A production process of fireproof and thermal insulation composite laminate

A technology of fire prevention and heat preservation and production technology, which is applied in the direction of heat preservation, fire protection, and layered products, etc. It can solve the problems of large amount of glue used, complex production process of fire insulation board, and complicated production process, so as to achieve small thermal conductivity and avoid a large amount of adhesive The use of the heat insulation performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

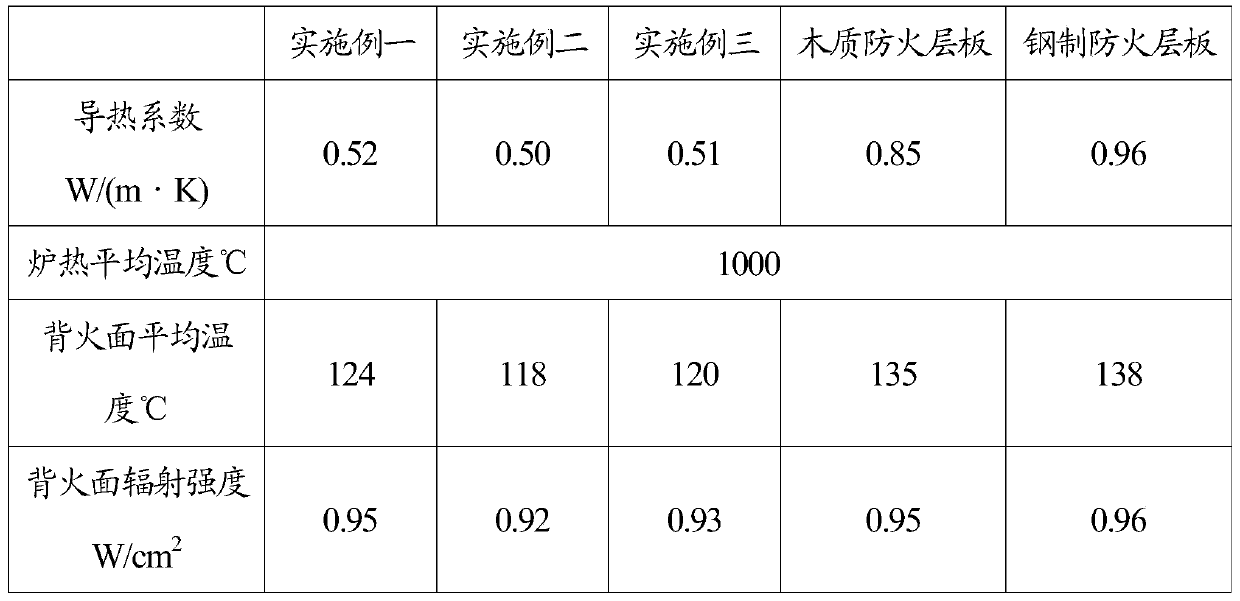

Embodiment 1

[0020] A production process of a fireproof and thermal insulation composite laminate, the production process comprises the following steps:

[0021] (1) Laminate preparation and molding: mix the fireproof and heat preservation components according to a certain ratio, and cast them to form a single-layer laminate;

[0022] (2) Laminate material processing: put each layer of the laminate into a controllable constant temperature device, raise the temperature of the laminate to 80°C and maintain it for 75min, and then cool down to 50°C at a constant cooling rate of 2°C / min;

[0023] (3) Pressure curing: place each layer of laminates in a certain order, and use a single-plate press to cure at 50°C for 15 minutes. The pressure in the press is 3-4kg / cm 2 .

[0024] A fireproof and thermal insulation composite laminate is produced according to the above production process.

Embodiment 2

[0026] A production process of a fireproof and thermal insulation composite laminate, the production process comprises the following steps:

[0027] (1) Laminate preparation and molding: mix the fireproof and heat preservation components according to a certain ratio, and cast them to form a single-layer laminate;

[0028] (2) Laminate material processing: Put each layer of laminates into a controllable constant temperature device, raise the temperature of the laminates to 100°C and maintain it for 95 minutes, and then cool down to 60°C at a constant cooling rate of 5°C / min;

[0029] (3) Pressure curing: place each layer of laminates in a certain order, and use a single-plate press to cure at 60°C for 20 minutes. The pressure in the press is 3-4kg / cm 2 .

[0030] A fireproof and thermal insulation composite laminate is produced according to the above production process.

Embodiment 3

[0032] A production process of a fireproof and thermal insulation composite laminate, the production process comprises the following steps:

[0033] (1) Laminate preparation and molding: mix the fireproof and heat preservation components according to a certain ratio, and cast them to form a single-layer laminate;

[0034] (2) Laminate material treatment: put each layer of laminate into a controllable constant temperature device, raise the temperature of the laminate to 90°C and maintain it for 80min, and then cool down to 55°C at a constant cooling rate of 4°C / min;

[0035] (3) Pressure curing: place each layer of laminates in a certain order, and use a single-plate press to cure at 55°C for 20 minutes. The pressure in the press is 3-4kg / cm 2 .

[0036] A fireproof and thermal insulation composite laminate is produced according to the above production process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com