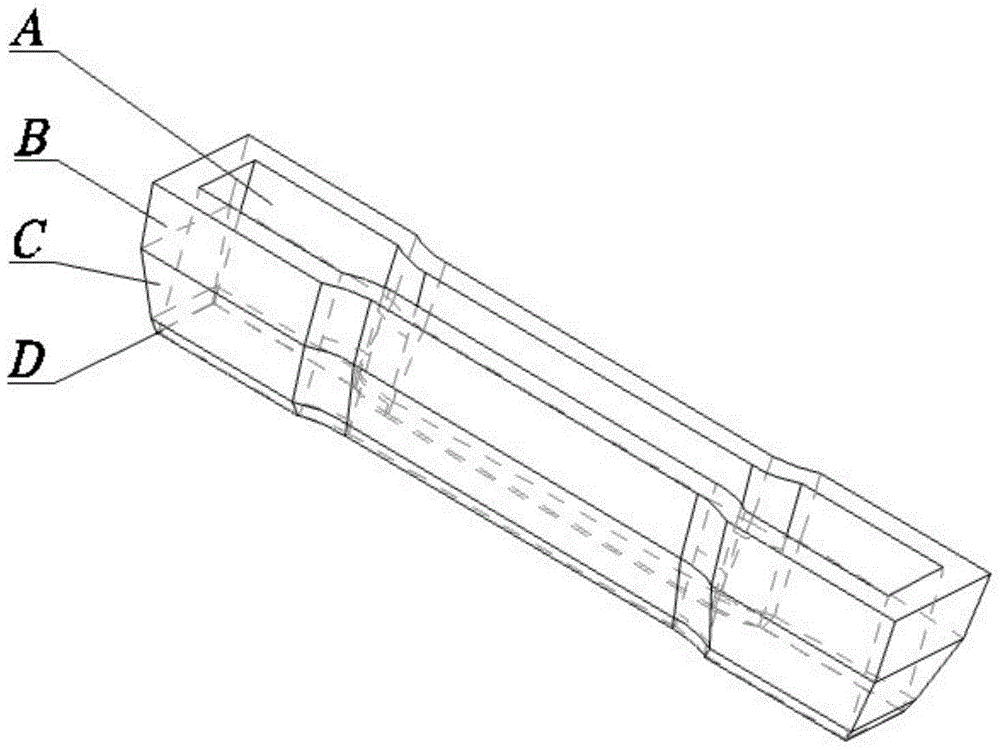

[0042] Such as Figure 1-2 As shown, this embodiment discloses a compound cutter device for sample preparation dumbbells, which mainly includes: a combined blade 8, a blade frame and a sample pushing mechanism. Above-mentioned combination blade 8 is dumbbell shape, and the frame interior shape of above-mentioned blade frame is the dumbbell shape that matches with above-mentioned combination blade, and promptly the profile of above-mentioned blade frame and combination blade fits, and blade frame is used for fixing combination blade 8.

[0043] Specifically, such as figure 1 , 2 , 12 and 13, the above-mentioned sample pushing mechanism is used to push the above-mentioned combination blade 8 and the blade frame. The above-mentioned sample pushing mechanism includes a cover plate 3, a spring 6 and a sample pushing block 7, and the above-mentioned cover plate 3 is sequentially pushed through the connector 2 1. The spring 6 is connected in series with the sample pushing block 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com