Polyethylene film with resealing function and preparation method thereof

A technology of polyethylene film and sealing function, which is applied in the field of polyethylene film with resealable function and its preparation, which can solve the problems of easy loss of odor of items, increase of packaging bag process, and easy dampness of items, so as to achieve no sense of frustration in hand feeling , smooth hand feeling, good anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

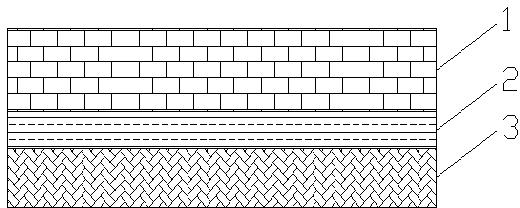

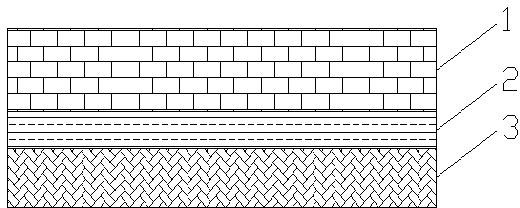

[0034] A polyethylene film with a resealable function such as figure 1 As shown, the heat-sealing layer, middle layer and corona layer are produced by co-extrusion blown film, 1 is the corona layer, 2 is the middle layer, 3 is the heat-sealing layer, the corona layer, middle layer, heat-sealing layer The interlayer thickness ratio of the layers is 5:2:4, and the total thickness is 44 μm.

[0035] The heat-sealing layer is composed of 33% low-density polyethylene (LDPE), 66% linear low-density polyethylene (LLDPE), 0.7% slip agent oleic acid amide, and 0.3% polyurethane defoamer;

[0036] The middle layer is a modified ethylene-vinyl acetate copolymer hot melt adhesive, which consists of 70% ethylene-vinyl acetate copolymer (EVA), 25% tackifier petroleum resin, and 2% leveling agent modified polysiloxane Alkanes copolymer, 2% 2,6-di-tert-butylphenol antioxidant and 1% polyurethane defoamer.

[0037] The corona layer is low density polyethylene (LDPE).

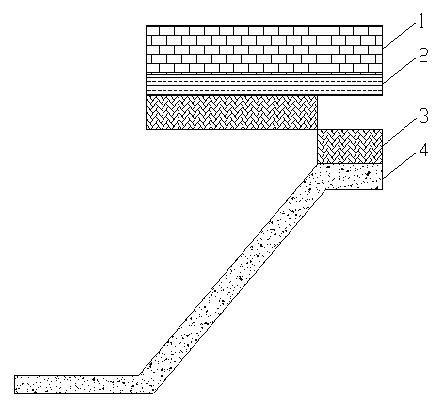

[0038] Such as figu...

Embodiment 2

[0048] A polyethylene film with a resealable function is a three-layer co-extruded polyethylene film (PE), which is a corona layer, an intermediate layer, and a heat-sealing layer from the outside to the inside, and the thickness ratio between layers is 5.5: 2.5:4, the total thickness is 48μm.

[0049] The heat-sealing layer is composed of 33% low-density polyethylene (LDPE), 66% linear low-density polyethylene (LLDPE), 0.6% slip agent erucamide, and 0.4% polyurethane defoamer.

[0050] The middle layer is a modified ethylene-vinyl acetate copolymer hot melt adhesive, which consists of 45% ethylene-vinyl acetate copolymer (EVA), 50% tackifier rosin, and 3% leveling agent modified polysiloxane Copolymer, 1% 2,6-di-tert-butylphenol antioxidant and 1% polyurethane defoamer.

[0051] The corona layer is low density polyethylene (LDPE).

[0052] The peeling mode and resealing mode of the polyethylene film with resealable function in the embodiment of the present invention are the...

Embodiment 3

[0058] A polyethylene film with a resealable function is a three-layer co-extruded polyethylene film (PE), which is a corona layer, an intermediate layer, and a heat-sealing layer from the outside to the inside, and the thickness ratio between layers is 4.5: 1.5:3.5, the total thickness is 50μm.

[0059] The heat-sealing layer is composed of 49% low-density polyethylene (LDPE), 50% linear low-density polyethylene (LLDPE), 0.5% slip agent oleic acid amide and 0.3% slip agent erucamide, 0.2% slip agent Composition of polyurethane defoamer.

[0060] The middle layer is a modified ethylene-vinyl acetate copolymer hot melt adhesive, which consists of 56% ethylene-vinyl acetate copolymer (EVA), 40% tackifier petroleum resin, and 2% leveling agent modified polysiloxane Alkanes copolymer, 1.5% 2,6-di-tert-butylphenol antioxidant and 0.5% polyurethane defoamer.

[0061] The corona layer is low density polyethylene (LDPE).

[0062] The peeling mode and resealing mode of the polyethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com