Micro turbine jet engine with two-sided centrifugal pressure roller

A technology of jet engine and micro-turbine, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of increasing air flow, high single-stage pressure ratio, limited engine thrust-to-weight ratio, etc., to increase reliability and life, improve efficiency , the effect of improving reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

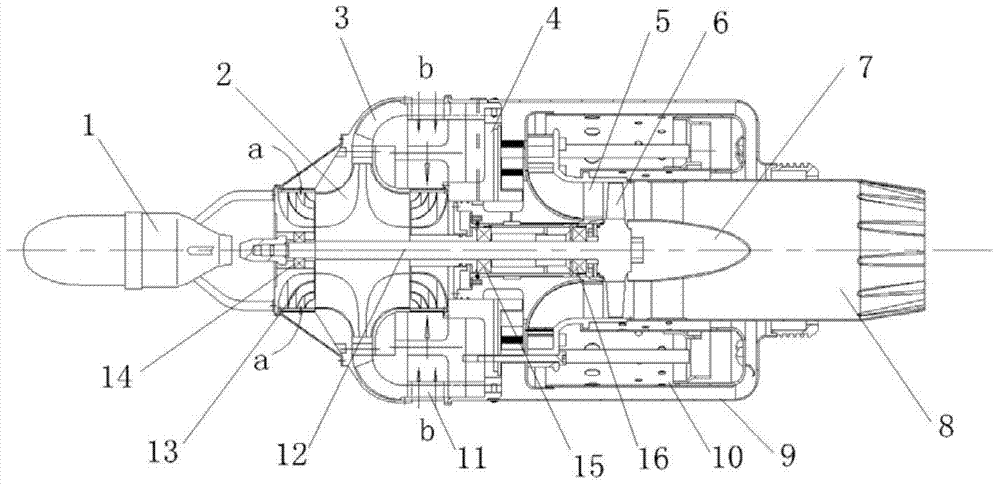

[0011] Such as figure 1 As shown, there is a micro turbojet engine with double-sided centrifugal pressure wheels, which includes a starter motor 1, a double-sided centrifugal compressor 2, a three-dimensional streamlined diffuser 3, an intermediate casing 4, a turbine guide 5, an axial flow turbine 6, Outlet tail cone 7, tail nozzle 8, outer casing 9, combustion chamber 10, front casing 11, rotor shaft 12, intake rectifier 13, auxiliary support 14, first main support 15 and second main support 16, all The axial flow turbine 6 and the rotor shaft 12 are electron beam welded together, the three-dimensional streamlined diffuser 3 is arranged at the outlet end of the double-sided centrifugal compressor 2, and the first main support 15 and the second main support 16 are elastic damping supports.

[0012] The micro-turbojet rotor has double-sided centrifugal pressure wheels and a first-stage axial-flow impingement turbine. Its function is to increase the air flow and eliminate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com