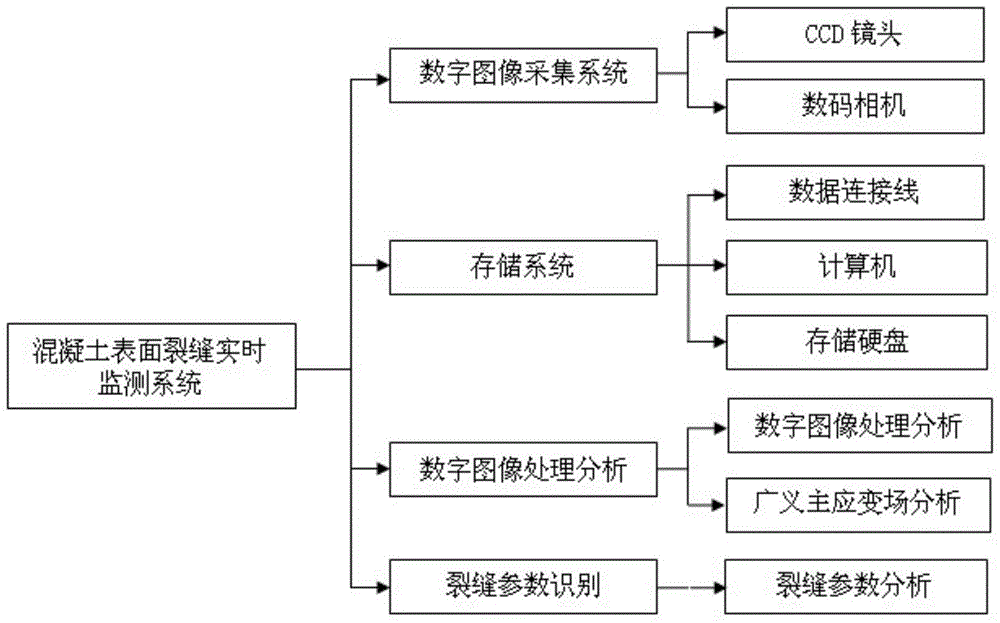

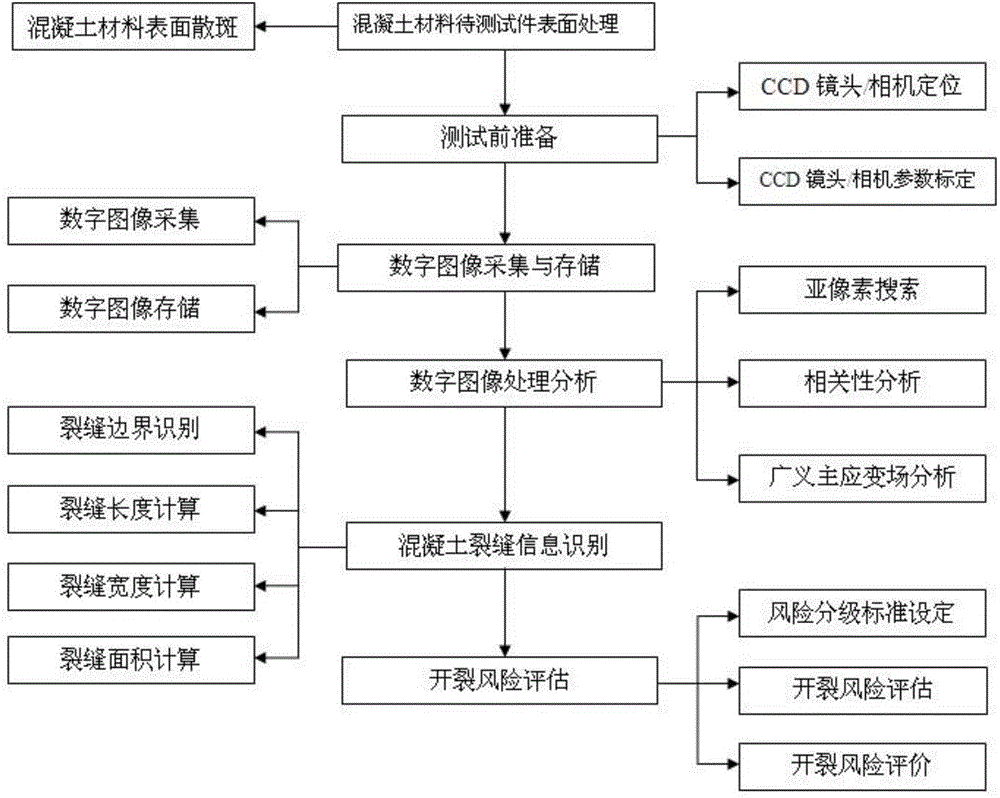

Concrete surface crack real-time monitoring system and cracking risk dynamic assessment method

A real-time monitoring system and concrete surface technology, applied in the direction of measuring devices, optical testing flaws/defects, image data processing, etc., can solve problems such as large errors, prone to cracks and background misjudgment, and inability to assess the risk of concrete structure cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

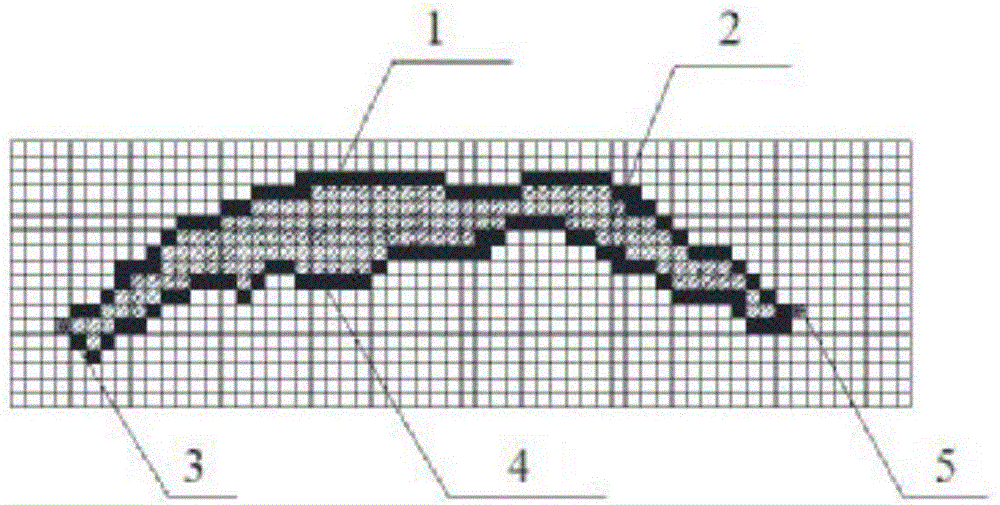

[0252] In reinforced concrete structures, steel corrosion is the main factor leading to concrete cracking. The cracking process of corroded reinforced concrete is simulated, the characteristic parameters of concrete cracks are monitored in real time by the invention, and the cracking risk of concrete is dynamically evaluated.

[0253] The mixing ratio of cement, water, fine aggregate and coarse aggregate in the concrete is 1:0.53:2:3. The cement is P·O52.5 grade ordinary Portland cement produced by Hubei Huaxin Cement Factory; the fine aggregate is river Sand, fineness modulus is 2.64; coarse aggregate is gravel, 5-20mm continuous gradation; water is tap water. The compressive strength of concrete 28d is 46.3MPa. The longitudinal reinforcement of the concrete beam adopts a Φ10HPB235 steel bar, and the stirrup is Φ6100, The size of the specimen is 100mm×100mm×400mm, and the reinforcement of the specimen is as follows: Figure 4 and Figure 5 shown.

[0254] The speckle image o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com