Spin-on double-layer mixed dust bag and its manufacturing process

The technology of dust removal cloth and cloth bag is applied in the field of rotary double-layer mixed dust removal cloth bag and its manufacturing process. , The filtering effect is strengthened, and the production and installation and disassembly are convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

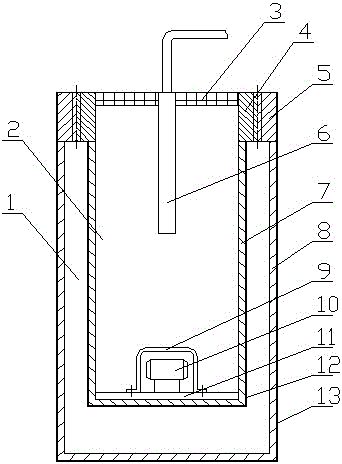

[0024] Such as figure 1 As shown, a screw-on double-layer mixed dust bag is composed of an outer bag 1 and an inner bag 2 .

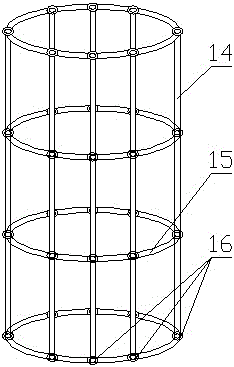

[0025] The outer bag 1 includes an outer dust cloth 13, an outer frame 8, and an outer retaining ring 5. The outer dust cloth 13 is made of materials such as polyester, polypropylene or fiberglass, and is sewn into a bag shape and is fitted on the outer frame 8. The outer frame 8 top is welded or is installed with an outer retaining ring 5 with screws, and the inner side of the outer retaining ring 5 is machined with internal threads.

[0026] The inner bag 2 includes an inner dust cloth 12, an inner skeleton 7, an inner retaining ring 4, a vibrating motor 10, an electrostatic precipitator fence 3, a pulse type recoil nozzle 6, a base plate 11, and a motor cover 9. Inner dust-removing cloth 12 also adopts materials such as dacron, polypropylene fiber or fiberglass to make, and is sewn into bag shape, and suits on the inner skeleton 7. An inner retaini...

Embodiment 2

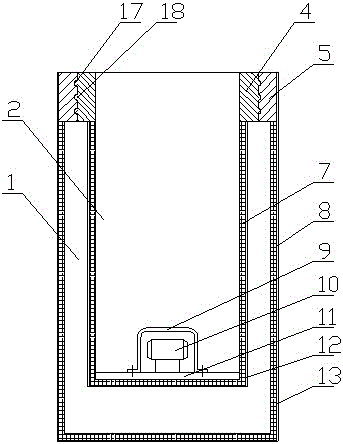

[0037] Such as image 3 As shown, a screw-in double-layer mixed dust bag includes a dust cloth, an inner retaining ring 4, an outer retaining ring 5, an inner frame 7, an outer frame 8, a vibration motor 10, a base plate 11, and a motor cover 9. Inner bag 2 and outer bag 1 are made of dust-removing cloth and inner and outer frame 8 respectively, and inner frame 7 and outer frame 8 are all made grid-like by tiny iron wire, can electrify and carry out electrostatic dust removal. The tops of the inner bag 2 and the outer bag 1 are respectively provided with an inner retaining ring 4 and an outer retaining ring 5, and the outer periphery of the inner retaining ring 4 is provided with a protruding clip 18, and the inner wall of the outer retaining ring 5 is provided with a concave bayonet 17. The clip strip 18 and the bayonet socket 17 can be snapped together. The inner bag 2 and the outer bag 1 are engaged with each other through the clip strip 18 and the bayonet opening 17 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com