Telescopic piezoelectric vibration generator

A piezoelectric vibration and generator technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of weak power generation capacity, poor environmental adaptability, and reliability Low-level problems, to achieve the effect of strong power generation capacity, strong adaptability to vibration direction, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

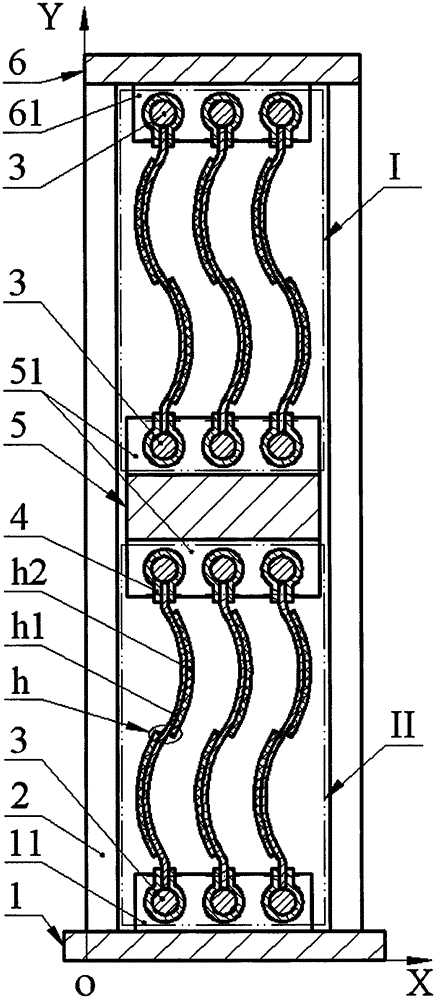

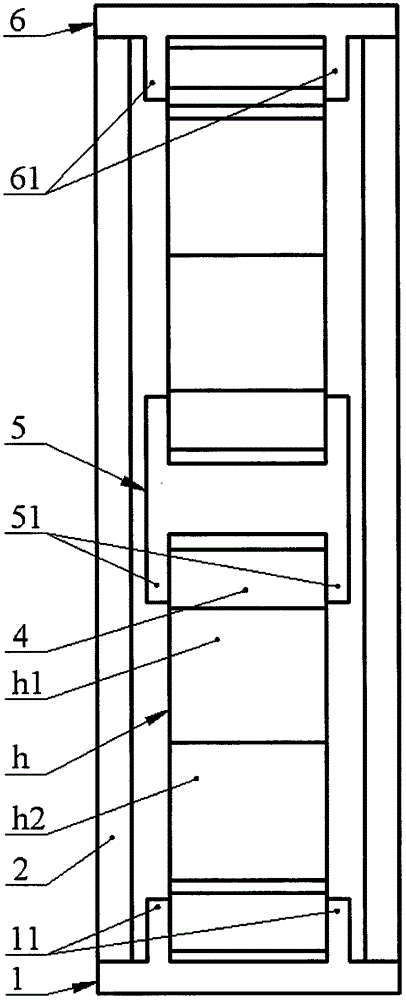

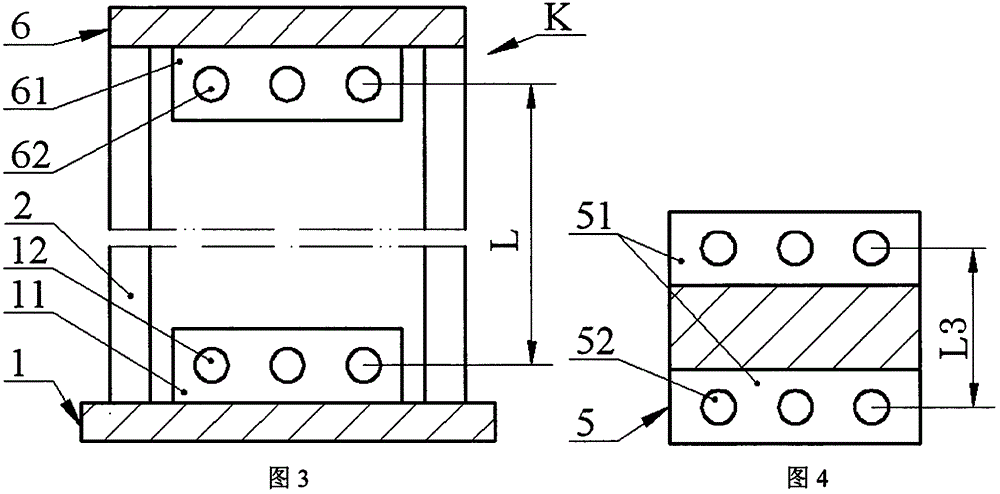

[0012] The bottom plate 1 and the top plate 6 are welded with the column 2 to form a frame K. The bottom plate 1 is provided with two bottom side ears 11 with pin holes 12, and the top plate 6 is provided with two top side ears 61 with pin holes 62; Two middle side ears 51 with pin holes 52 are arranged on the upper and lower sides of 5; the metal sheet h1 with arc-shaped protrusions and the piezoelectric sheet h2 bonded to the arc-shaped protrusions form piezoelectric vibrator h, and the piezoelectric vibrator The vibrator h constitutes the transducer H through the split pin sleeve 4 riveted to both ends of the metal sheet h1; the pin sleeve 4 at one end of the group I transducer H is set on the pin shaft 3 riveted in the pin hole 62 of the top ear 61 1. The pin sleeve 4 at the other end is set on the pin shaft 3 in the pin hole 52 riveted on the middle side ear 51; the pin sleeve 4 at one end of the II group transducer H is set on the pin in the pin hole 12 riveted on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com