Direct twisting machine with lifting yarn balloon adjusting device and balloon adjusting method thereof

A technology of an adjusting device and an adjusting method, which is applied to spinning machines, continuously wound spinning machines, textiles and papermaking, etc., can solve the problem of difficulty in achieving energy saving, inability to achieve optimal balloon shape, and inaccurate control of outer yarn tension. and other problems to achieve the effect of reducing energy consumption, reducing size, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

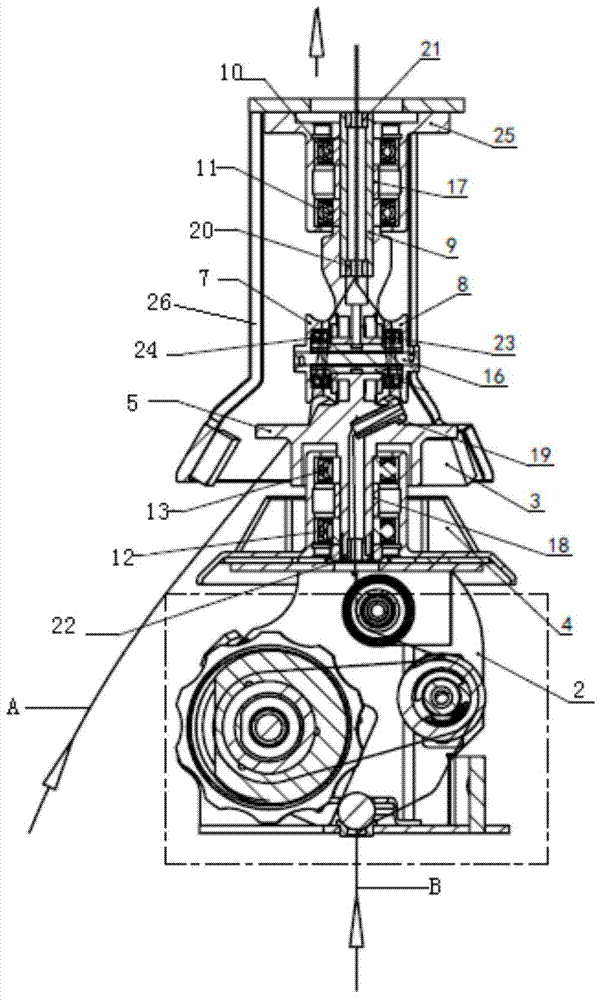

[0038] Such as figure 1 with figure 2 As shown, a direct twisting machine with a lifting type yarn balloon adjusting device includes a direct twisting machine body, and a bracket 1, an even twister, an inner yarn tension device 2, a spindle, and an outer twister mounted on the direct twisting machine body. Yarn tension sensor and control device. The support 1 can move up and down along the main body of the straight twister. The even twister and the inner yarn tension device 2 are both installed on the support 1, and the spindle is located directly under the inner yarn tension device 2.

[0039] The support 1 is composed of a lifting seat and a shield 26. The leveler includes a rotatingly movable leveler support 5 and a bearing seat 25 fitted on the upper part of the leveler support 5. The outer shell of the bearing seat 25 is connected to the lifting seat through a flange. The power of the even twister support 5 for circular motion is provided by the outer yarn A, and the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com