Material storage mechanism for organic garbage fully automatic feeding system

An organic waste, fully automatic technology, applied in the direction of garbage conveying, garbage collection, mechanical conveyor, etc., can solve the problems of shortage and increase of investment cost, and achieve the effect of improving productivity, reducing investment cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

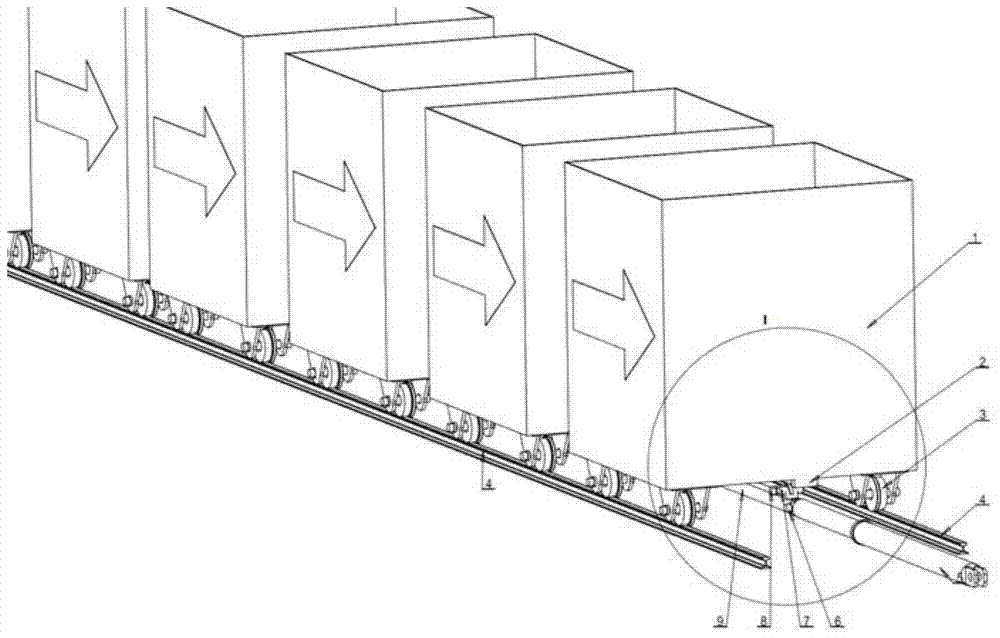

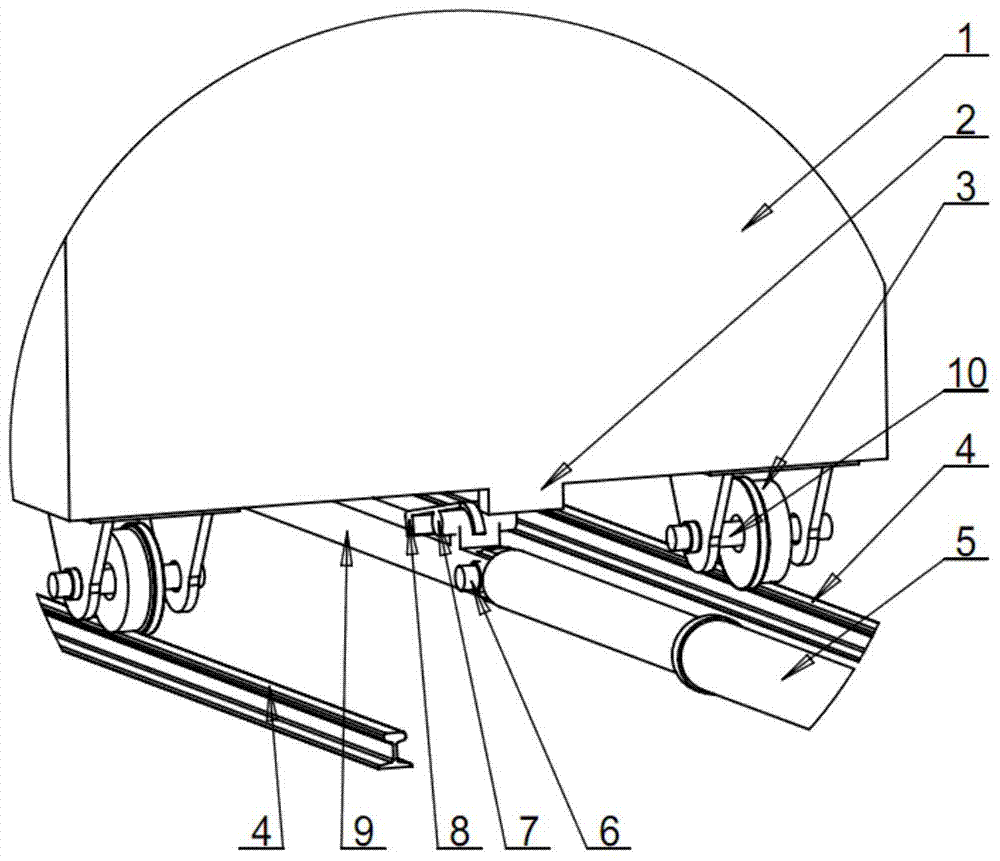

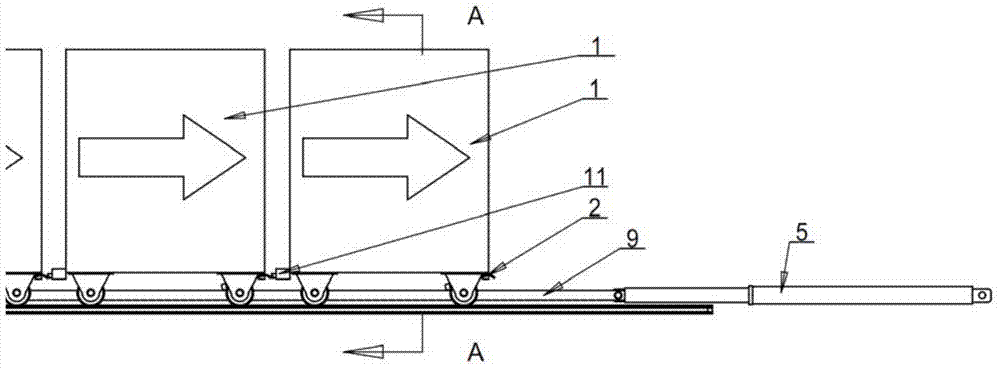

[0022] See Figure 1 to Figure 6 , a storage mechanism for a fully automatic feeding system for organic waste, comprising a plurality of storage boxes 1, the two sides of the bottom plate of the storage box 2 are respectively connected with rollers 3 through wheel shafts 10, and the rollers 3 are set as four single rim rollers, respectively Located at the four corners of the base plate, the rollers 3 are located in the track 4, and the rollers 3 are pressed on two parallel tracks 4 to make the storage box 1 move along the tracks 4, and the rollers 3 are more stable when running on the tracks 4. The traction rail 9 connected with the traction hydraulic cylinder 5 through the coupling head 9-2 and the pin shaft A6 is arranged between the two ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com