Tire lateral inclination and lateral deviation steady-state lateral force characteristic modeling method based on nonlinear superposition

A modeling method and lateral force technology, applied in the field of tire dynamics, can solve the problems of ambiguous physical meaning of model parameters and low model prediction ability, and achieve the effect of high model accuracy, strong prediction ability, and satisfying theoretical boundary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

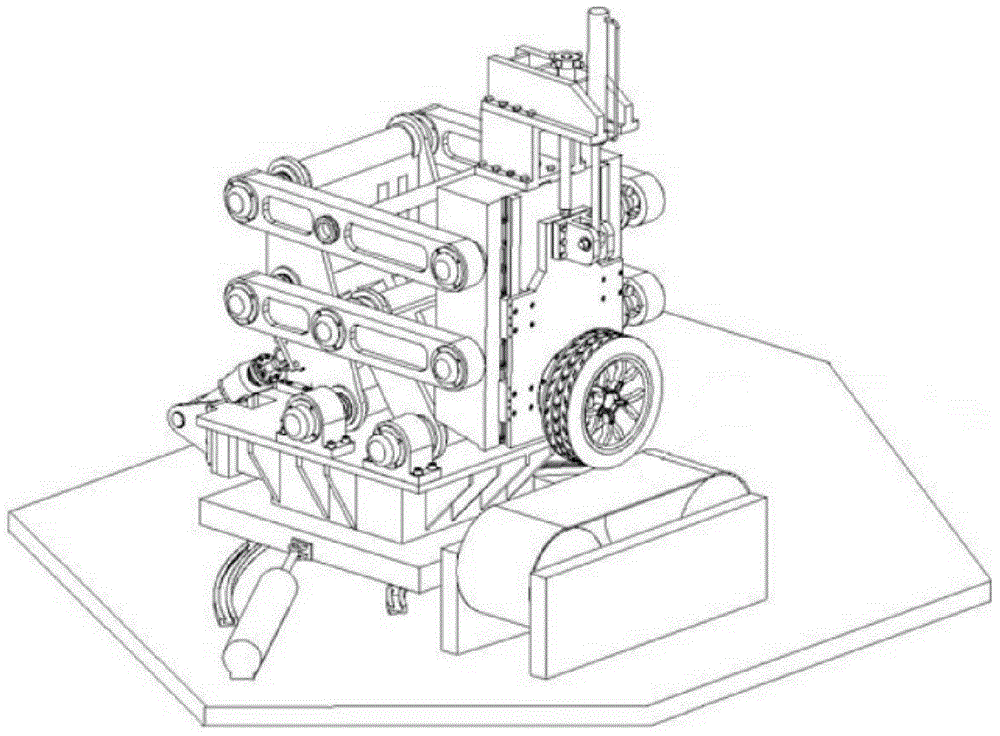

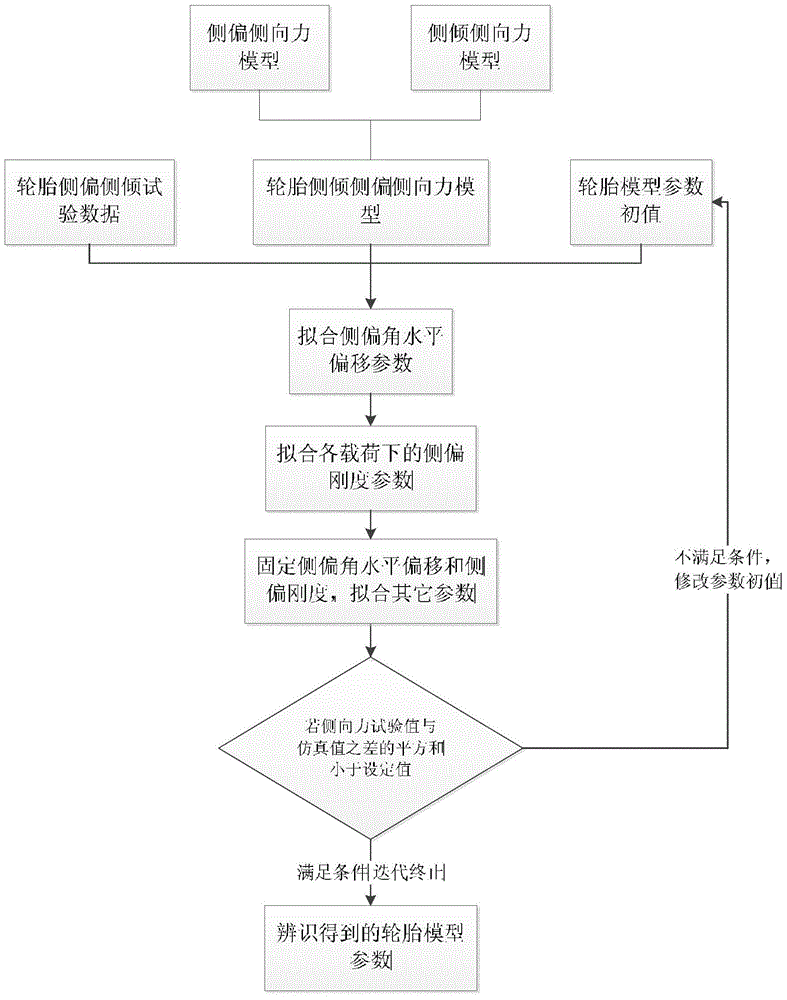

[0071] The present invention will be further described below in conjunction with the accompanying drawings. The tires used in the verification of this method are General P215 / 70R1699S tires with a tire pressure of 262kPa. figure 1 The tire mechanical characteristics test bench test shown in the figure obtained the test data under the tire roll and yaw condition, using the invented tire roll and roll yaw steady-state lateral force model based on nonlinear superposition, and using the curve fitting technology to identify the tire The parameters of the model. Specific steps are as follows:

[0072] Step 1: Install General P215 / 70R16 99S tires on such as figure 1 On the tire mechanical characteristic test bench shown in Table 1, complete the steady-state mechanical characteristic test under the tire roll and yaw condition according to the test requirements shown in Table 1, and record the test data. The test data include tire roll angle, side slip angle, vertical load , tire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com