Process for preparing Ti662 titanium alloy tube material

A preparation process, titanium alloy technology, applied in the field of preparation process of Ti662 titanium alloy pipe, can solve the problems such as no alloy pipe found, achieve good room temperature and high temperature mechanical properties, high impact strength, high specific strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

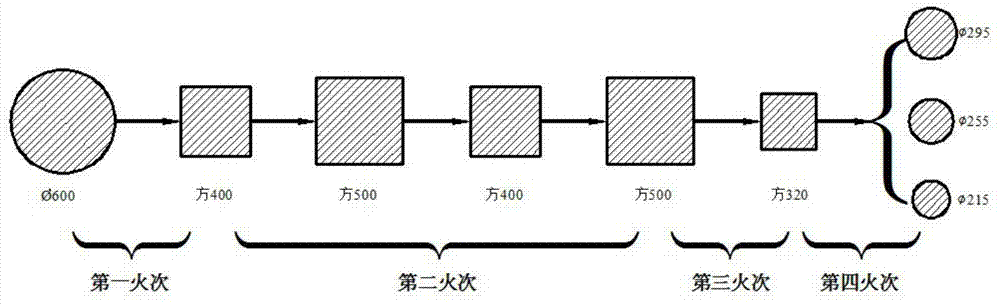

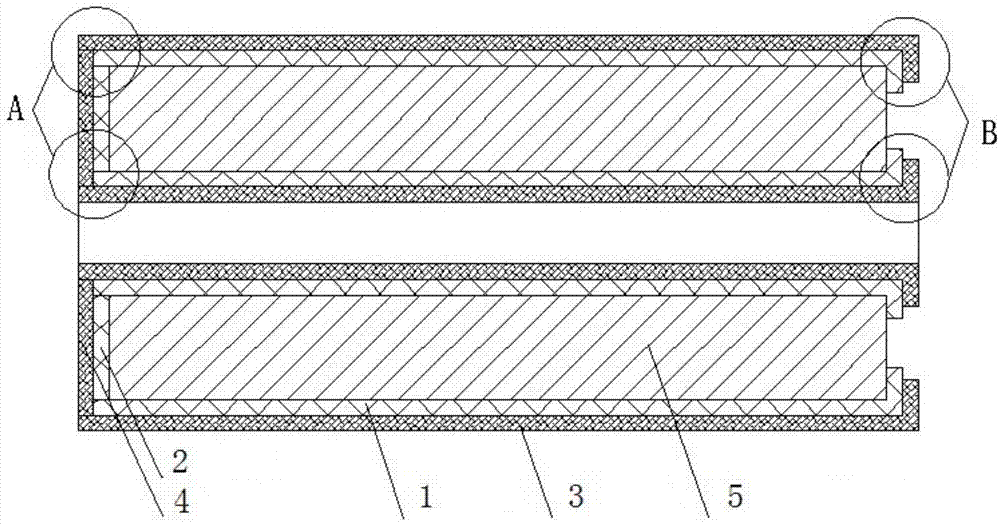

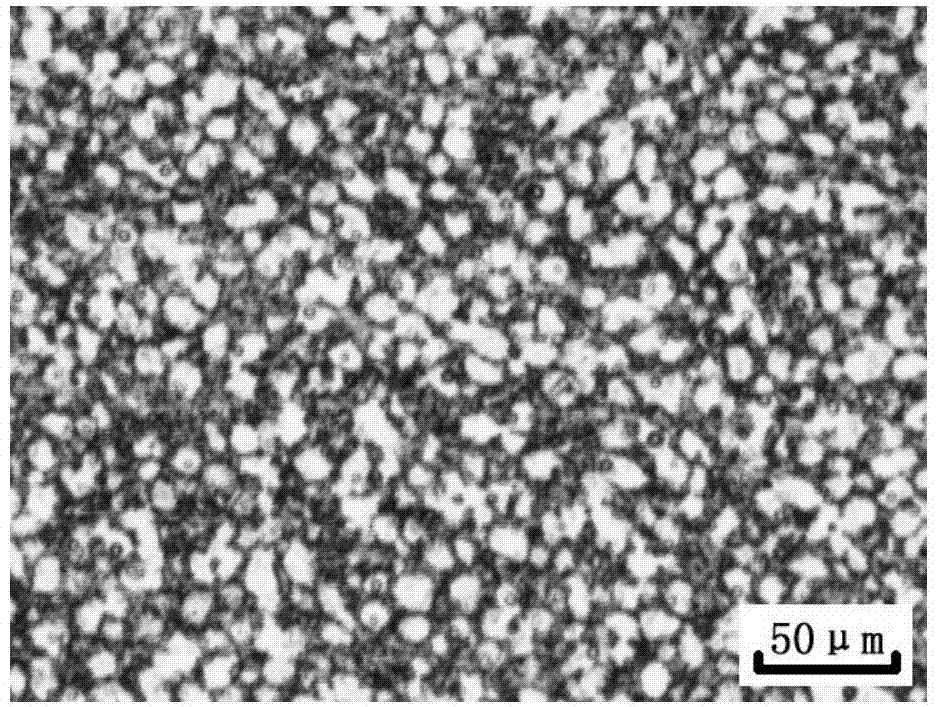

[0057] According to a company's requirements for Ti662 pipes: chemical composition: 5.0≤Al≤6.0%, 5.0≤V≤6.0%, 1.5≤Sn≤2.5%, 0.35≤Cu≤1.0%, 0.35≤Fe≤1.0%, C≤0.05 %, N≤0.04%, H≤0.0125%, O≤0.20%, and the balance is Ti. And other impurity elements +1.5 ×8 ±0.8 ×2600 +10 mm. Surface quality: Surface roughness is less than 3.2μm. Tensile properties at room temperature: tensile strength ≥ 1103MPa, yield strength ≥ 1034MPa, elongation ≥ 10%. Room temperature impact performance: A KU2 ≥9.47J. Tensile properties at 205°C: tensile strength ≥ 931MPa, yield strength ≥ 807MPa, elongation ≥ 13%. Impact performance at 205°C: A KU2 ≥13.56J. Microstructure: The equiaxed α phase is precipitated on the transformed β matrix, or the equiaxed α phase and elongated α phase are precipitated on the transformed β matrix, and the main grain size judged according to ASTM E112 should be grade 6 or higher.

[0058] Concrete preparation process is as follows:

[0059] 1. Ingot preparation:

[0060] Us...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap