Determination method of regenerative work ratio and regenerative gain rate when non-reheat unit has heater heat dissipation loss

A technology of non-reheat unit and regenerative work ratio, which is applied in the field of soft measurement and can solve problems such as failure and heat dissipation loss of heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

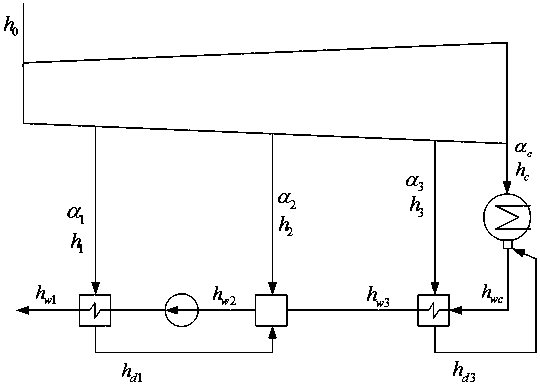

[0085] A method for measuring the regenerative work ratio and regenerative gain rate when a non-reheat unit has heater heat dissipation loss, and its calculation model is aimed at a non-reheat unit with three-stage regen. The steam turbine consists of a cylinder, and its three-stage extraction steam is numbered as the first, second and third extraction steam in sequence, and is connected to the first, second and third heaters respectively. The heater is a surface heater, and its water discharges to the second-stage heater, the second-stage heater is a hybrid heater, and the third-stage heater is a surface heater, and its water discharges to the hot well of the condenser.

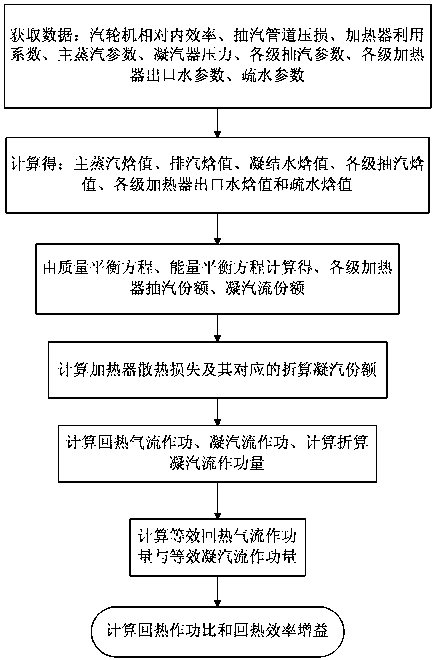

[0086] The measurement steps are as follows,

[0087] Step 1: Calculation of steam-water parameters in thermal system

[0088] Step 1.1: Take the relative internal efficiency η of the steam turbine under THA (Turbine Heat Acceptance, heat consumption guaranteed working condition) ri , The pressure loss rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com