Integral oral tube non-PVC membrane full-automatic bag-making filling and sealing machine

An integrated and fully automatic technology, applied in bottling machines, bottle filling, liquid handling, etc., can solve the problems of occupying the space of soft bags for filling medicine, complex mechanism, mixing of medicine liquid, etc., to ensure medical safety and simplify equipment High effect of structure and medical safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

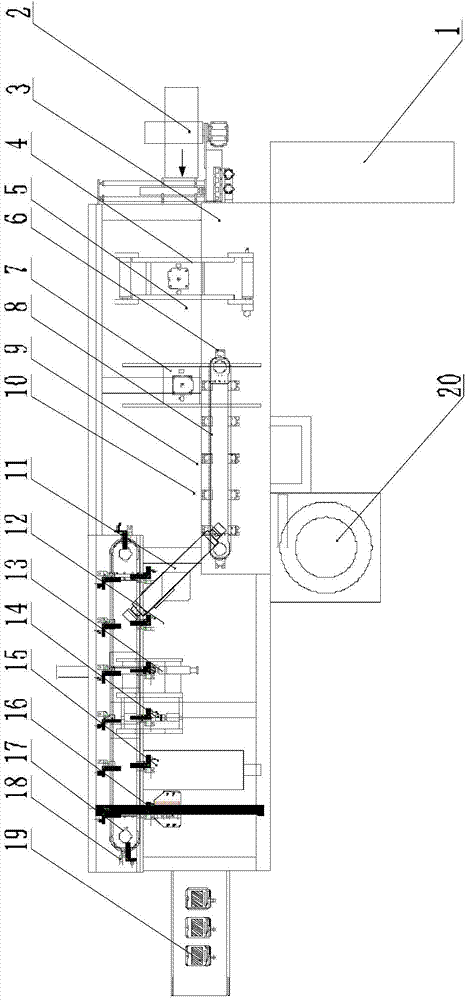

[0094] Please refer to figure 1 , figure 1 The top view of the integrated non-PVC film full-automatic bag making and filling machine provided by the present invention (here, due to the limited space of the drawing, some of the constituent mechanisms are not drawn in detail, and only the lead wires of the reference signs point out the general setting The location, the specific structure see figure 1 other drawings).

[0095] In a specific embodiment, the body of the integrated mouth tube non-PVC film automatic bag making and filling machine provided by the present invention is mainly composed of a frame assembly 3, a power distribution cabinet 1 is arranged on one side of the body, and a film is arranged on the body. Supply mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com