Smooth polishing treating agent and preparation technology thereof

A preparation process and treatment agent technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of poor oil permeability and hand feeling on leather surface, poor temperature resistance effect, etc., achieve good black haze and improve temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

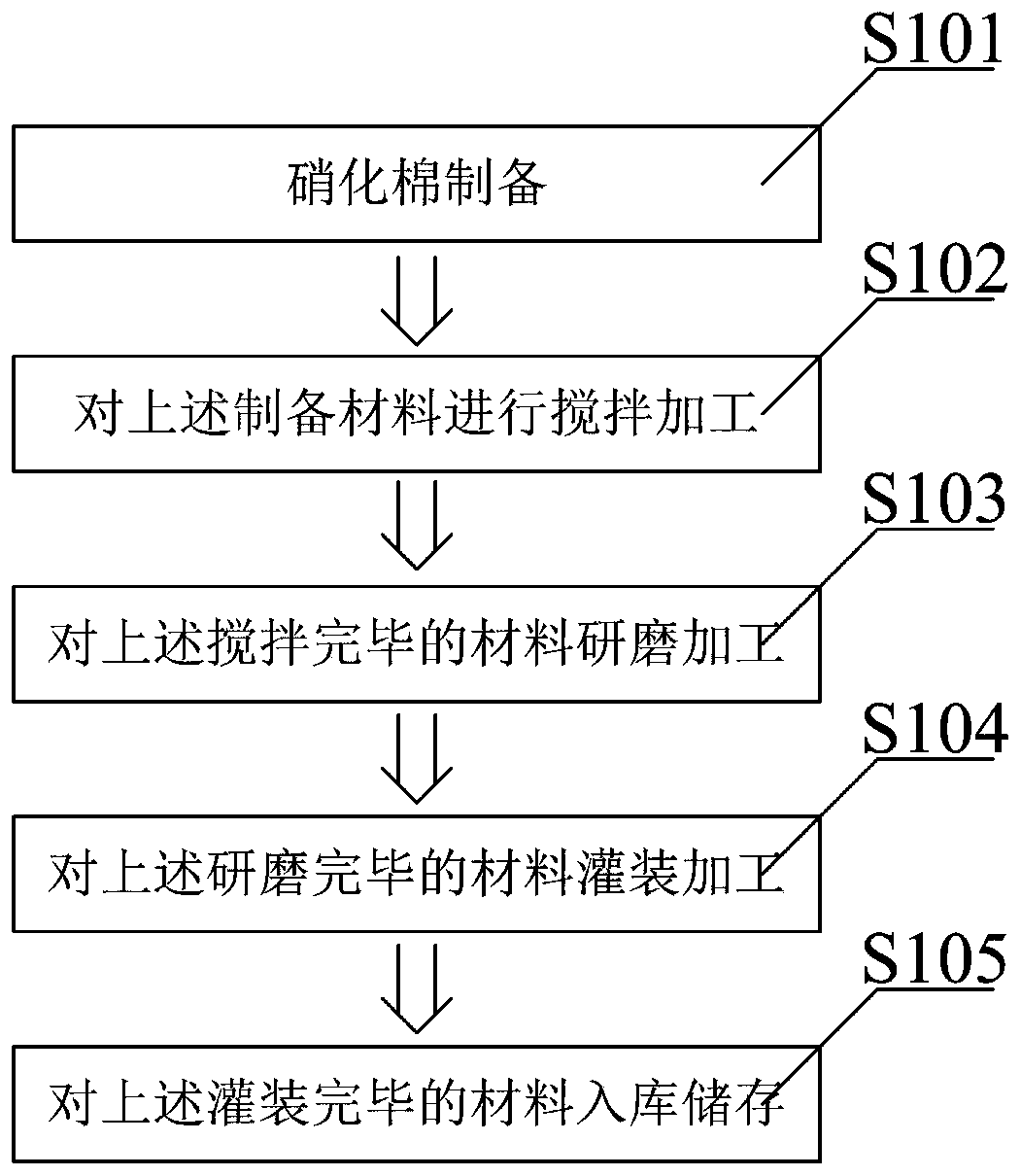

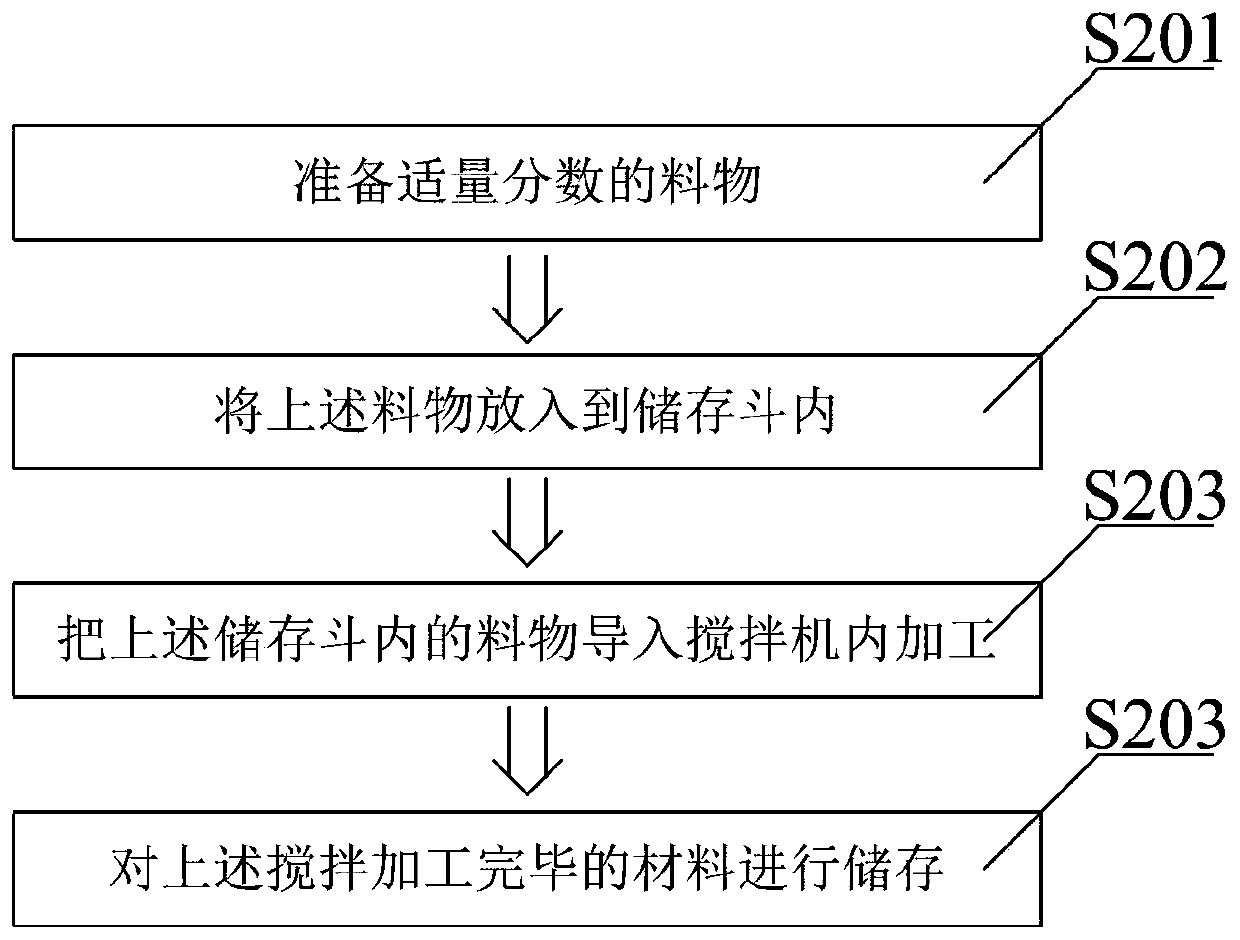

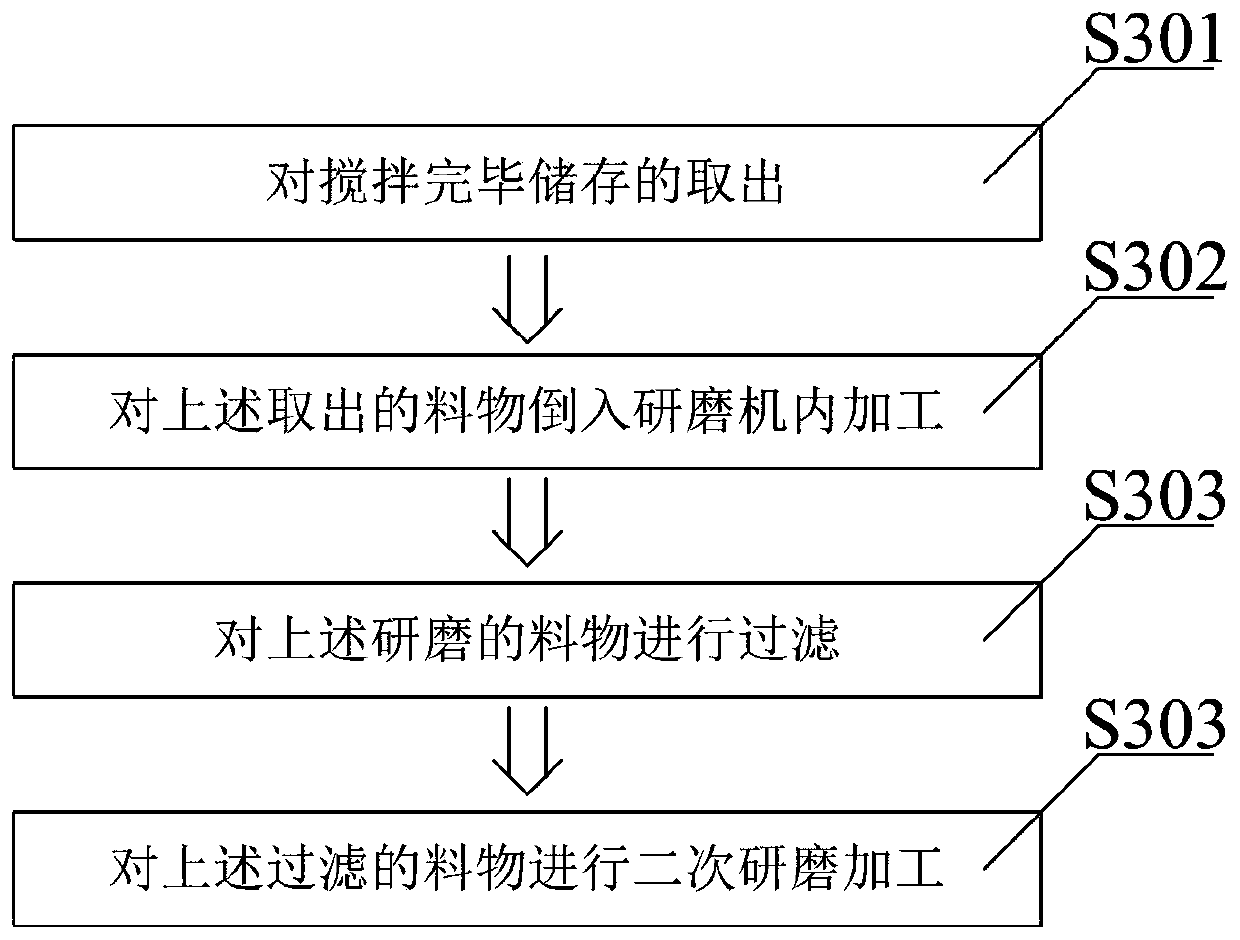

[0071] Example 1: First, use 3:1 nitrocellulose powder and butyl acetate as raw materials for nitrocellulose pulp, and put them in a storage hopper for precipitation for a certain period of time, then pour the material into a mixer for stirring and processing, and stir for a certain period of time. , take out the mixed material from the mixer, and put it into the storage box for storage for a certain period of time, take out the material in the storage box, and add it to the grinder for a certain period of time, after grinding, use the filter bucket to grind The above-mentioned ground materials are filtered, then the above-mentioned filtered materials are poured into the grinder for secondary grinding for a certain period of time, and then the ground qualified materials are poured into the finished product tank for filling, and finally the above-mentioned finished product tank is packaged, and Store in warehouse.

Embodiment 2

[0072] Example 2: First, use 2.5 to 1 nitrocellulose powder and butyl acetate as the raw material of nitrocellulose pulp, and put it into a storage bucket for precipitation for ten to twenty minutes, then pour the material into a mixer and stir for processing , Stir for 20 to 30 minutes, take out the stirred materials from the mixer, and put them in the storage box for storage for 15 to 20 minutes, take out the materials in the storage box, and add them to the Grind in the grinder for 15 to 20 minutes. After grinding, use the filter bucket to filter the above-mentioned ground materials, and then pour the above-mentioned filtered materials into the grinder for secondary grinding for 10 to 15 minutes, and then Pour the ground qualified material into the finished product tank for filling, and finally the above-mentioned finished product tank is packaged and stored in the warehouse for storage.

Embodiment 3

[0073] Embodiment 3: First, use 2:1 nitrocellulose powder and butyl acetate as the raw material of nitrocellulose pulp, and put it into a storage bucket for precipitation for 15 to 20 minutes, then pour the material into the mixer and stir for processing. Stir for 25 minutes to 30 minutes. Take out the mixed materials from the mixer and put them in the storage box for storage for 15 to 20 minutes. Take out the materials in the storage box and add them to the Grind in the grinder for 18 to 20 minutes. After grinding, filter the above-mentioned ground materials with a filter bucket, and then pour the above-mentioned filtered materials into the grinder for secondary grinding for 10 to 13 minutes. , Then pour the ground qualified material into the finished product tank for filling, and finally the above-mentioned finished product tank is packaged and stored in the warehouse for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com