Vacuum heat insulation tube

A technology of vacuum heat insulation and vacuum nozzles, which is applied in the direction of protecting pipelines, pipe components, and pipeline protection through heat insulation, which can solve the problems of not being able to better meet the needs of actual use, not improving the service life, and affecting the normal operation of the station, etc. problems, to achieve the effect of improving operating costs and quality, improving production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

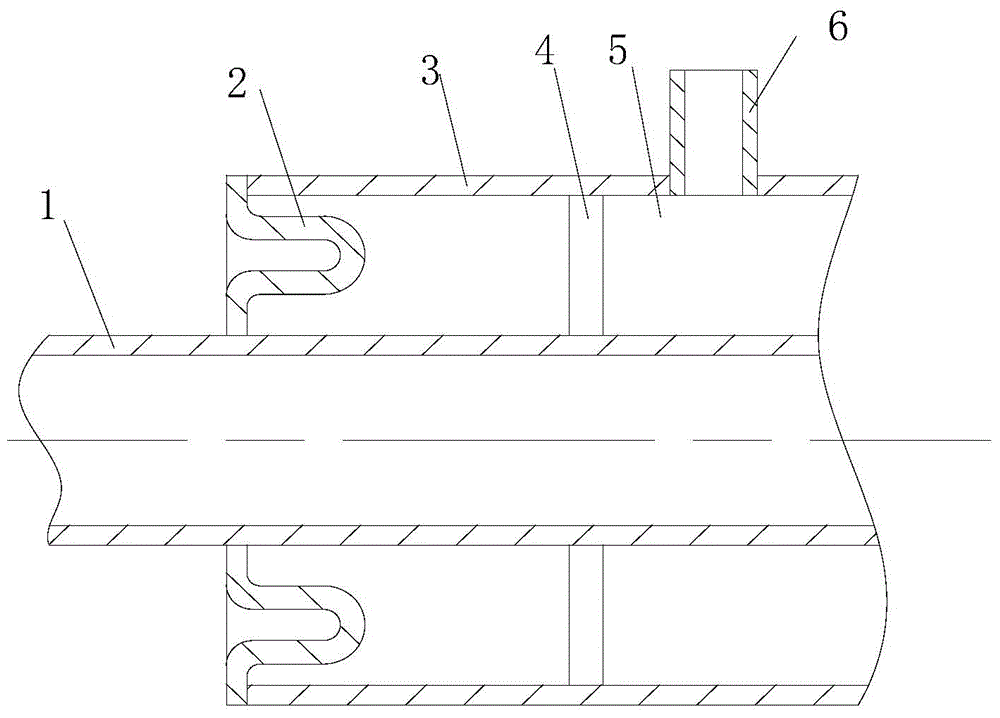

[0012] Such as figure 1 with figure 2 As shown, the vacuum insulated pipe of the present invention includes an inner pipe 1 and an outer pipe 3, the inner pipe 1 and the outer pipe 3 are coaxial, an inner pipe support 4 is provided between the inner pipe 1 and the outer pipe 3, and the outer wall of the inner pipe 1 has The outer tube 3 is welded with a vacuum nozzle 6 perpendicular to it, and the vacuum nozzle 6 is used to draw a high vacuum. Generally, the vacuuming time is about 8 days, and the vacuum leak is detected by a helium mass spectrometer leak detector.

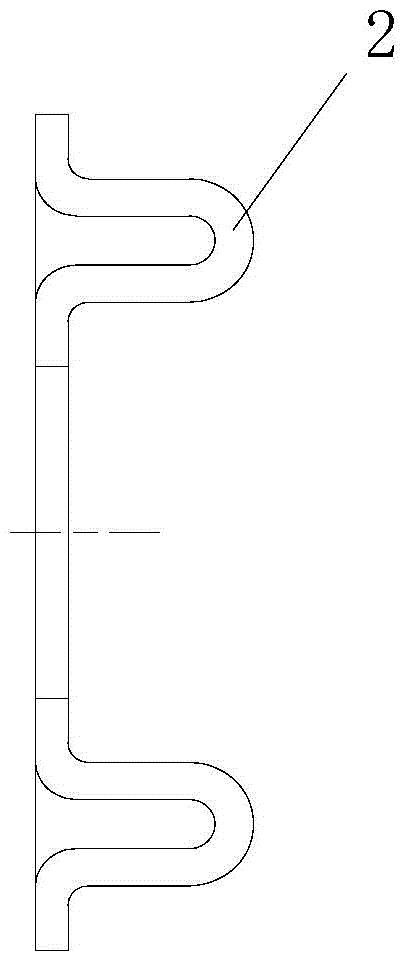

[0013] The vacuum insulation tube end plate 2 is vertically welded between the inner tube 1 and the outer tube 3 . A groove is arranged inside the end plate 2 of the vacuum heat insulating tube. The vacuum insulation tube end plate 2 is U-shaped. The inner tube 1, the outer tube 3, and the vacuum insulation tube end plate 2 are made of austenitic stainless steel. The end plate 2 of the vacuum heat insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com