Precision test method of two-freedom-degree tracking angle measurement device

An inspection method and technology with degrees of freedom, applied in the directions of measuring devices, measuring angles, surveying and mapping, and navigation, etc., can solve problems such as hindering the factory efficiency of batch production devices, high requirements for use conditions, and insufficient inspection equipment accuracy. The effect of improving measurement accuracy and simple detection principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

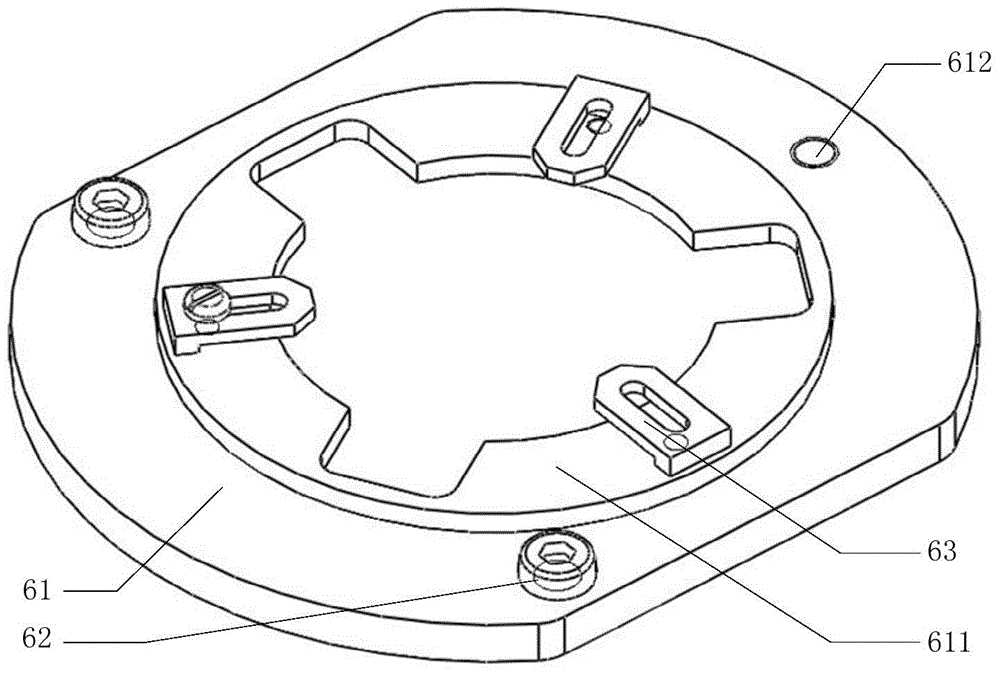

[0037] Combined with Figure 6- Figure 8 , the method according to the present invention comprises the following steps:

[0038] (1) Azimuth angle measurement accuracy inspection

[0039] S11 , fixing the two-degree-of-freedom tracking goniometric device 1 on the two-axis rate-position turntable 2 .

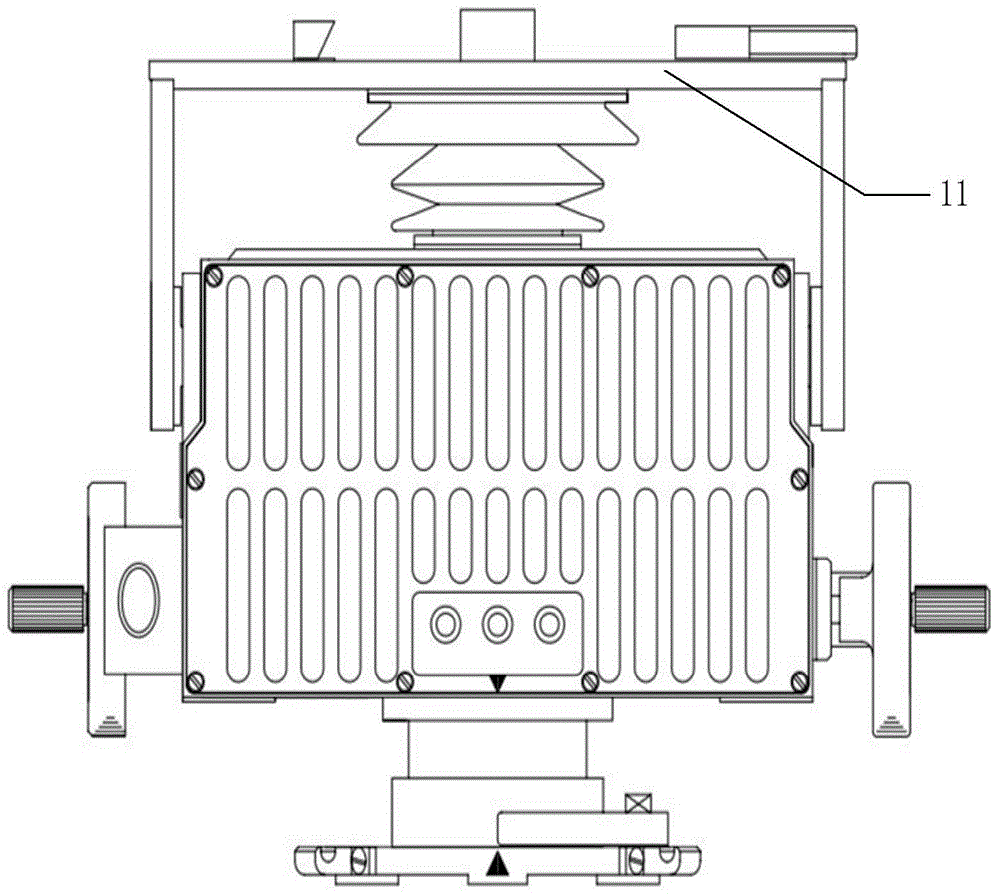

[0040] In this step, the structure of the two-degree-of-freedom tracking angle measuring device is known, such as a theodolite. figure 1 It is a simplified structural diagram of a two-degree-of-freedom tracking angle measuring device.

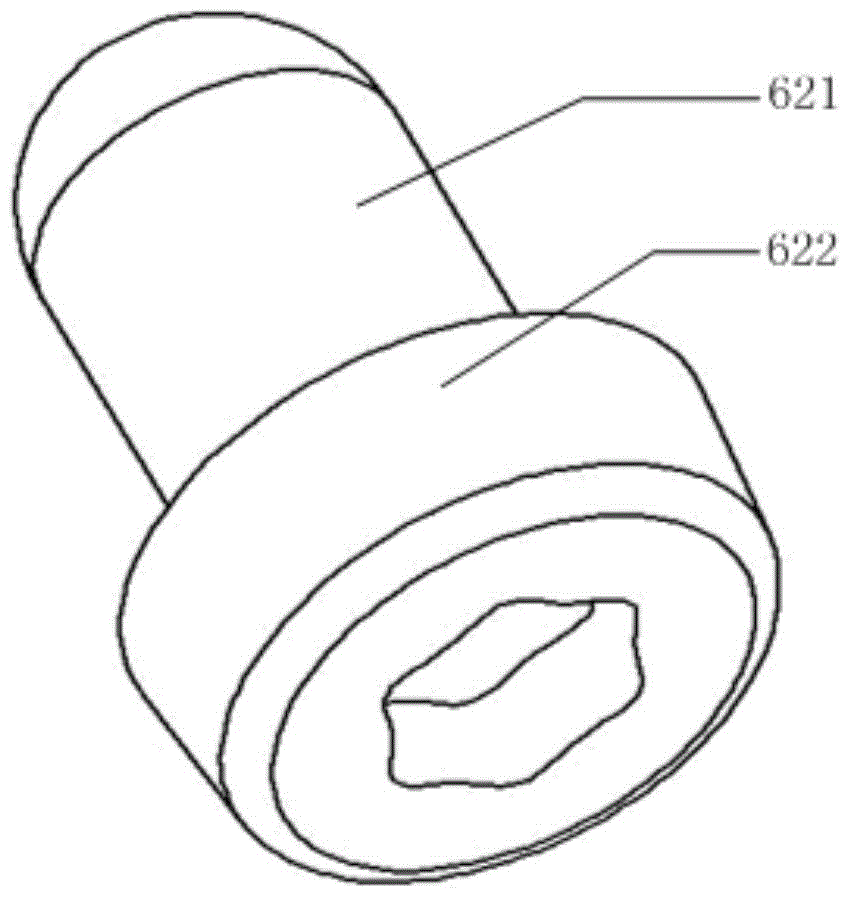

[0041] In practice, the two-degree-of-freedom tracking goniometer device 1 can be fixed on the dual-axis rate-position turntable 2 in various ways, for example, by using pads to support the two-degree-of-freedom tracking goniometer device 1, and then using a pressure plate and screws to fix the two-degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com