Gasoline filter element

A technology of filter element and gasoline, which is applied in fixed filter element filter, filter separation, liquid fuel feeder, etc. It can solve problems such as difficulty in reaching all qualifications, pollution, and reduced filter element life, and achieve reliability problems and high filtration efficiency. The effect of precision and good oil permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

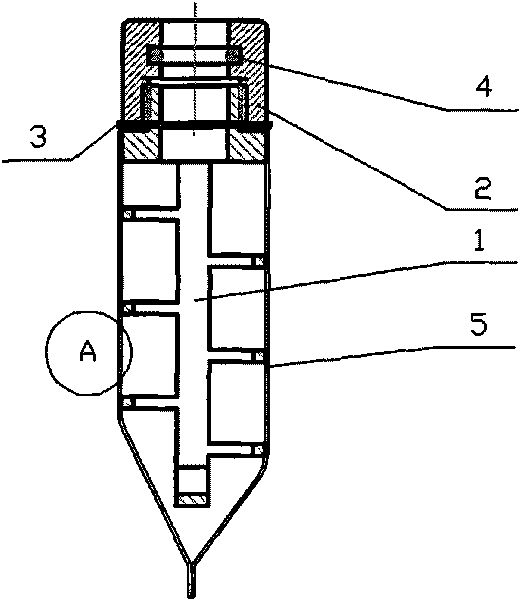

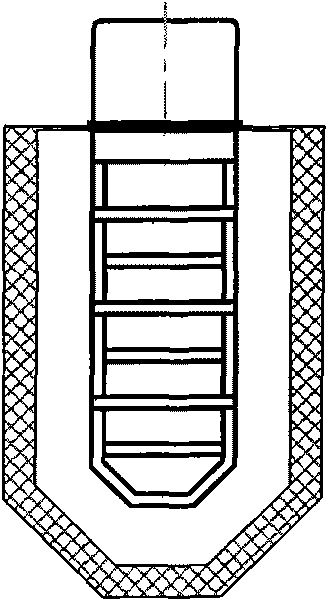

[0020] Embodiment: as shown in Figure 1 (a), the gasoline filter element of the present invention comprises skeleton (1), lock nut (2), flat gasket (3), seal ring (4), multi-layer filter cloth (5) .

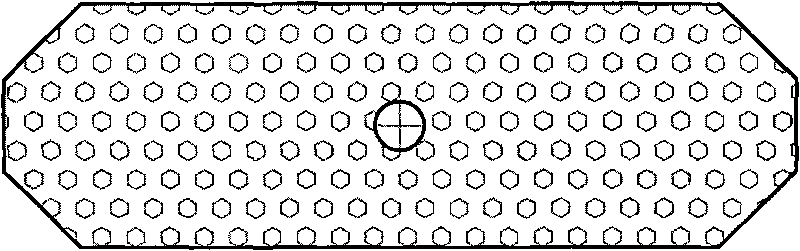

[0021] As shown in Fig. 1(c), before the multi-layer filter cloth (5) is made, ultrasonic spot welding is used to separate the mesh cloth into evenly distributed oil passage blocks through the spot welding points. Spot welds are round. If the spot welding array is too dense, the circulation area of gasoline will be greatly reduced; if the spot welding array is too sparse, the area of the oil passage block will be large, and the meshes between the multi-layer filter cloths will be loose. , It is not conducive to the circulation of gasoline, causing the oil permeability or lipophilicity of the gasoline filter element to be greatly reduced.

[0022] The open end of the multi-layer filter cloth (5) passes through the frame (1), the lock nut (2) presses the multi-layer filter cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com