Equipment for machining multiple holes of back cover hinge

A hole processing and hinge technology, applied in metal processing equipment, drilling/drilling equipment, metal processing, etc., can solve problems such as low efficiency, large number of series holes, and unguaranteed position accuracy, so as to reduce the work intensity , improve processing efficiency, and ensure the effect of position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

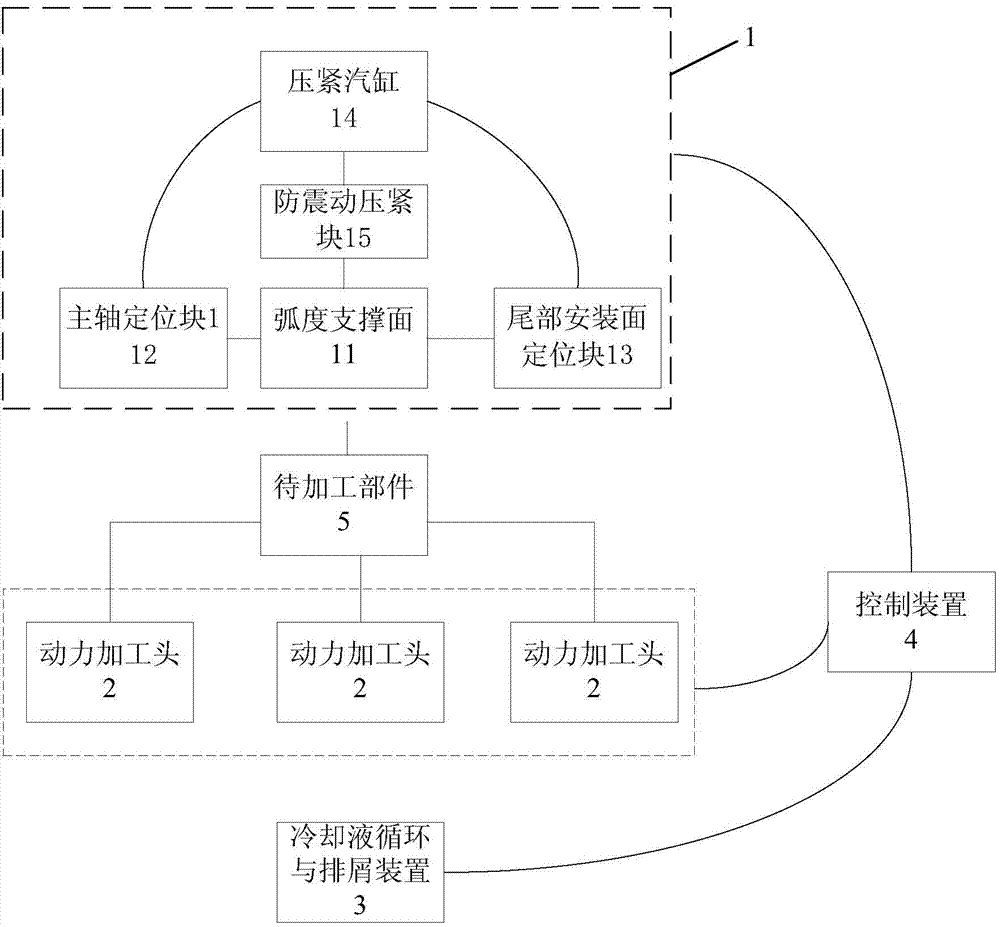

[0021] like figure 1 As shown, a device for multi-hole machining of the back cover hinge includes a component positioning device 1, at least two power processing heads 2, a coolant circulation and chip removal device 3, and a control device 4, and the component to be processed 5 is positioned by the component After the device 1 is fixed, the power processing head 2 is aligned with the hole to be processed in the component 5 to be processed, the coolant circulation and the chip removal device 3 are aligned with the power processing head, and the control device 4 is respectively connected with the component The positioning device 1, the power processing head 2, the coolant circulation and the chip removal device 3 are connected.

[0022] The component positioning device 1 includes a radian support surface 11, a main shaft positioning block 12, a tail mounting surface positioning block 13 and a compression cylinder 14, and the main shaft positioning block 12 and the tail mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com