Rack rail bullet train floor lightweight design method on basis of bionic design

A lightweight design and flooring technology, applied in the field of rail transit, can solve problems such as the inability to provide a variety of optimized structural options, and achieve high vibration resistance, reduce time-consuming, and optimize size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

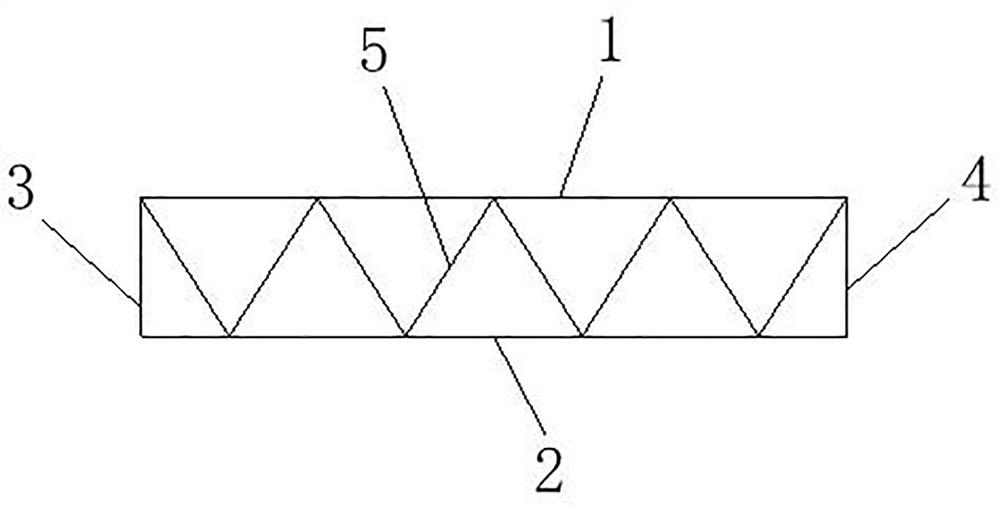

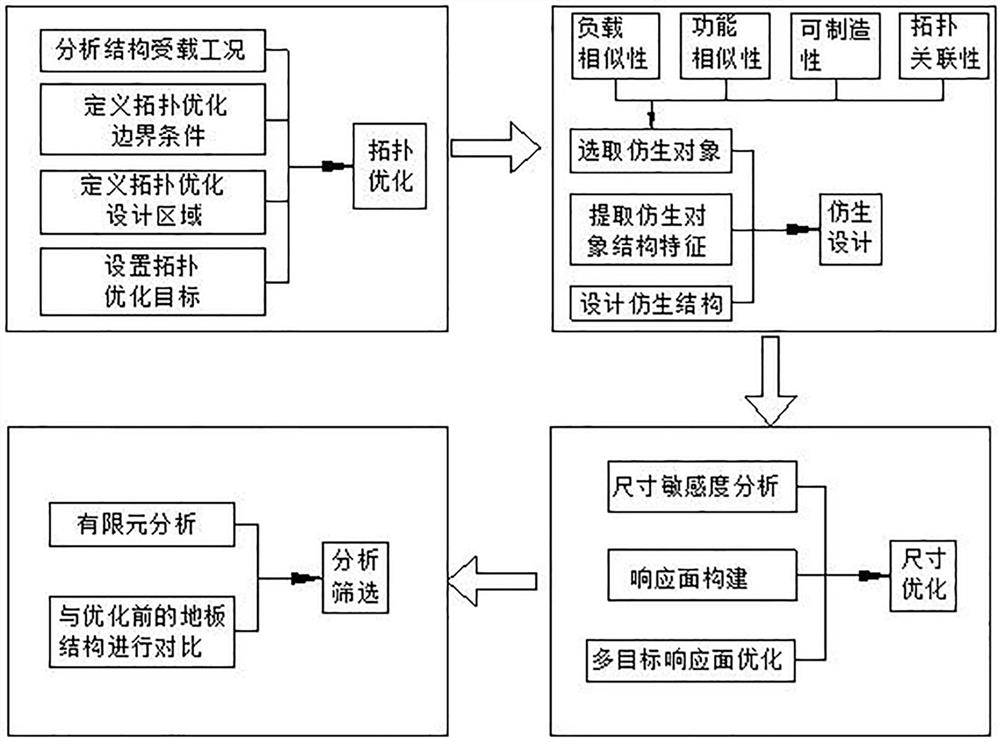

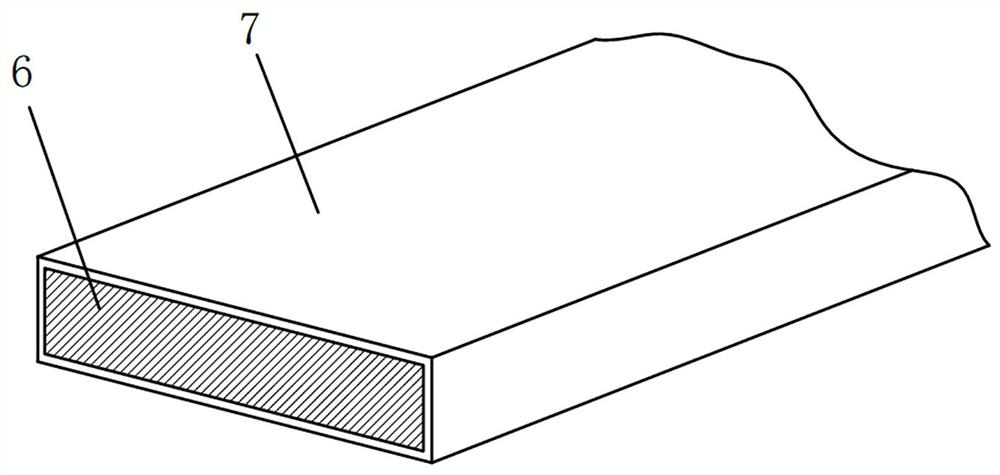

[0038] A lightweight design method for the floor of rack trains combined with bionic design, such as figure 2As shown, it includes the following steps: analyze the loading condition of the floor, and select the extreme condition as the boundary condition for topology optimization. Define the design area and non-design area for floor topology optimization. The goal of the topology optimization is set to be the minimum strain energy and the maximum natural frequency of the first-order sagging, and the extrusion manufacturing constraint along the longitudinal direction is added to constrain the mass fraction of the design area. After the parameter setting is completed, the topology optimization calculation is carried out to obtain the topology configuration. Several bionic floor structures are obtained by performing bionic design according to the topological configuration. Parameterize the size of each bionic floor structure, analyze the sensitivity of each size to the floor q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com