Method for improving doping amount of mining mullock in cement

A technology of mining waste rock and mixing amount, applied in cement production, etc., can solve the problems of high cost, poor economic benefit, unstable cement quality, etc., achieve low cost, stable cement quality, and overcome the effect of unstable cement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

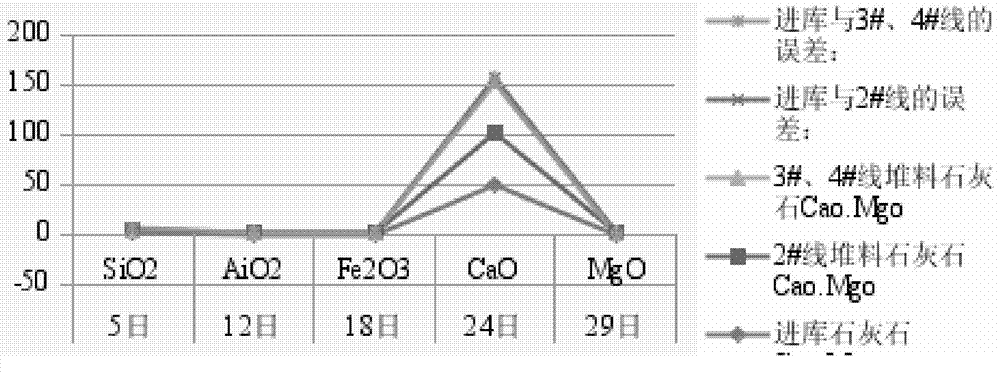

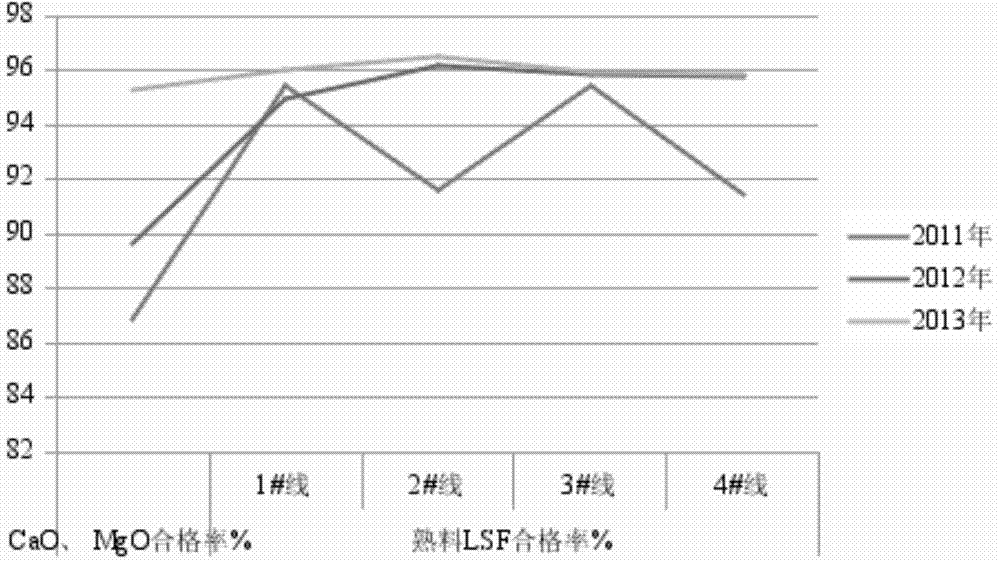

[0045] According to an embodiment of the present invention, such as figure 1 and figure 2 As shown, a method for increasing the amount of mining waste rock mixed in cement is provided, including:

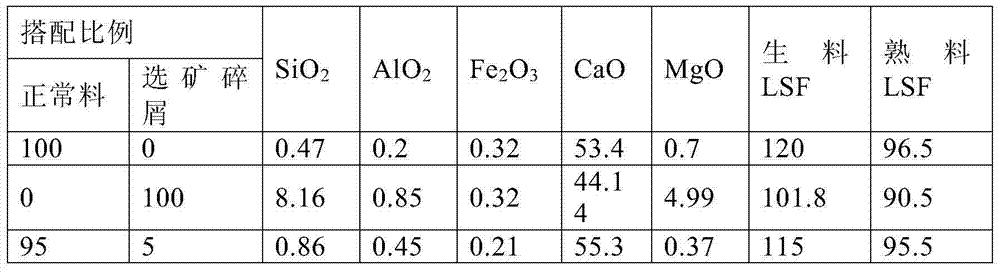

[0046] ⑴Combine mining and dressing waste rocks with limestone in the following parts by weight. The mining and dressing waste rocks include sandstone, iron powder and raw meal:

[0047] Limestone: 88.5 parts;

[0048] Sandstone: 13.8 parts;

[0049] Iron powder: 4.4 parts;

[0050] Raw material: 92 parts;

[0051] (2) Proportionally, the waste rock and limestone from mining and beneficiation are mixed and stirred in the mining area by a hook machine or a loading an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com