Electric spindle type torque motor driven A/C double tilt angle numerical control universal milling head

A technology of torque motor and universal milling head, which is applied in the direction of driving device, milling machine equipment, milling machine equipment details, etc., can solve the problems of complex transmission structure, vibration, double swing angle CNC universal milling head system accuracy and stability decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0014] The electric spindle type torque motor drives the A / C double-swing angle CNC universal milling head of the present invention, which is especially suitable for being configured as a power head in a CNC machine tool, improving the configuration of the CNC machine tool, and widely used in high-speed finishing, such as aerospace, high-speed rail trains and other industries High-strength and lightweight material parts such as aluminum alloys, titanium alloys, high-temperature resistant alloys and composite materials.

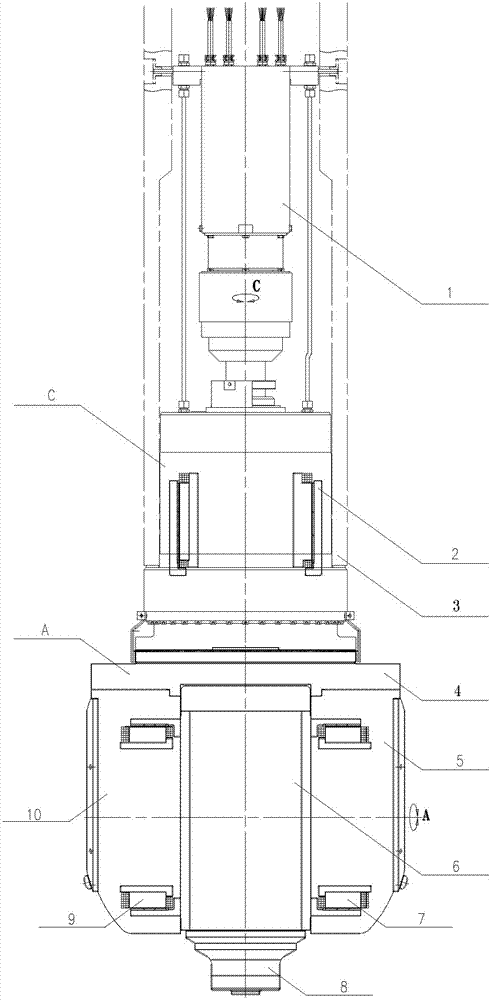

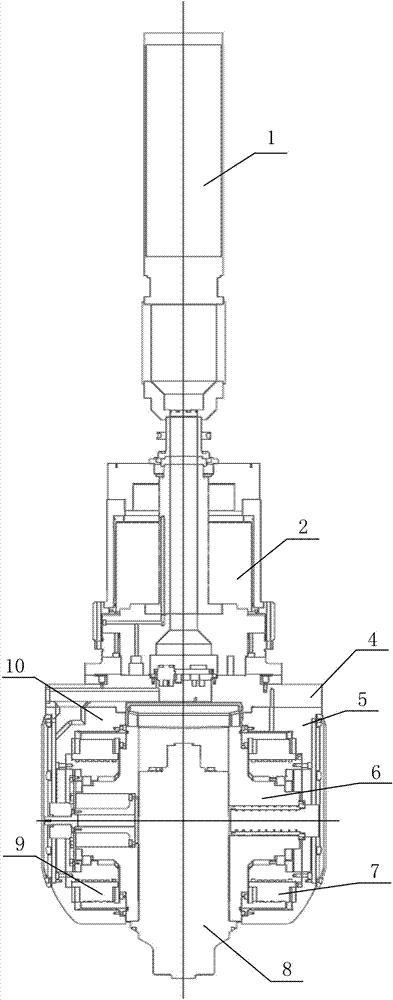

[0015] The electric spindle type torque motor of the present invention drives the A / C double swing angle numerical control universal milling head such as figure 1 As shown, it includes the main shaft installed in the swinging body 6 to clamp the tool and the A-axis assembly supporting the main shaft unit. This part includes the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com