Slag removal device and method for lower inserted magnesium electrolytic cell

A magnesium electrolytic cell and residue technology, which is applied in the field of a new type of magnesium electrolytic cell bottom slag removal device, can solve the problems of reduced magnesium collecting chamber space, difficulty in removing residues, and reduced current efficiency, so as to improve electrolysis current efficiency and reduce manual operation intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

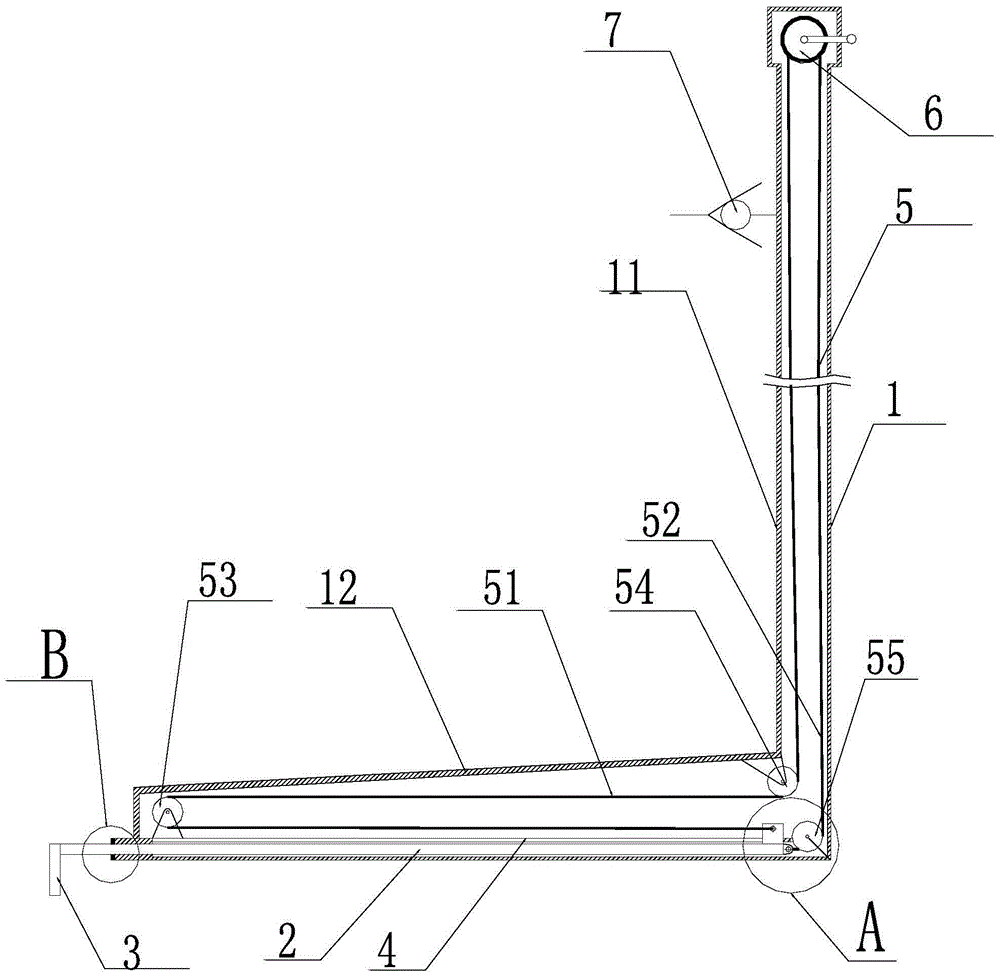

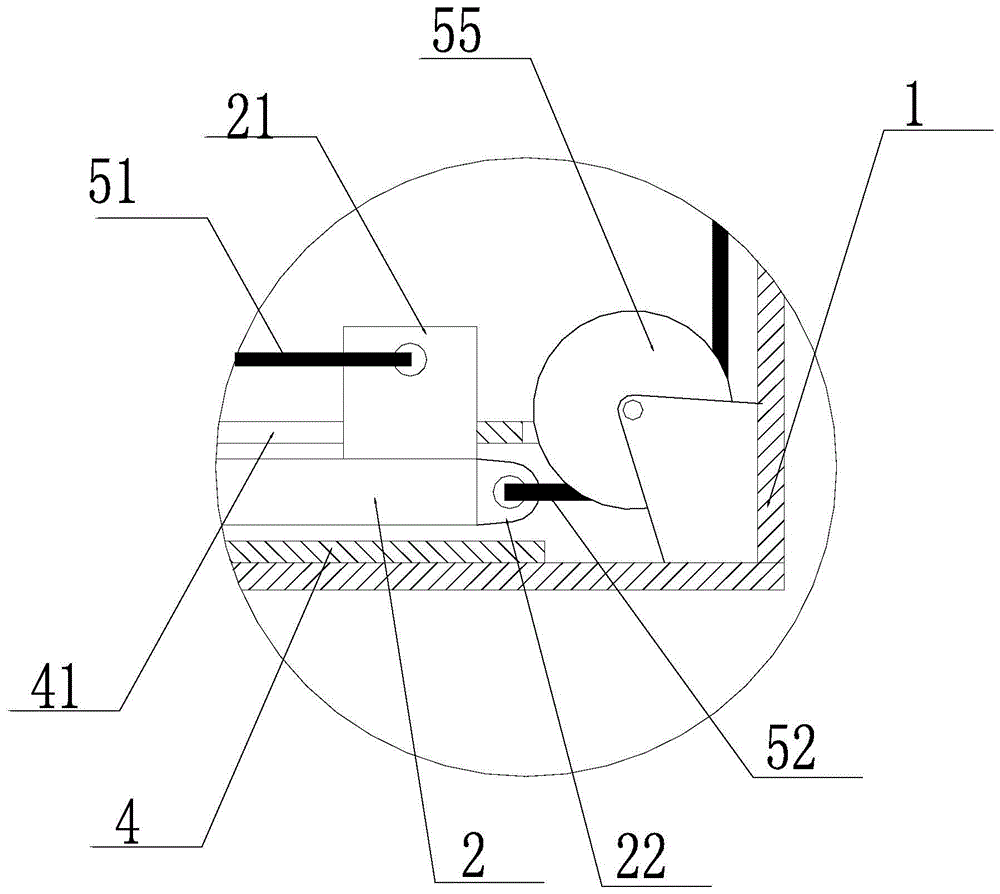

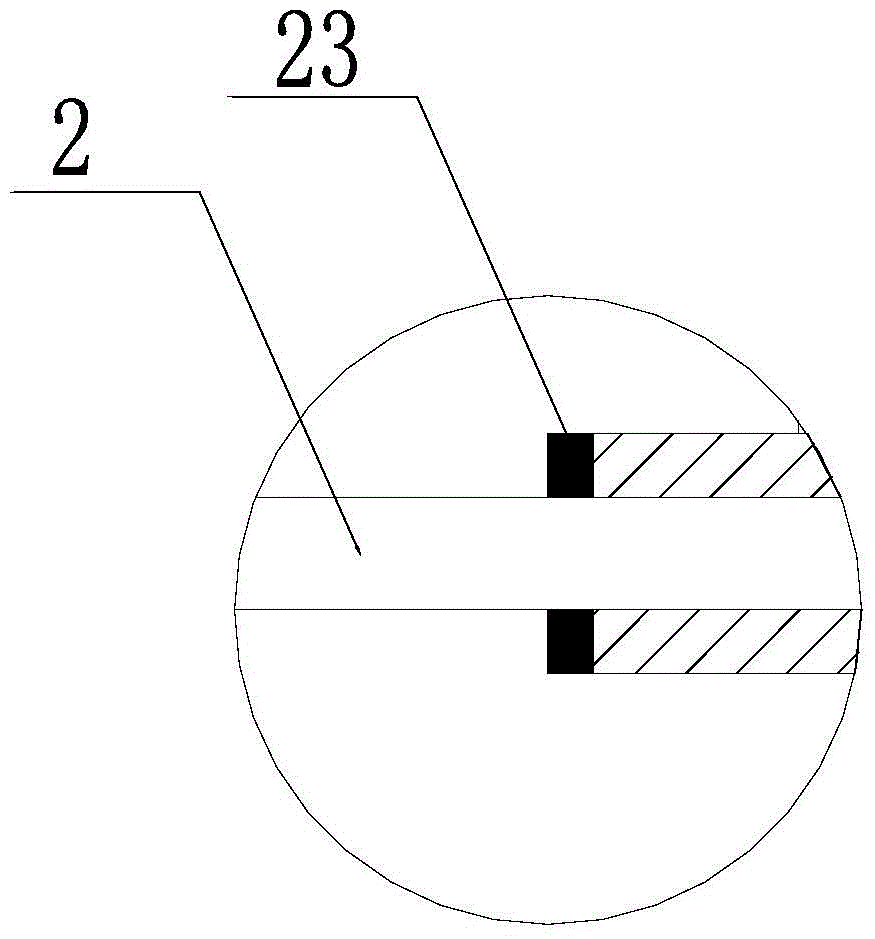

[0026] The slag removal device for the magnesium electrolytic cell inserted under the present invention comprises an L-shaped bracket 1, a push rod 2, a scraper 3 and a guide mechanism 4, the L-shaped bracket 1 includes a supporting means 11 and a working section 12 connected with the supporting means 11, The guide mechanism 4 is arranged on the working section 12, the push rod 2 is arranged in the guide mechanism 4, the scraper 3 is connected to the outer end of the push rod 2, the L-shaped bracket 1 is provided with a pulley system, The push rod 2 is connected with the pulley system, and can perform telescopic movement along the guide mechanism 4 under the drive of the pulley system.

[0027] Among them, the supporting means 11 of the L-shaped bracket 1 is mainly used for hand-held operation, and the working section 12 is mainly used for setting the guide mechanism 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com