Fuel cell humidifier and proton-exchange membrane fuel cell using same

A technology of proton exchange membrane and fuel cell, which is applied in the direction of fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve the problem of high manufacturing cost and use cost, unfavorable commercialization and application of fuel cells, and inconvenience of fuel cell power generation. Stack manufacturing and maintenance issues to achieve the effect of reducing manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

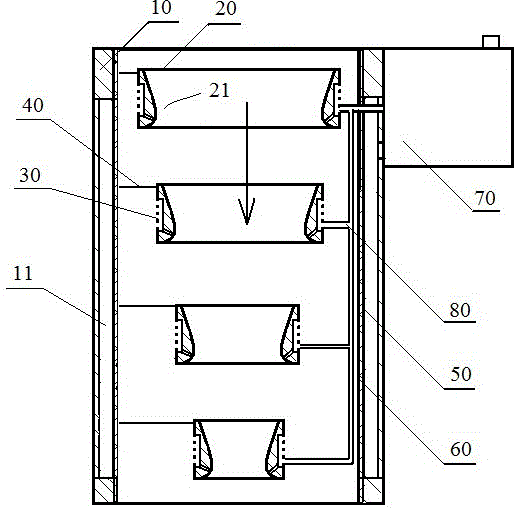

[0019] An embodiment of the fuel cell humidifier in the present invention is Figure 1~Figure 2 As shown, it includes a humidifying cylinder 10 for air to pass through, a water pool 70 as a water source, and four mouthpiece rings 20 fixedly arranged in the humidifying cylinder 10 through brackets 40 .

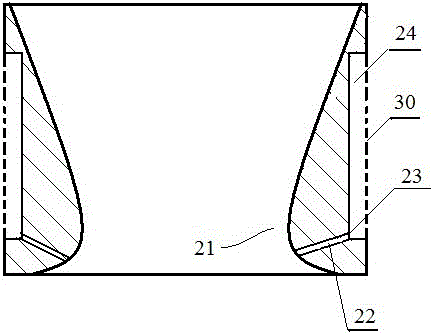

[0020] The four bellows rings 20 are arranged coaxially with the humidifying cylinder 10, each bellows ring 20 is arranged at intervals along the axial direction, and the radial dimensions of adjacent bellows rings 20 decrease sequentially along the gas flow direction. Each bellows ring 20 adopts a ring structure, and there is a constricted part 21 in the ring body, which is similar to a throat, so it is called a "loudmouth ring". The inner diameter of the constriction 21 is smaller than the inner diameter of the bellows ring 20 at its upstream and downstream positions, so that when the air flow flows through the ring, the flow velocity can suddenly increase at the constriction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com