Automatic iron ore grade detection system and method

An automatic detection, iron ore technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of increasing detection work time, prolonging mining work time, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with examples.

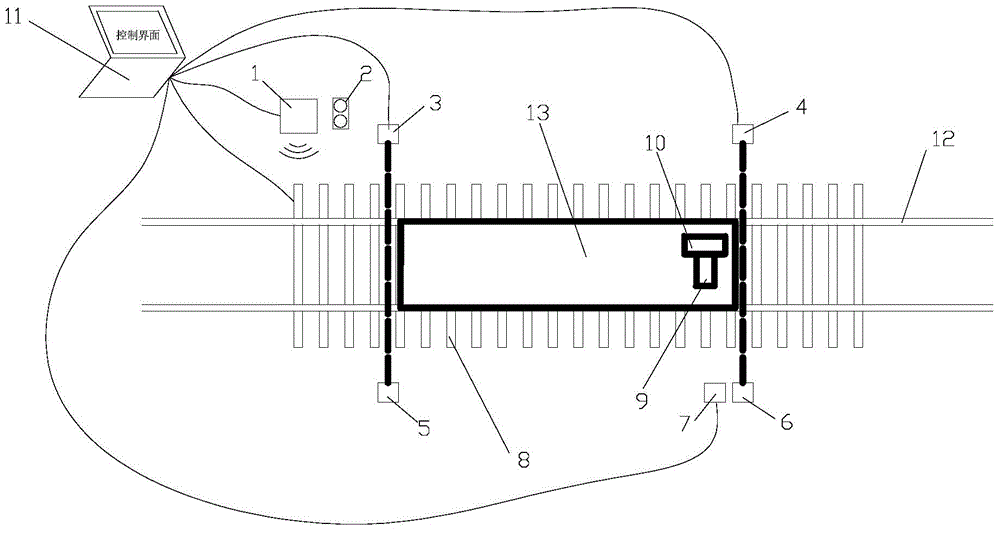

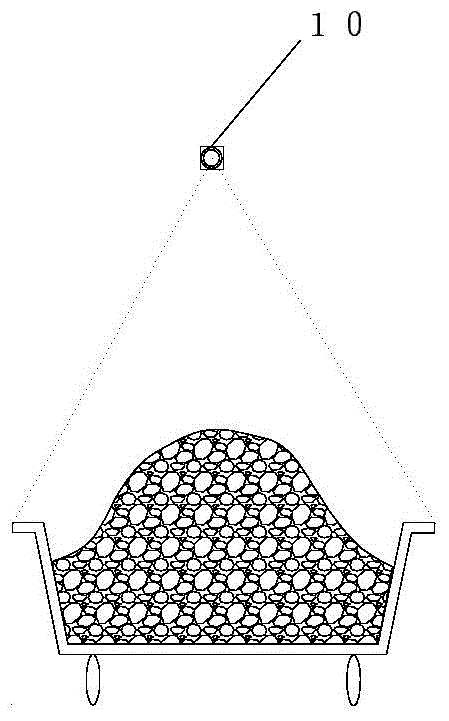

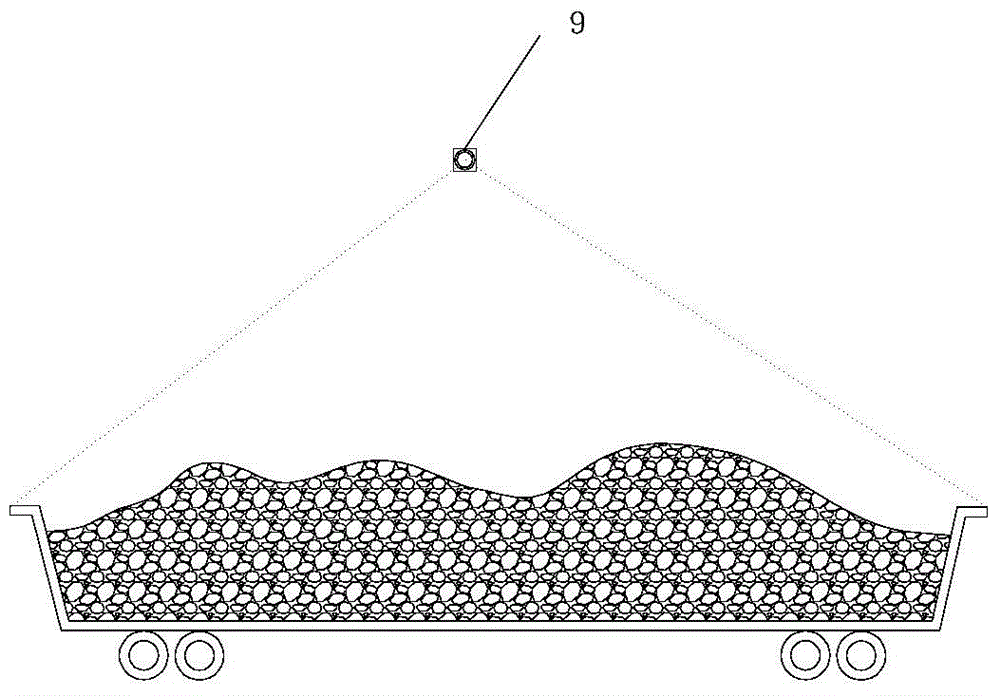

[0037]An automatic iron ore grade detection system is characterized in that it includes an RFID card reader 1 installed at the entrance of the measurement area, a red and green indicator light 2, an entrance photoelectric switch 3 and an entrance reflection plate 5; a dynamic Track scale 8, a vertical two-dimensional laser scanner 10 whose scanning direction is perpendicular to the track and a parallel two-dimensional laser scanner 9 whose scanning direction is parallel to the track are installed at the exit boundary of the measuring area above the measuring area, installed in the network of the measuring area Camera 7, exit photoelectric switch 4 and exit reflector 6; described entrance photoelectric switch 3 and entrance reflector 5 are respectively on both sides of track 12, RFID card reader 1, red and green indicator light 2, entrance photoelectric switch 3, vertical The electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com