First tread wedge joint plate

A joint and metatarsal wedge technology, applied in the field of medical devices, can solve problems such as low fusion rate, poor fixation stability, and increased incidence of osteoarthritis, and achieve the effect of increasing fusion rate, reducing stimulation, and facilitating early passive exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

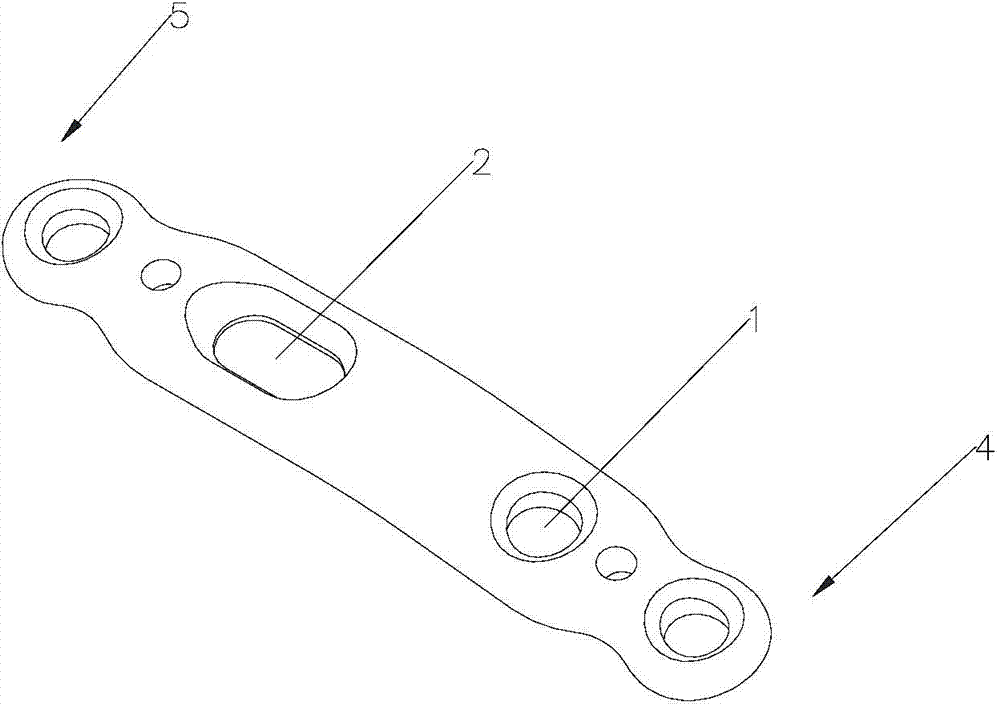

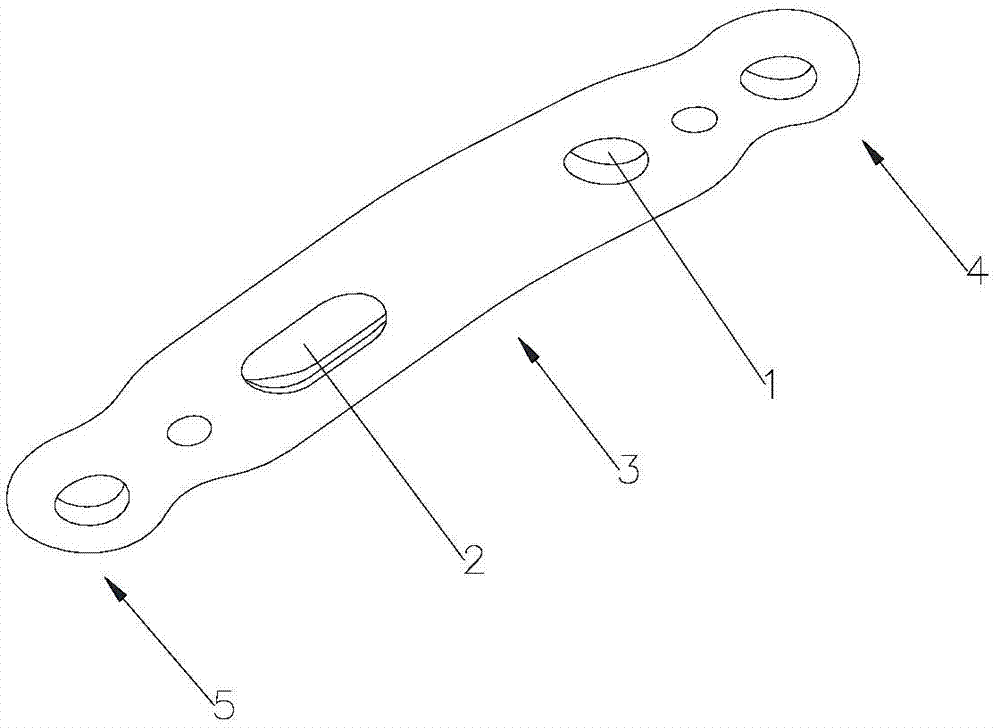

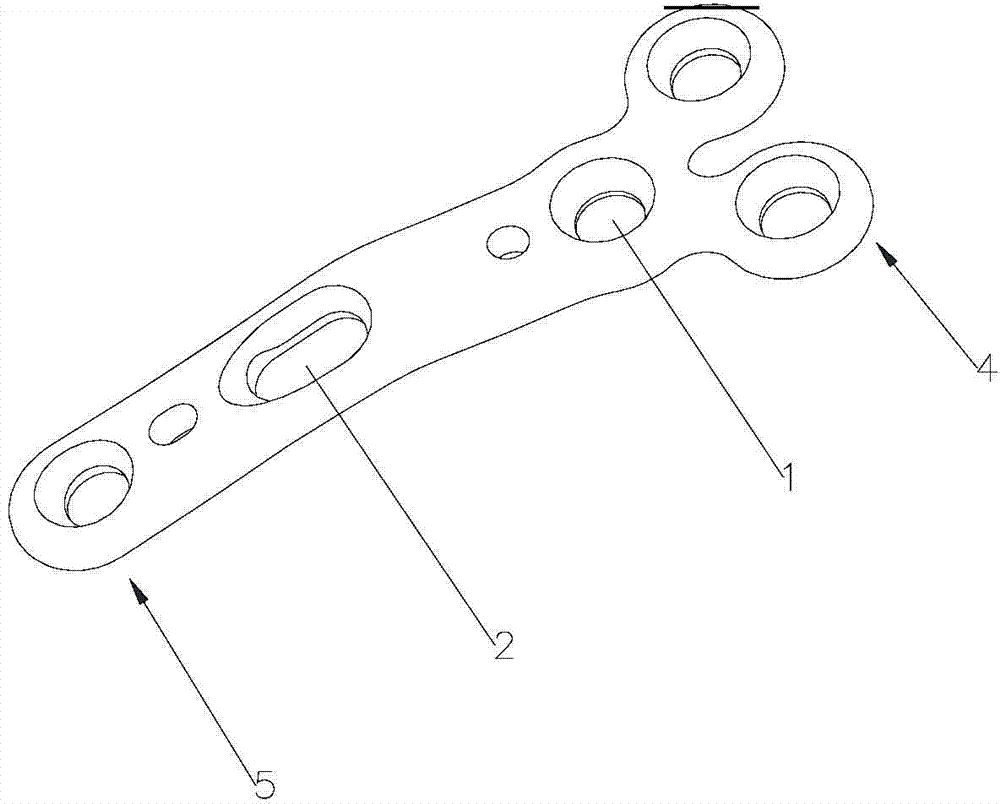

[0024] Such as figure 1 , figure 2 As shown, a first metatarsal wedge joint plate is a stainless steel plate with a thickness of 1.8mm, including a proximal end 4 and a distal end 5, the proximal end 4 is provided with two fixing holes 1, and the distal end 5 is provided with a fixing hole 1. There is also a sliding hole 2 on the first metatarsal cuneiform joint plate to facilitate the pressure between the bone blocks when the first metatarsal cuneiform joint is fused. The position of the sliding hole 2 is the same as when the joint plate is fixed on the first metatarsal bone and the medial cuneiform bone The position of the first metatarsal cuneiform joint corresponds to that of the first metatarsal cuneiform joint. The sliding hole 2 is located at the distal end 5 of the first metatarsal cuneiform joint. The surface morphology of the metatarsal bone and the medial cuneiform bone match, that is, the proximal end of the first metatarsal cuneiform joint plate 4 matches the sh...

Embodiment 2

[0027] A first metatarsal wedge joint plate, which is a pure titanium plate with a thickness of 1.8 mm, comprising a proximal end 4 of the first metatarsal wedge joint plate and a distal end 5 of the first metatarsal wedge joint plate, and a proximal end 4 of the first metatarsal wedge joint plate There are three fixing holes 1, which are distributed in the shape of a character. The distal end 5 of the first metatarsal cuneiform joint plate is provided with a fixing hole 1, and the first metatarsal cuneiform joint plate is also provided with a joint between the bone blocks to facilitate the fusion of the first metatarsal cuneiform joint. Pressed sliding hole 2, the position of the sliding hole 2 corresponds to the position of the first metatarsal wedge joint when the first metatarsal wedge joint plate is fixed on the first metatarsal bone and the medial cuneiform bone, and the sliding hole 2 is located on the first metatarsal wedge joint plate 5 at the distal end; the spatial g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com