Buckle connecting quick-blocking plate

A fast blocking and looping technology, applied in the directions of ships, ship safety, transportation and packaging, etc., can solve the problems of insufficient freedom of adjacent thin plates, inability to flexibly change directions, etc., and achieve fast splicing, large degrees of freedom, and flexible deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention mainly aims at making further improvements on the Chinese patent "ship ring buckle connection speed blocking plate" (CN2011101757763). Therefore, in addition to the improved technical features, all other possible The technical characteristics used.

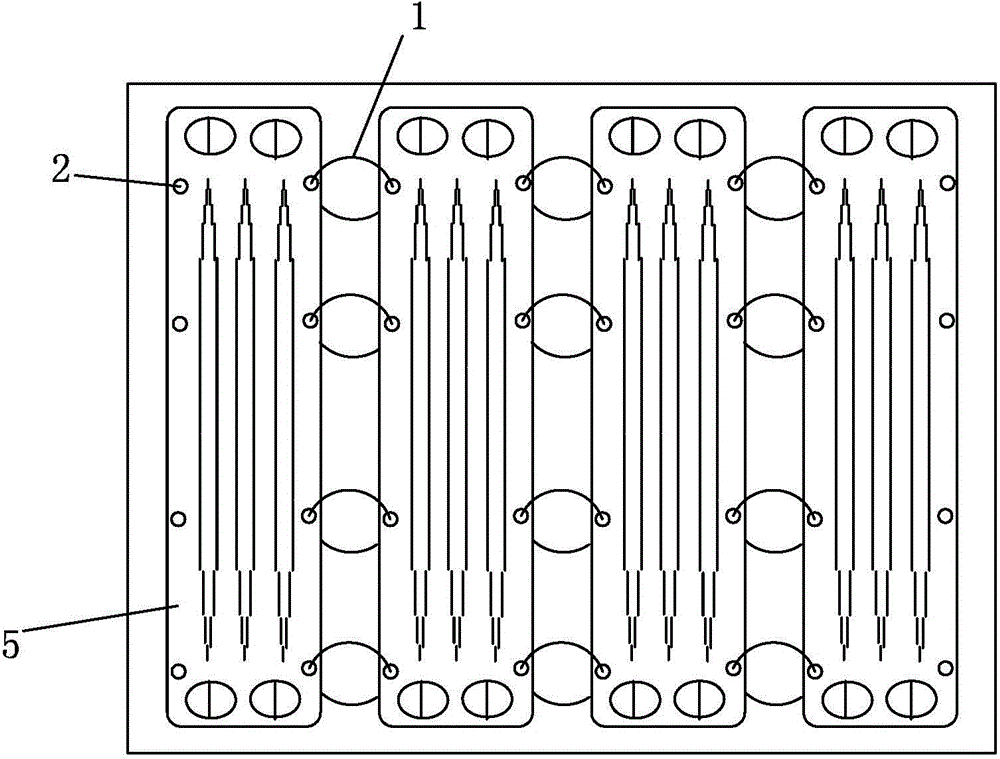

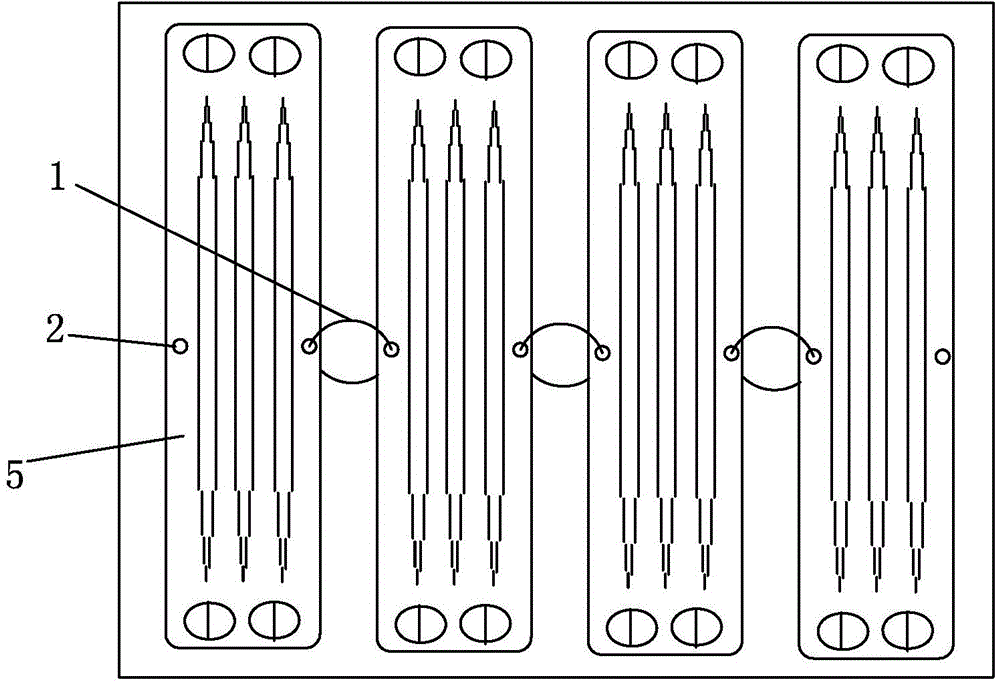

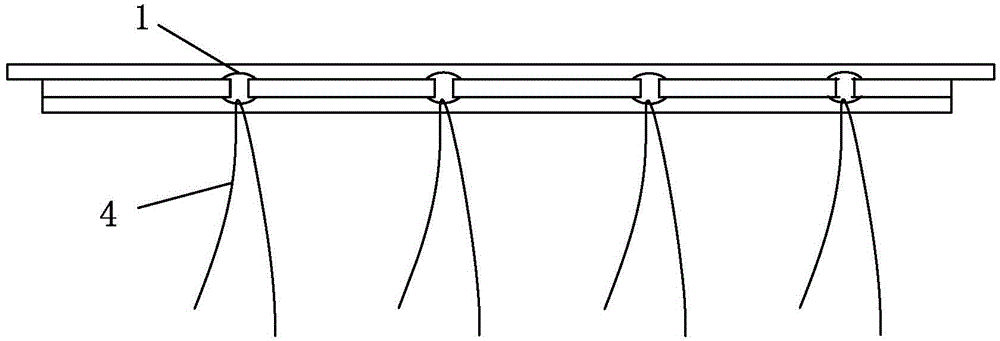

[0040] Specifically, the structure of the ring buckle connection quick blocking plate of the present invention, as Figure 1~3 As shown, it includes thin plates 5 connected in a straight line; two adjacent thin plates 5 are hinged to form a track form as a whole. Wherein, adjacent thin plates 5 are connected through openings through collars.

[0041] figure 1 In the illustrated embodiment, the adjacent thin plates 5 are correspondingly opened at intervals, and the corresponding holes are connected through collars. figure 2 In the shown embodiment, the adjacent thin plates 5 are connected through loops after opening corresponding holes in the middle, and this way has the greatest degree of freedom. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com