Cast-in-place concrete pile air bubble elimination casting device

A technology of air bubble elimination and cast-in-place pile, which is applied in construction and foundation structure engineering, etc., and can solve problems such as difficulty in vibrating, concrete pouring pile vibrating, mixing difficulty, and inability to reach the vibrator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

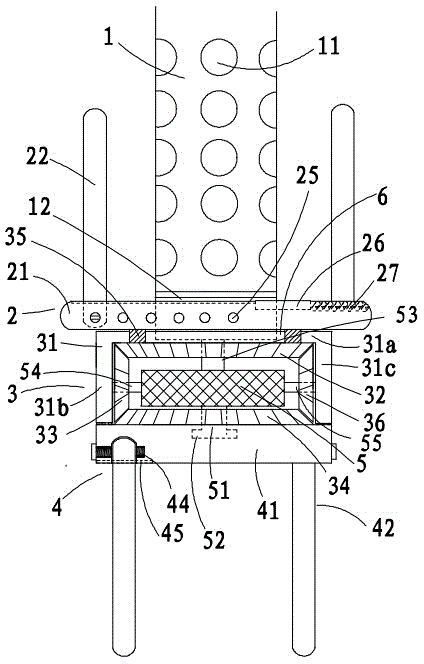

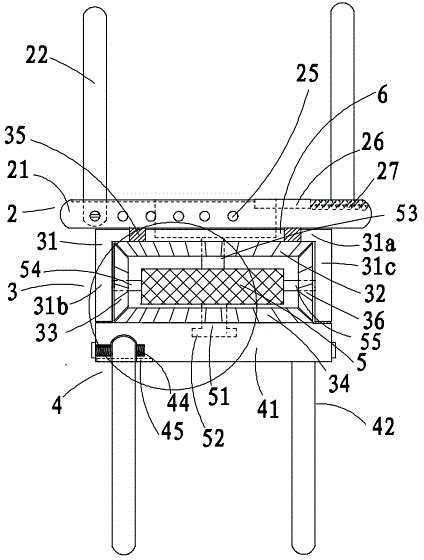

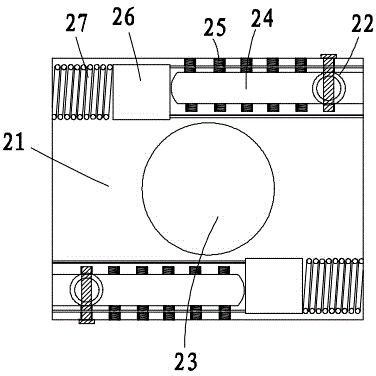

[0028] Figure 1 to Figure 14 Shown is the structural representation of the present invention.

[0029] The reference signs are: pouring pipe 1, discharge hole 11, fixed port 12, upper stirring device 2, upper rotating plate 21, upper stirring column 22, upper plate center hole 23, upper adjusting groove 24, upper adjusting fixing hole 25. Push-up plate 26, push-up spring 27, middle transmission structure 3, transmission support 31, top support plate 31a, left support plate 31b, right support plate 31c, top helical gear 32, left helical gear 33, bottom Helical gear 34, connecting column 35, right side helical gear 36, bottom stirring device 4, lower rotating plate 41, lower stirring column 42, lower adjustment groove 43, lower adjustment fixing hole 44, lower push plate 45, lower push spring 46, Motor 5, power transmission shaft 51, shaft hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com