Sealing strip for passive gap adjusting friction starting steam turbine sealing

A technology for adjusting the gap and the steam seal, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc. It can solve the problems of excessive steam seal gap, rotor journal damage, large steam quality and flow loss, etc. Good quality, good adjustment effect, and the effect of reducing the steam seal gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

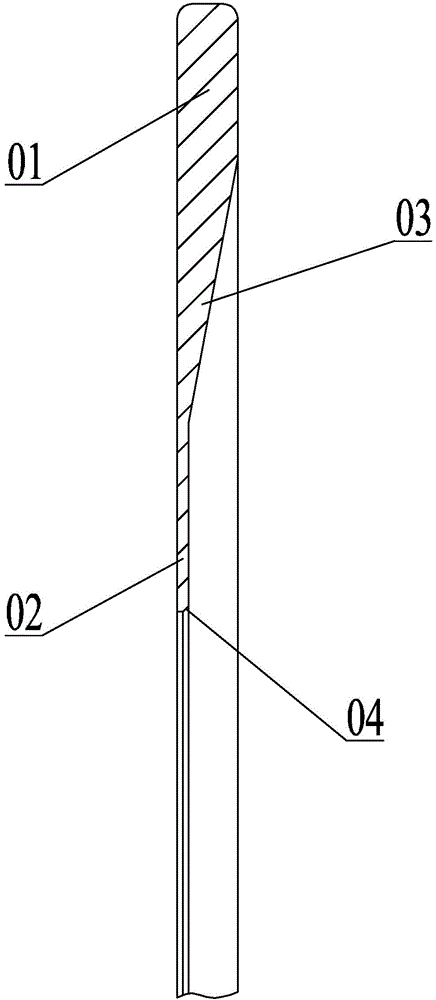

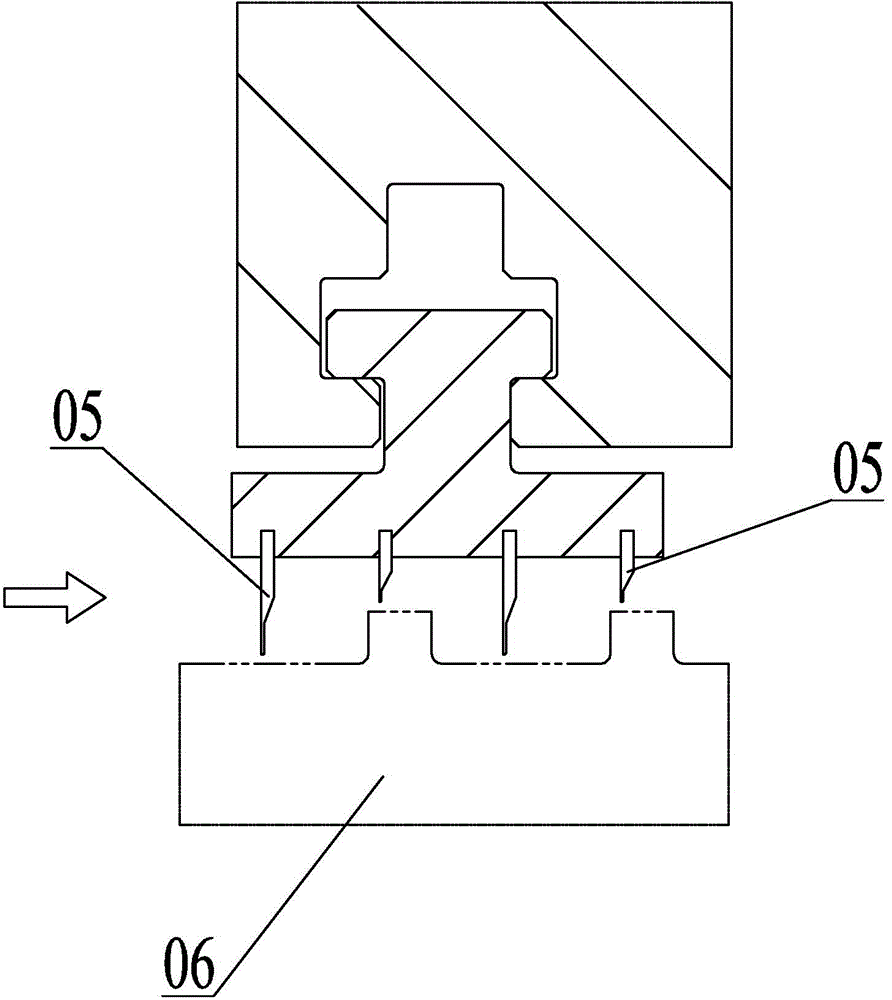

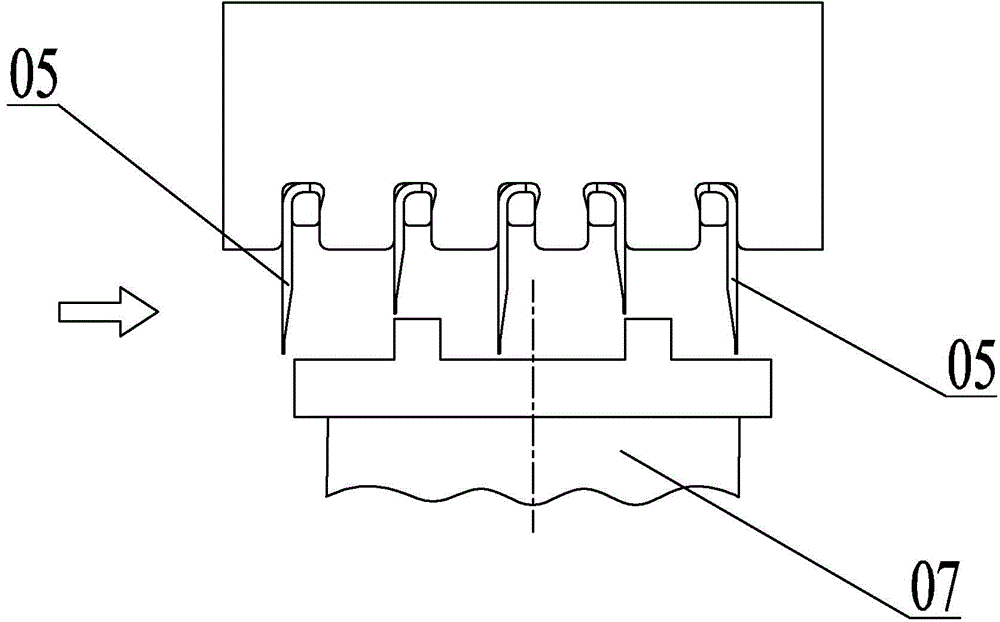

[0012] Specific implementation mode one: combine Figure 1 to Figure 3 Note that the steam sealing sheet in this embodiment is a ring sheet, and the steam sealing sheet is composed of a first ring sheet 01, a second ring sheet 02 and a transition ring sheet 03, and the diameter of the first ring sheet 01 is larger than that of the second ring sheet. The diameter of piece 02, the second ring piece 02, the transition ring piece 03 and the first ring piece 01 are connected vertically in sequence, the thickness of the first ring piece 01 is greater than the thickness of the second ring piece 02, and the thickness of the inner ring of the transition ring piece 03 is the same as The thickness of the second ring piece 02 is consistent, the thickness of the outer ring of the transition ring piece 03 is consistent with the thickness of the first ring piece 01, the steam sealing piece is a martensitic stainless steel sealing piece, and the ring surface on one side of the steam sealing pi...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 1 to Figure 3 Note that the annulus of the small ring 02, the annulus of the transition ring 03 and the annulus of the large ring 01 corresponding to the annulus on the other side of the steam seal in this embodiment are all cold-rolled annulus.

[0014] The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination Figure 1 to Figure 3 Note that the chamfer 04 of the small ring piece 02 in this embodiment is a 45° chamfer. The 45° chamfer is a common chamfer in machining, which is easy to manufacture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com