A rotating arc sensor for eutectic pool twin-wire tandem welding

A technology of rotating arc and eutectic pool, applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc., can solve the problems of low cladding rate, difficulty in high-speed and high-efficiency welding, etc., to improve cladding rate and welding heat input Controllable and improve the effect of weld form factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

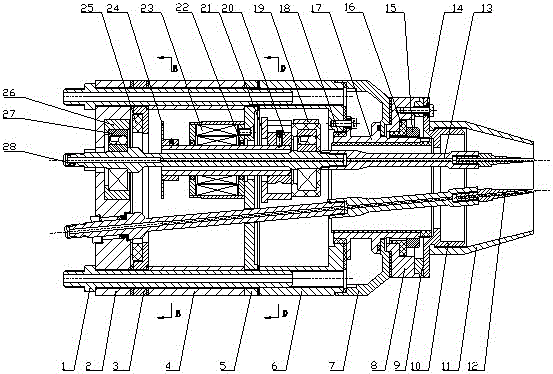

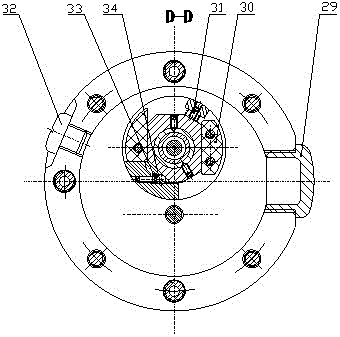

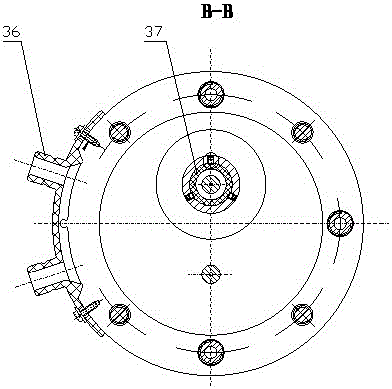

[0039] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the eutectic pool twin-wire tandem welding rotary arc sensor of the present invention includes a driving mechanism, an eccentricity adjustment mechanism, a water and air chamber assembly, a water pipe 1, an upper end cover 2, a stopper fixing cover 3, a middle cavity shell 4, The motor support plate 5, the lower cavity shell 6, the front conductive rod and the trailing conductive rod composed of the upper conductive rod 28, the lower conductive rod 13 and the conductive tip 12, wherein, the upper end cover 2, the stopper fixed cover 3, and the middle cavity shell 4 , the motor support plate 5, and the lower chamber casing 6 are connected by screws; the upper end cover 2 is equipped with a bearing bush 26, and the bearing bush 26 is equipped with a rolling bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com