Buckle plate and sound insulation and heat insulation structure utilizing same for building

A technology for construction and gusset, applied in building components, sound insulation, thermal insulation, etc., can solve the problems of structural nodes, immature installation process, narrow application range, weak bonding, etc., to eliminate potential safety hazards and overcome easy falling off. , Good sound insulation and shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

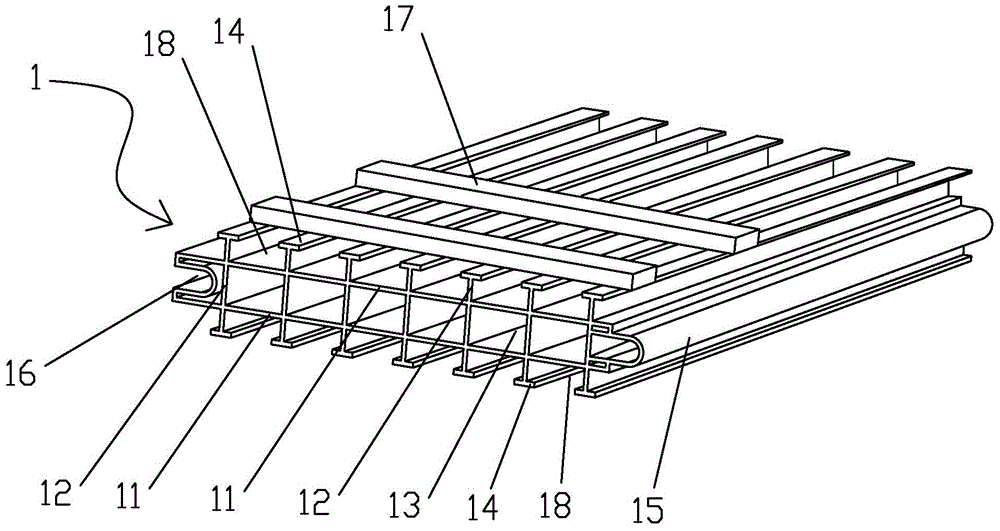

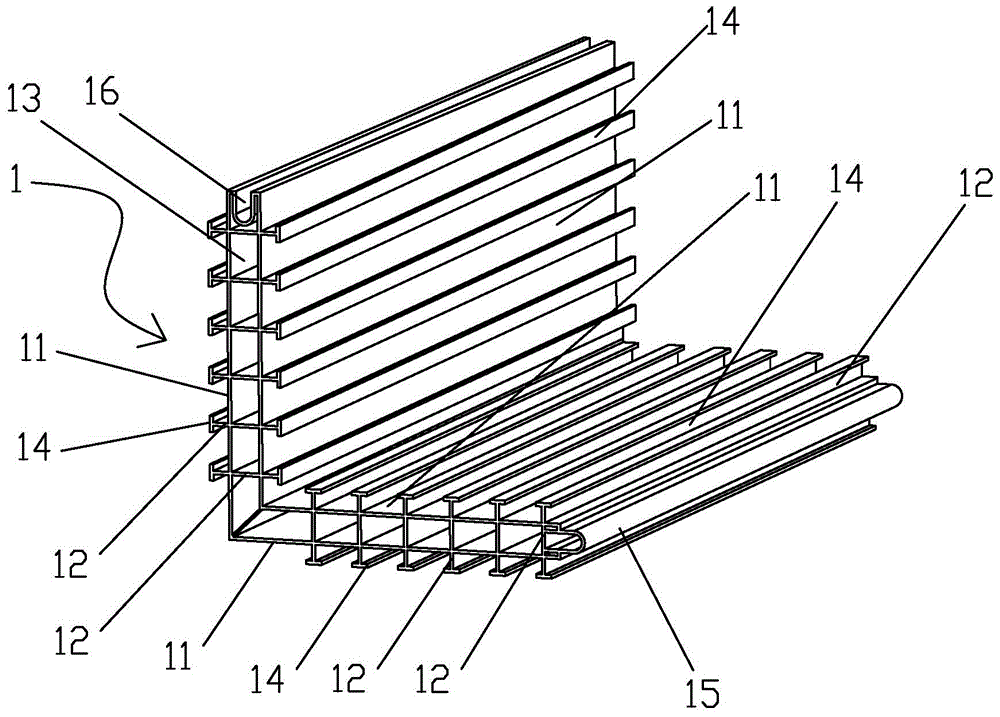

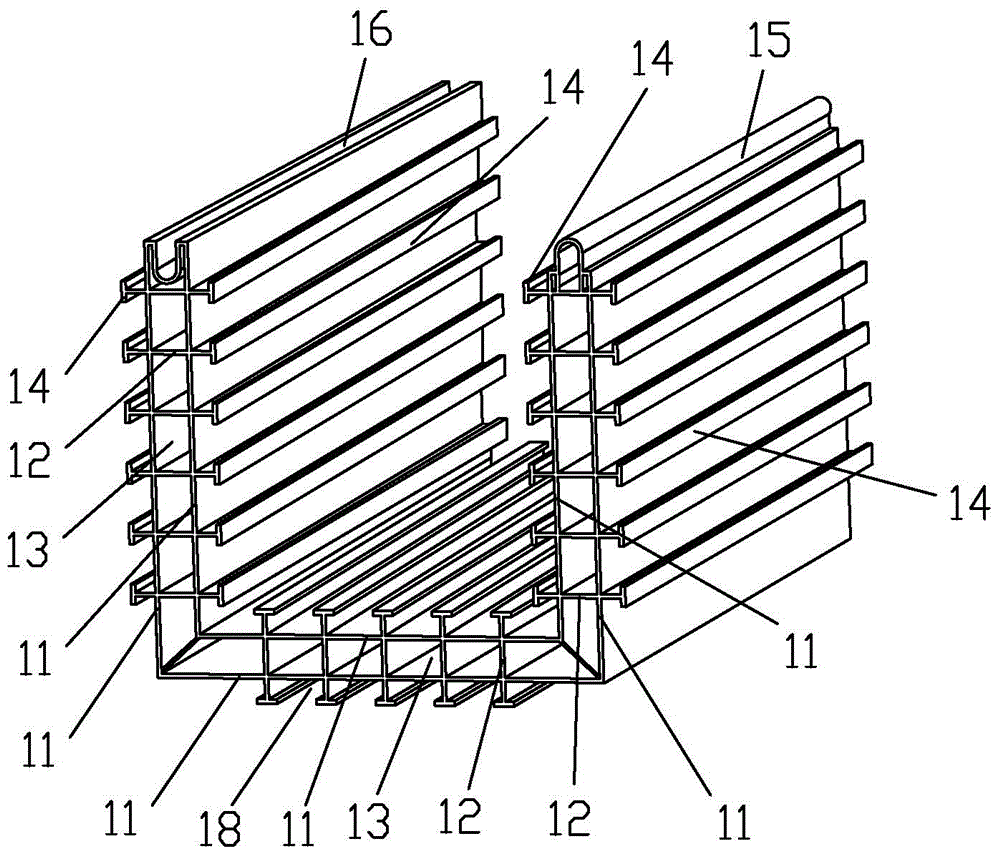

[0037] A buckle plate 1, comprising a base plate 11 arranged at intervals and a plurality of spacer plates 12 connected obliquely or vertically to the base plate 11 and protruding from the outside of the base plate 11, the spacer plates 12 and the base plate 11 are surrounded by a plurality of spaced The cavity 13 of the spacer plate 12 protrudes from the same side of the substrate 1 to form a spacer 18 between each other. The connecting tooth plates 14 on both sides. The buckle plate 1 is integrally injection molded. When the gusset 1 is horizontally arranged between the bottom of the floor and the plastering layer, the gusset 1 is set under the concrete ceiling, and the concrete material and the plastering material on the lower side of the gusset 1 are embedded in the compartment 18, and the gusset 1 and the concrete The floor slab and the plaster layer applied on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com