Wood door processing device

A processing device and wooden door technology, applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve problems such as low efficiency and low flatness of the plane, and achieve the effect of avoiding unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

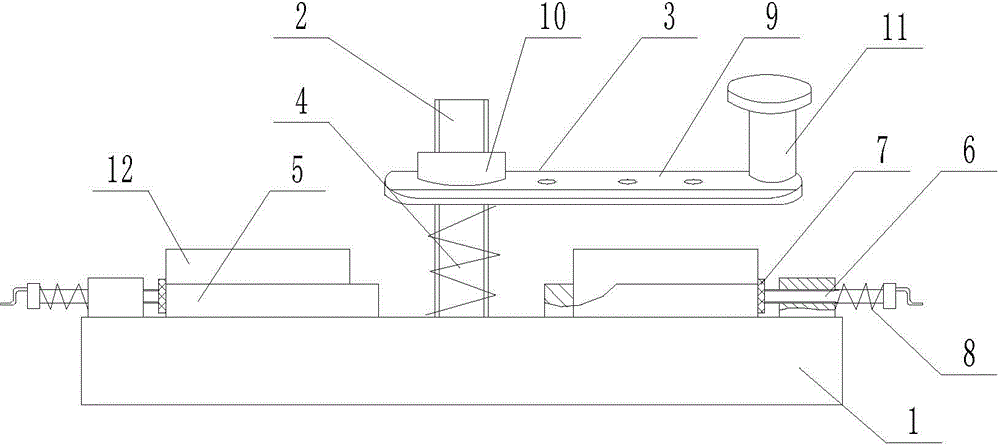

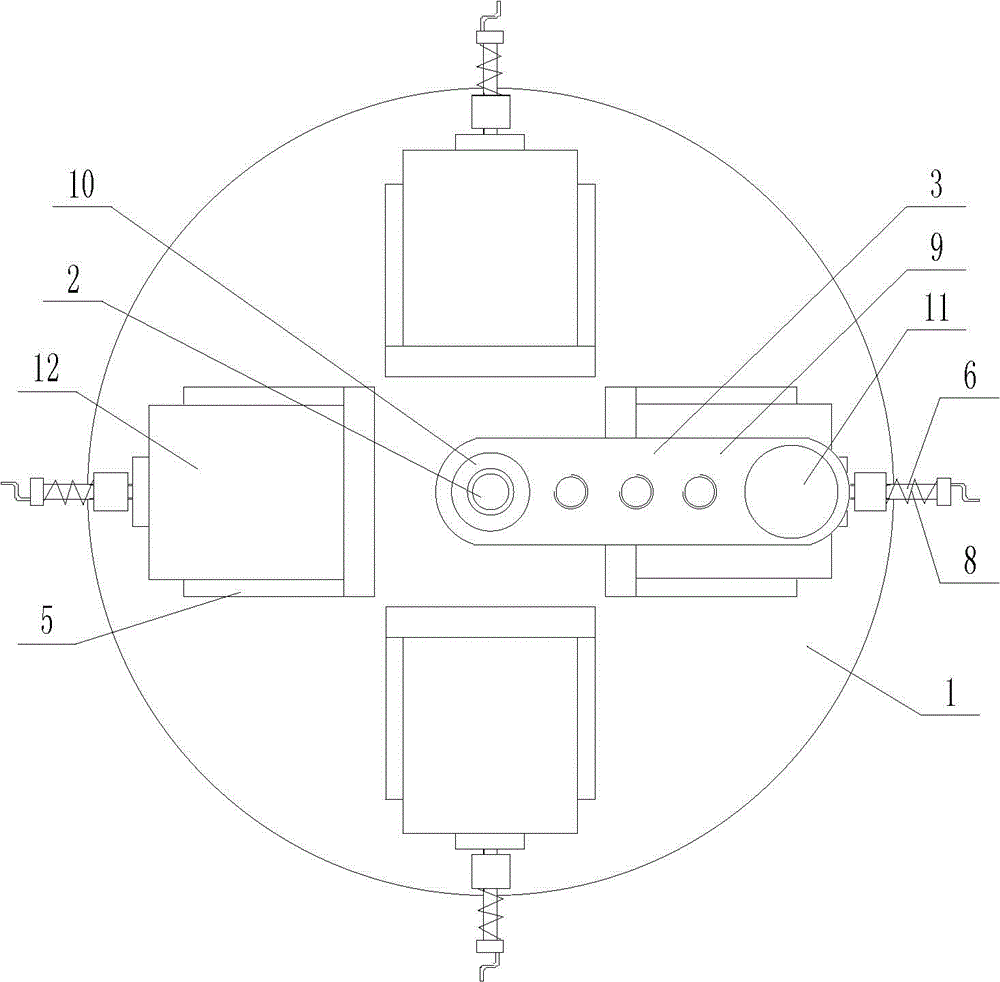

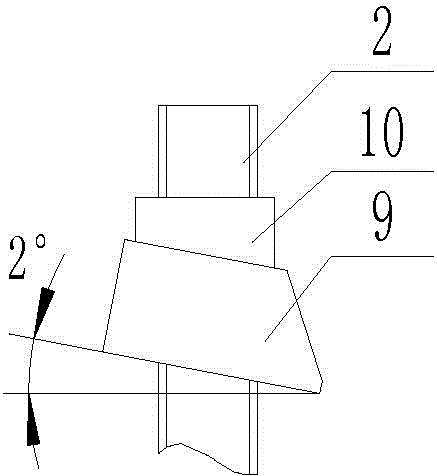

[0016] The reference signs in the accompanying drawings include: base 1, stud 2, cutter 3, first spring 4, deck 5, threaded rod 6, elastic block 7, second spring 8, blade 9, nut 10, knife Handle 11, wooden door 12.

[0017] The embodiment is basically as attached figure 1 , figure 2 , image 3 Shown: a wooden door 12 processing device, including a base 1, a stud 2 and a cutter 3; the cutter 3 and the stud 2 are threaded. The base 1 is disc-shaped, the stud 2 is located at the center of the base 1 , and the stud 2 is welded to the base 1 . A first spring 4 is provided between the cutter 3 and the base 1 , and the stud 2 is located inside the first spring 4 . The thread on the stud 2 is a double thread. Four decks 5 are evenly distributed on the base 1 . Card holder 5 is made up of a baffle plate and two side plates, and the thickness of baffle plate is 10 millimete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com