Injection type positive-negative-pressure foam proportionally mixing system of fire-extinguishing foam tanker

A foam fire truck and proportional mixing technology, which is applied in fire rescue and other directions, can solve the problems of reducing the accuracy of the mixing ratio, the maximum suction capacity, affecting the foam suction volume, consuming the output pressure of the foam pump, etc., and achieving the improvement of overall performance and adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

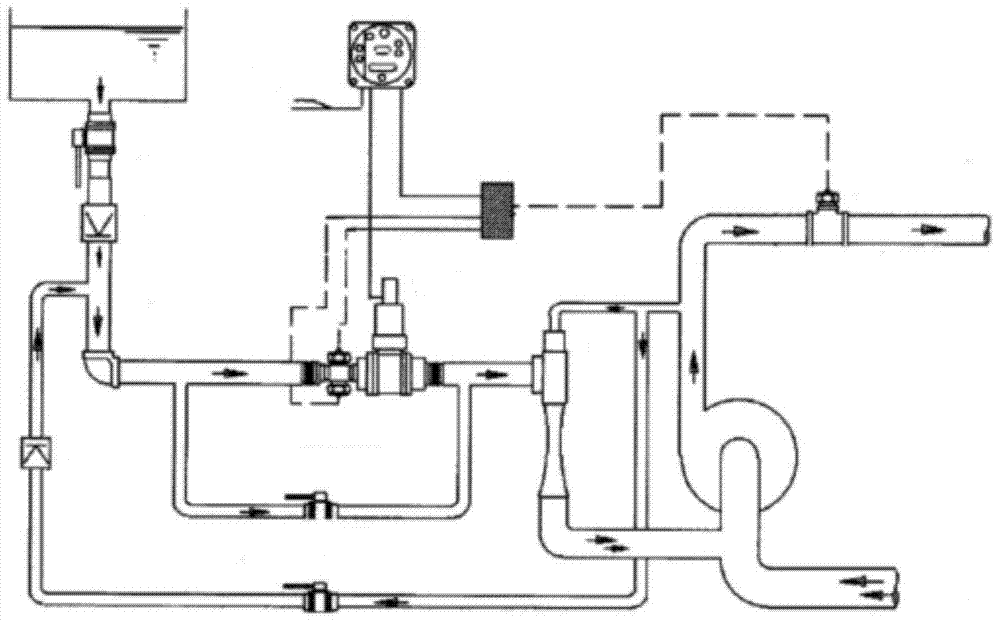

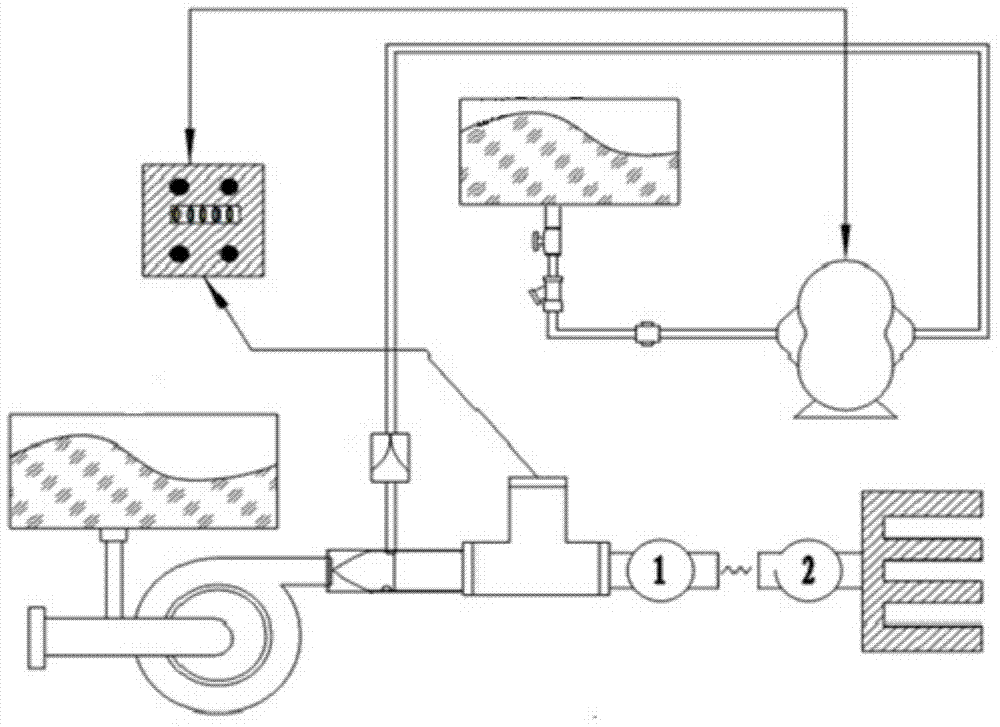

Method used

Image

Examples

Embodiment Construction

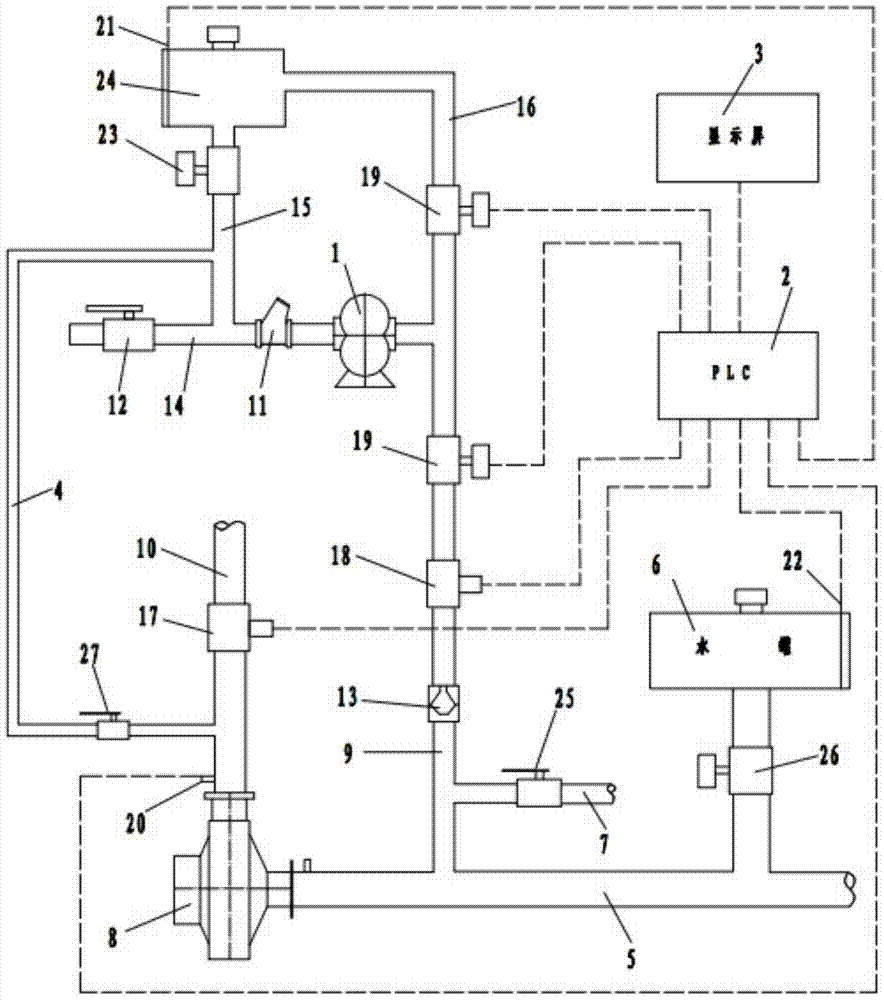

[0032] Such as image 3 Shown is a foam fire engine injection type positive and negative pressure foam proportional mixing system, the mixing system is connected to the external water inlet pipeline 5 through the foam pump outlet pipeline 9, and the end of the external water inlet pipeline 5 is connected to the water inlet of the pressure water pump 8, The water outlet of the pressure water pump 8 is connected to the water outlet pipeline 10 . This invention is different from the traditional positive pressure system which connects the foam injection port to the water outlet, but creatively connects the main foam inlet to the water inlet pipeline, which can overcome the problem that the foam stock solution cannot be injected when the water pump outlet pressure of the positive pressure system exceeds 12bar .

[0033]Foam tank 24 is provided on the foam proportional mixing system in positive and negative pressure state, and foam tank 24 is connected to the inlet of foam pump 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com