Twin-screw extrusion device for pitch carbon fiber protofilament spinning device

A twin-screw extrusion, pitch carbon fiber technology, applied in the field of spinning equipment, can solve the problems of inability to take into account the uniformity of the pitch melt flow, reduce production efficiency, etc., and achieve the effects of simple structure, improved production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

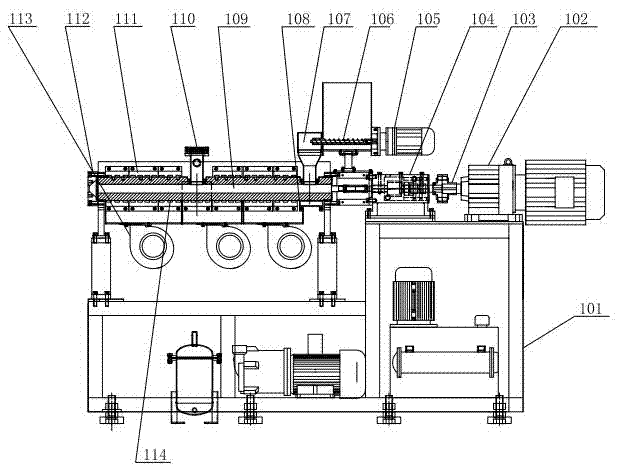

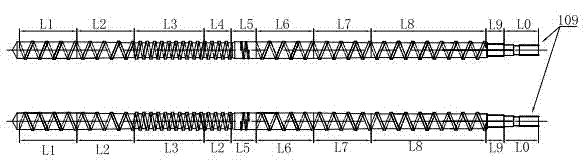

[0016] Such as figure 1 As shown, a kind of twin-screw extruder for pitch carbon fiber precursor spinning device described in the present invention comprises frame 101 and fan temperature control port 113, and speed reducer 102 is installed on the frame 101, and in speed reducer 102 The output end of the twin-screw 109 is connected to the gear box 104 through a coupling 103, one end of the twin-screw 109 is connected to the gear box 104, the other end of the twin-screw 109 is connected to the die head 112, and the outer circumference of the twin-screw 109 is also sleeved with a screw barrel 114, the screw A heating block 111 and a cooling water jacket 108 are installed on the cylinder 114; a cycloidal pinwheel reducer 105 is also included, the output end of the cycloidal pinwheel reducer 105 is connected with the feeding screw 106, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com