High-count high-density pure-cotton twilled satin shell fabric and processing process thereof

A high-count, high-density, processing technology, applied in the direction of textile, biochemical fiber treatment, fabric, etc., to achieve the effect of ensuring product quality, good moisture absorption and air permeability, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with embodiment.

[0043] 1. Product Design

[0044] 1. Yarn design

[0045] In order to achieve the light, smooth and delicate design effect of imitation silk, the warp and weft yarns are all made of combed 5.8tex pure cotton yarn, so as to ensure the ideal style effect and the physical indicators of the fabric meet the requirements of imitation silk fabric.

[0046] 2. Fabric design

[0047] In terms of fabric design, in order for the pure cotton fabric to achieve the luster of silk, soft, smooth, smooth feel, and comfortable to wear, the fabric needs to be relatively thin, so five three-flying Zhigong weaves were chosen. The specifications of the finished product are designed as follows: the warp and weft yarns are all combed 5.8tex pure cotton yarns, the warp density of the fabric is 905.5 threads / 10cm, the weft density is 866 threads / 10cm, and the width is 143cm.

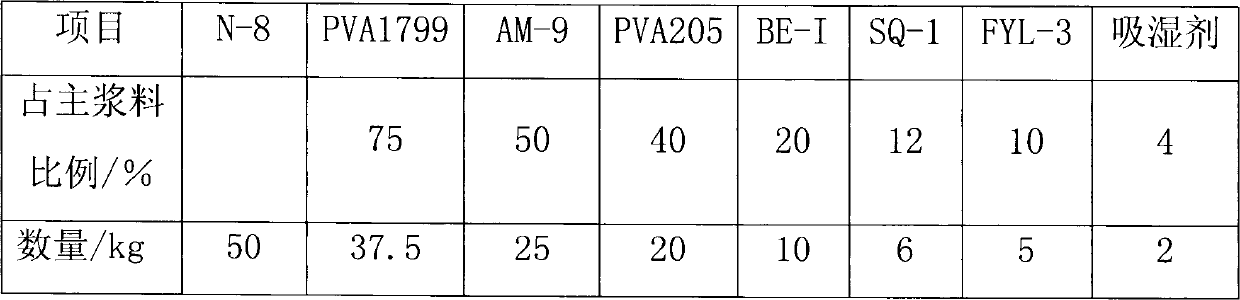

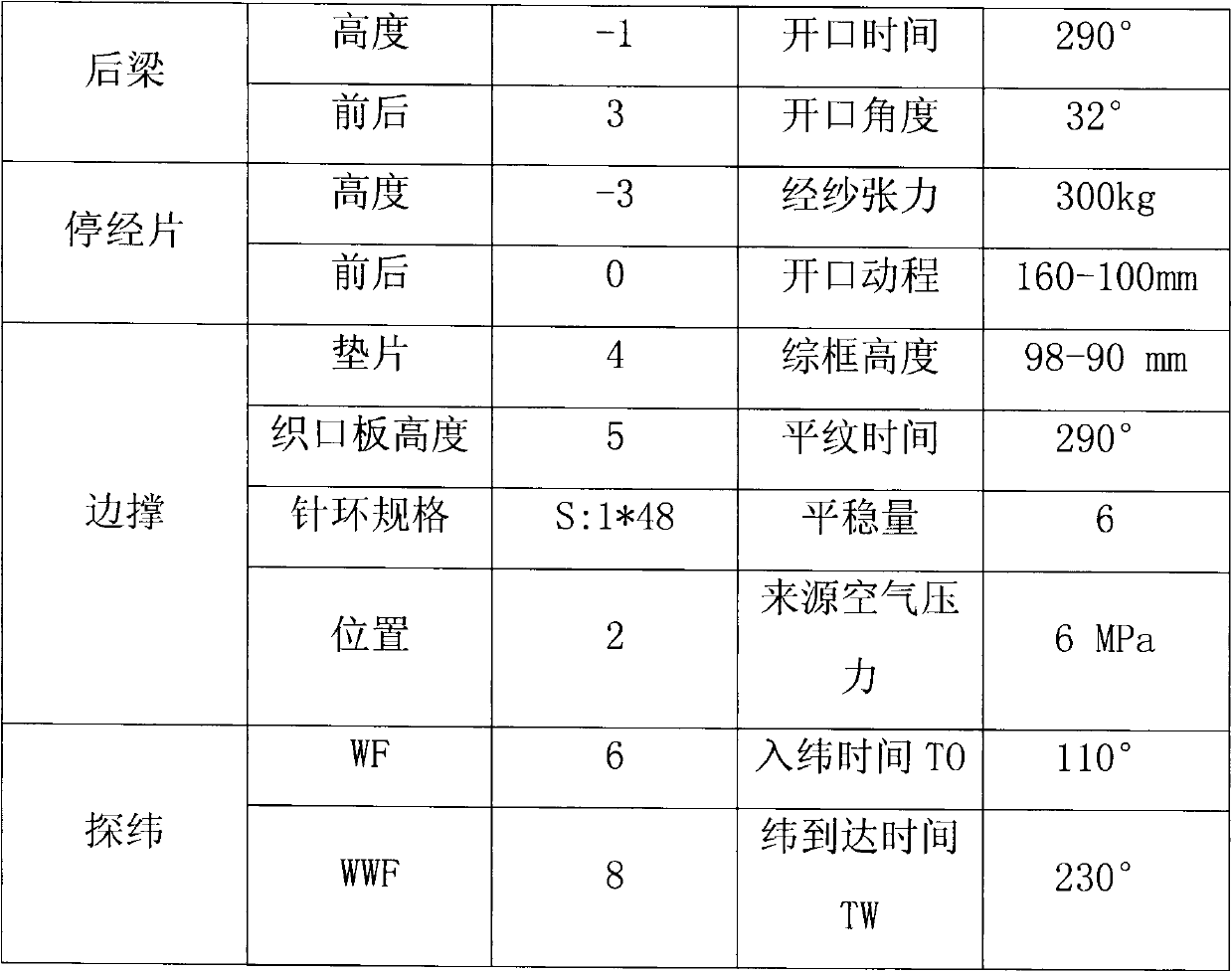

[0048] 2. Key points of proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com