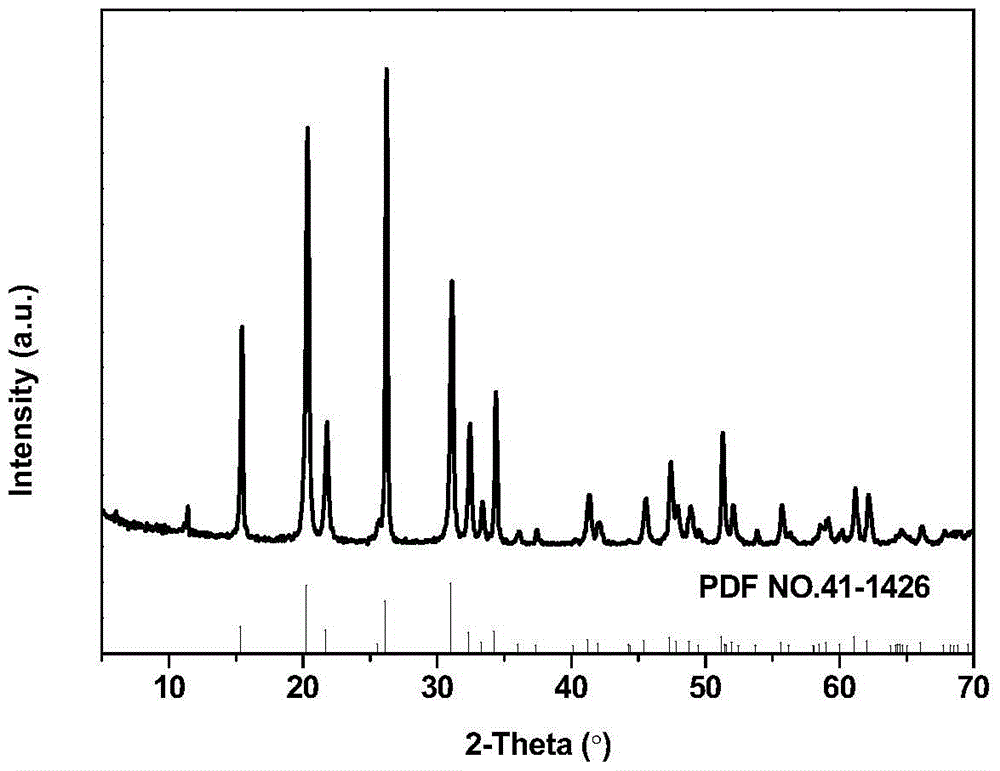

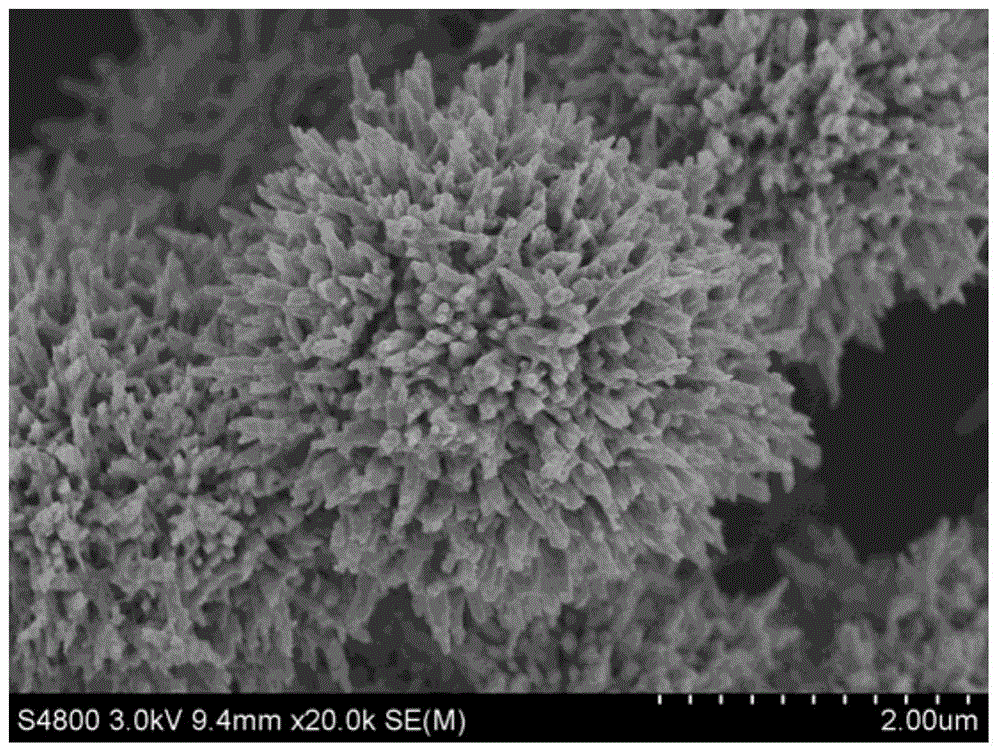

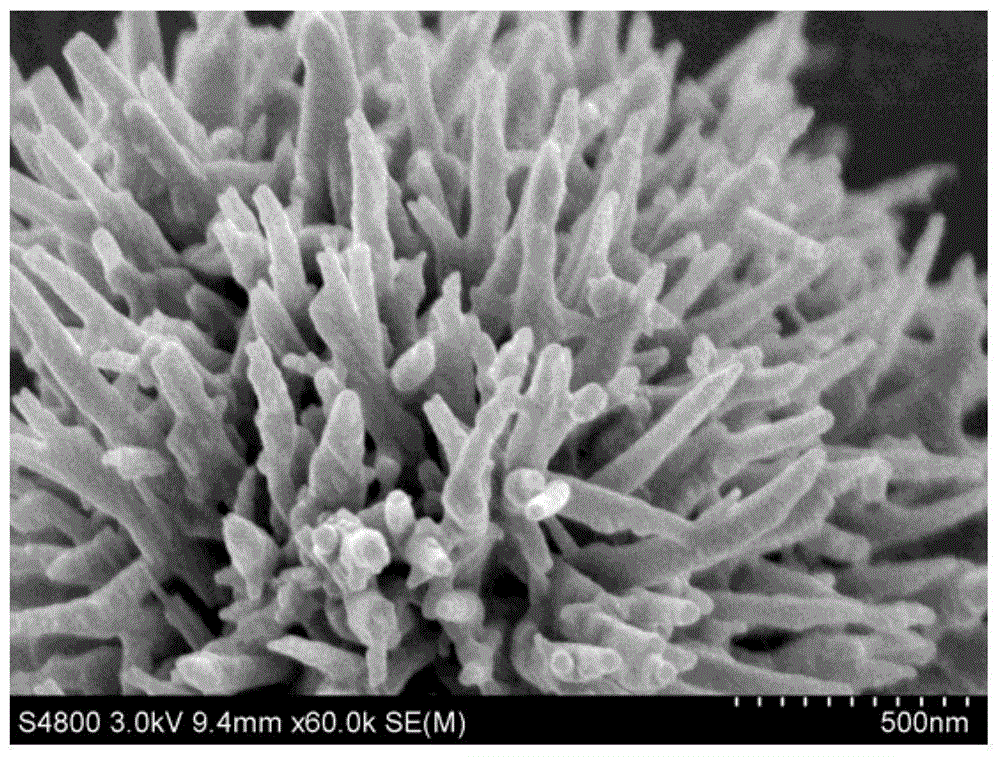

A self-assembled flower spherical lithium-ion battery positive electrode material v 2 o 5 preparation method

A technology of lithium ion battery and positive electrode material is applied in the field of preparation of positive electrode material V2O5 of self-assembled flower ball-shaped lithium ion battery, which can solve the problems of high cost of vanadium acetylacetonate, unfavorable large-scale industrialization and the like, achieve uniform morphology and improve electrochemical performance. Performance, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) The analytical pure ammonium metavanadate (NH 4 VO 3 ) Dissolve in ethylene glycol, then add deionized water to prepare 100mL mixed solution, the volume ratio of ethylene glycol and deionized water is 1:5, magnetic stirring for 1h to make ammonium metavanadate dissolve evenly, prepare NH 4 + The concentration of NH is 0.30mol / L 4 VO 3 Solution, marked as A solution;

[0025] 2) Use 6mol·L -1 Adjust the pH value of the A solution with the diluted hydrochloric acid to 2.0, and then heat the reaction for 2h under the water bath condition of 90℃ to obtain a suspension;

[0026] 3) Centrifugally separate the obtained suspension to obtain a powder product, and then soak the powder product in deionized water for 10 minutes, wash 5 times, and then soak in absolute ethanol for 10 minutes and wash 5 times, and then place it in an oven at 60 Dry at ℃ for 10h to obtain the precursor;

[0027] 4) Put the precursor in a crucible, put it into a muffle furnace and heat it at 350°C for 1 ho...

Embodiment 2

[0030] 1) The analytical pure ammonium metavanadate (NH 4 VO 3 ) Dissolve in ethylene glycol, then add deionized water to prepare 100mL mixed solution, the volume ratio of ethylene glycol and deionized water is 1:4, magnetic stirring for 0.5h to dissolve ammonium metavanadate evenly, and prepare NH 4 + The concentration is 0.25mol / L NH 4 VO 3 Solution, marked as A solution;

[0031] 2) Use 2mol·L -1 Adjust the pH value of the A solution with the diluted hydrochloric acid to 3.0, and then conduct a heating reaction for 5 hours under the condition of a water bath at 60°C to obtain a suspension;

[0032] 3) Centrifugally separate the obtained suspension to obtain a powder product, and then soak the powder product in deionized water for 10 minutes, wash 5 times, and then soak in absolute ethanol for 10 minutes and wash 5 times, and then place it in an oven at 60 Dry at ℃ for 10h to obtain the precursor;

[0033] 4) Put the precursor in a crucible, put it into a muffle furnace and heat it...

Embodiment 3

[0035] 1) The analytical pure ammonium metavanadate (NH 4 VO 3 ) Dissolve in ethylene glycol, then add deionized water to prepare 100mL mixed solution, the volume ratio of ethylene glycol to deionized water is 1:3, magnetic stirring for 0.5h to make ammonium metavanadate dissolve uniformly, and prepare NH 4 + The concentration of NH is 0.20mol / L 4 VO 3 Solution, marked as A solution;

[0036] 2) Use 11mol·L -1 Adjust the pH value of the A solution with the diluted hydrochloric acid to 4, and then heat the reaction for 3h under the condition of a water bath at 70℃ to obtain a suspension;

[0037] 3) Centrifugally separate the obtained suspension to obtain a powder product, and then soak the powder product in deionized water for 10 minutes, wash 5 times, and then soak in absolute ethanol for 10 minutes and wash 5 times, and then place it in an oven at 60 Dry for 10h at ℃, which is the precursor;

[0038] 4) Put the precursor in a crucible, put it into a muffle furnace and heat it at 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com