Adaptive data driving fault diagnosis method and device in complex refining process

A data-driven, fault-diagnosing technology, applied in instrumentation, electrical testing/monitoring, control/regulation systems, etc., to solve problems such as inability to apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

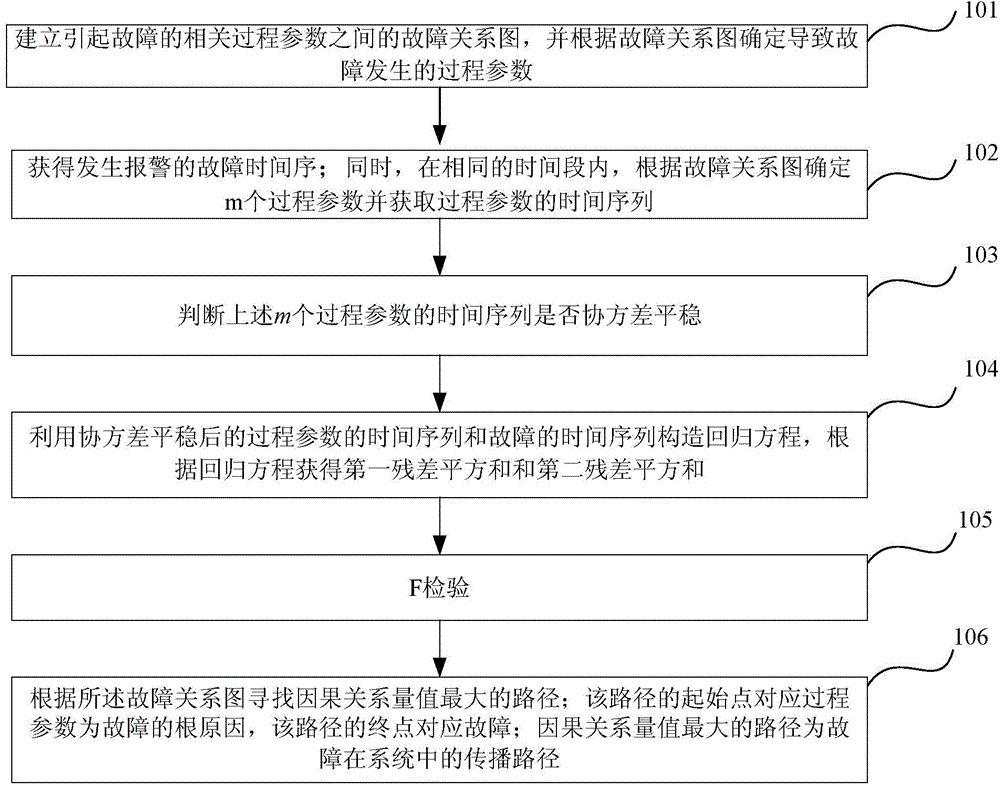

Method used

Image

Examples

Embodiment

[0083] According to the calculation process and calculation steps of Granger causality test, the common refinery process - the initial distillation column in atmospheric and vacuum distillation is taken as the research object, and the device fault diagnosis is carried out by using the simulation data.

[0084] This technical solution uses MATLAB to program the Granger causality test, and takes the failure data of the initial distillation column feed reduction as input.

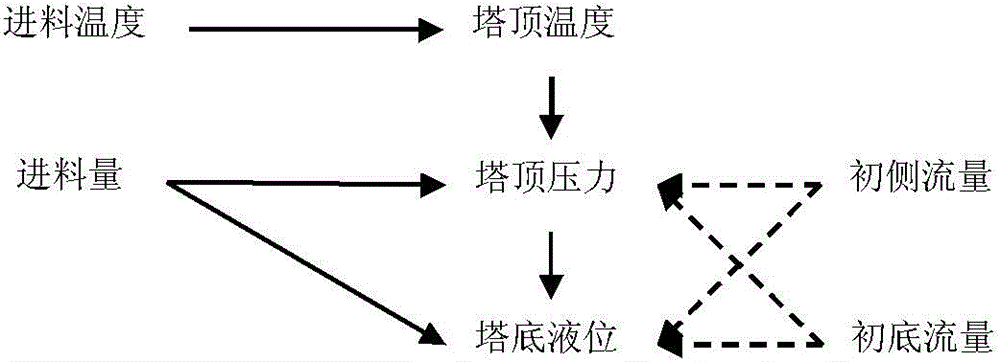

[0085] In the primary distillation tower, the main process parameters are primary distillation tower feed volume and temperature, primary distillation tower top pressure, primary distillation tower top temperature, primary distillation tower bottom liquid level, primary bottom and primary side flow. According to the knowledge of chemical process, the interaction relationship between various process parameters can be known, such as image 3 Shown is the process parameter relationship diagram of this embodiment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com