Elevator system for variably buffering damping force

An elevator system, cushioning and damping technology, which is applied in the field of safety systems for van elevators bottoming out, can solve problems such as complex structure, danger to passengers, and inability to use springs with elastic coefficients, so as to improve safety performance, comfort and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

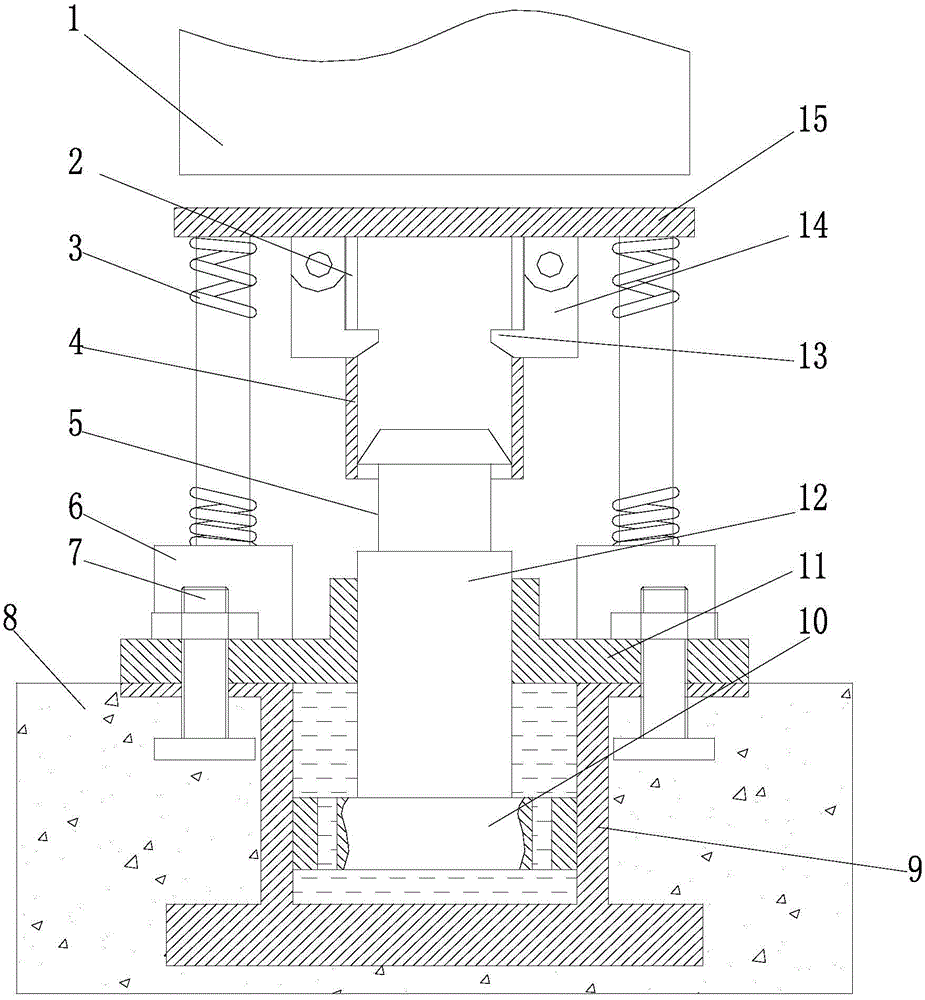

[0020] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the elevator system with variable buffer damping force in this embodiment includes an elevator car body 1 and a buffer assembly, and the buffer assembly includes a fixed arrangement at the bottom of the elevator shaft to prevent elevator Car body rigid bottoming buffer assembly; the buffer assembly includes a buffer spring 3 arranged on the foundation 8 and a buffer plate 15 supported on the top of the buffer spring 3, the buffer plate 15 faces the bottom of the elevator car body 1, and the buffer The spring 3 is a variable pitch spring; the foundation 8 refers to the foundation for the installation and construction of the buffer assembly; as shown in the figure, there is also a spring seat 6 for installing the buffer spring 3 on the foundation, which can be used to adjust the maximum compression of the spring 3 Stroke and limit compression position; the number of buffer spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com