Blended yarn

A technology of blended yarn and yarn, which is applied in the direction of yarn, textile, papermaking, dyeing, etc., can solve the problems of insufficient crispness and easy deformation of fabrics, and achieve the effect of not being easy to scatter, not easy to pilling, and improving layers and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

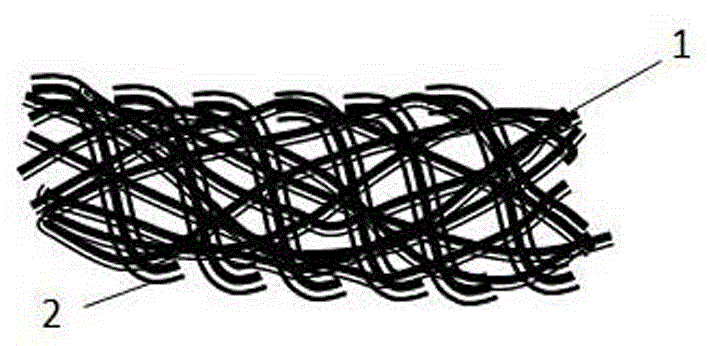

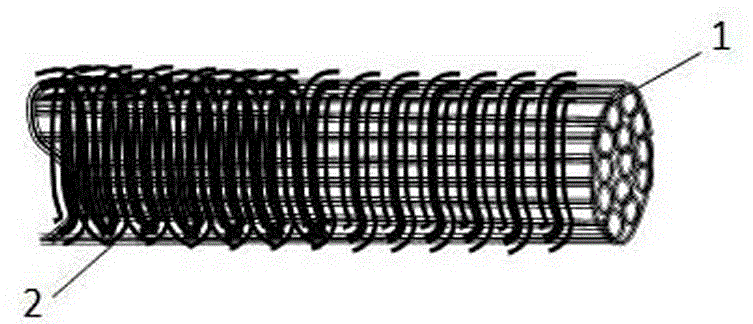

[0035] Embodiment 1: a kind of blended yarn, including resilient fiber 1 and support fiber 2 partially wound on said resilient fiber 1, said resilient fiber is a plurality of cashmere fibers with a fineness of 1tex twisted and twisted The supporting fiber is a long-staple cotton fiber with a fineness of 10tex, which is reversely twisted on the cashmere fiber, and the winding angle is 35°. There is an outer leakage part of the cashmere fiber 1 between the long-staple cotton fibers 2, and the outer The leakage area accounts for 10% of the surface area of the yarn, and natural dyes are used to dye the long-staple cotton fibers.

Embodiment 2

[0036] Embodiment 2: a kind of blended yarn, comprises resilience fiber 1 and the support fiber 2 that part is wound on described resilience fiber 1, and described resilience fiber is fineness: the cashmere fiber of 80tex and cotton fiber are twisted through twisting The supporting fiber is a long-staple cotton fiber with a fineness of 50tex, which is reversely twisted on the cashmere / cotton mixed fiber with a winding angle of 55°, and there is an outer layer of the cashmere / cotton fiber between the long-staple cotton fibers 2. The leakage part, the area of the leakage part accounts for 30% of the surface area of the yarn, and the long-staple cotton fibers are dyed with natural dyes.

Embodiment 3

[0037] Embodiment 3: a kind of blended yarn, comprising resilient fiber 1 and supporting fiber 2 partially wound on said resilient fiber 1, said resilient fiber is a parallel fiber bundle of a plurality of cashmere fibers with a fineness of 130tex, The supporting fiber is a long-staple cotton fiber with a fineness of 145tex, which is divided into two layers and wound on the cashmere fiber with the opposite twist direction, the winding angle is 85°, and there is an outer leakage part of the cashmere fiber 1 between the long-staple cotton fibers 2 , the area of the leaking part accounts for 50% of the surface area of the yarn, the long-staple cotton fibers are dyed with natural dyes, and the polysiloxane-modified polyurethane and polymer epoxy polyether amino-modified polysiloxane Soak in the finishing agent compounded with alkanes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com