Fatigue test method and fixture thereof of rubber bushing

A technology for rubber bushing and fatigue testing, which is applied in the testing of vehicles, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems of inaccurate and large differences in bench tests, and achieve short test periods , high accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

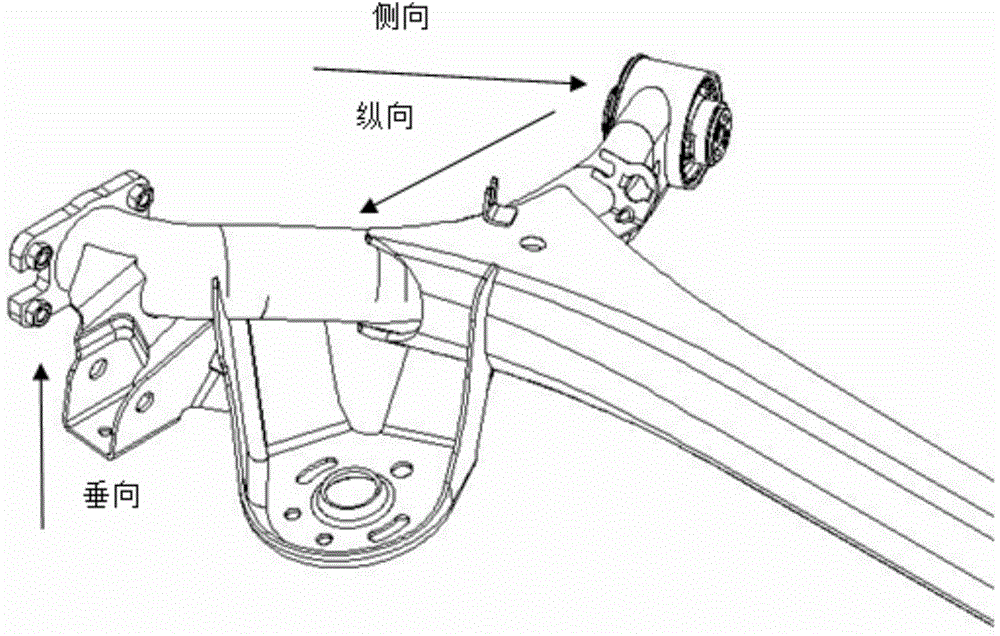

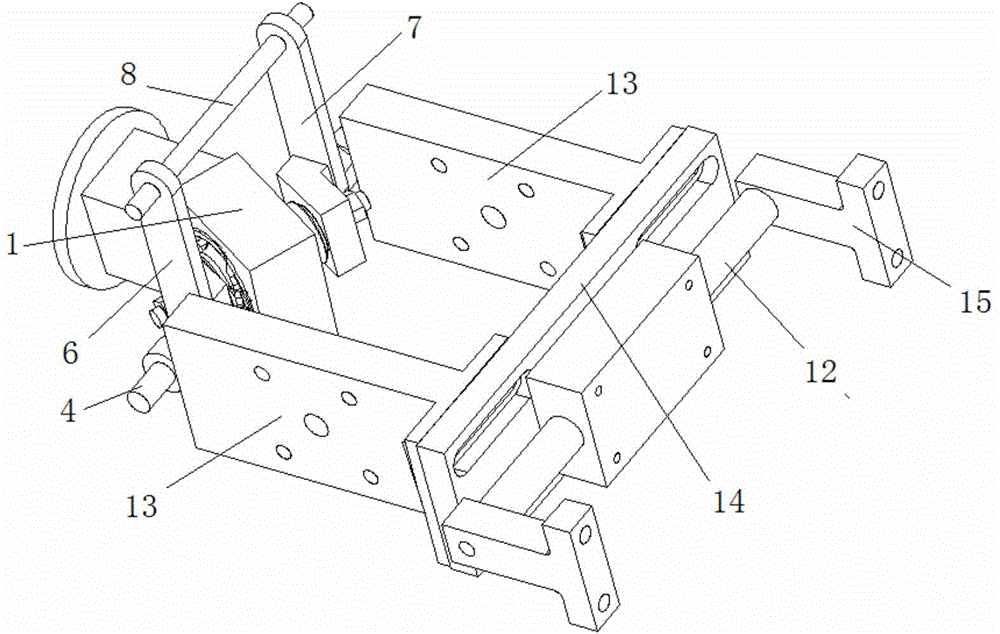

[0027] Embodiment, taking the torsion beam bushing of an automobile as an example, the torsion beam bushing in a real vehicle is as follows: figure 1 As shown, the main loads are longitudinal force, lateral force, and vertical displacement. The above three loads are collected by the test site, and then the loads are filtered, deburred, etc., and the strain signals are converted into force value target signals and Displacement target signal.

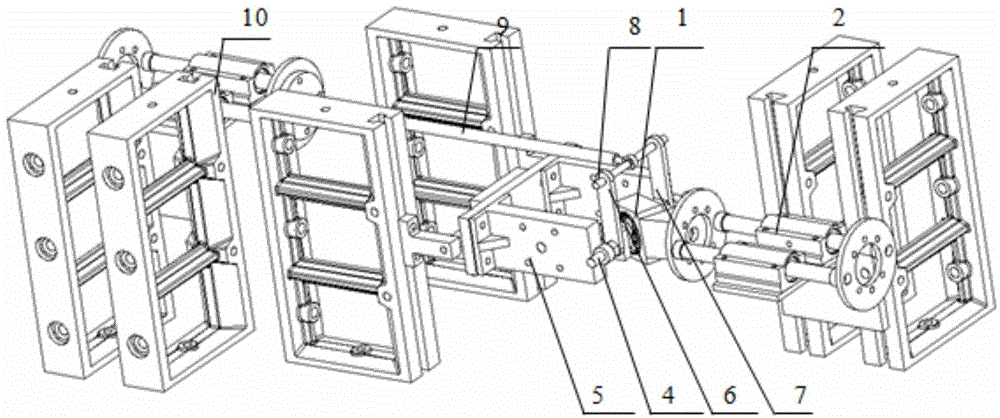

[0028] The force value target signal and the displacement target signal are respectively iteratively calculated to obtain the force value drive signal and the displacement drive signal. The iterative operation is specifically to obtain the initial force value driving signal and the initial displacement driving signal according to the force value target signal, displacement target signal, system frequency response inverse function and iteration factor, specifically, through the force value target signal or displacement drive signal × frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com