Torsion-transmission helicopter reducer

A split-torque transmission and helicopter technology, applied in the direction of transmission components, transmission devices, transmission device parts, etc., can solve the problem of excessive single-way transmission power, and achieve the effect of simple structure, light weight and small number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

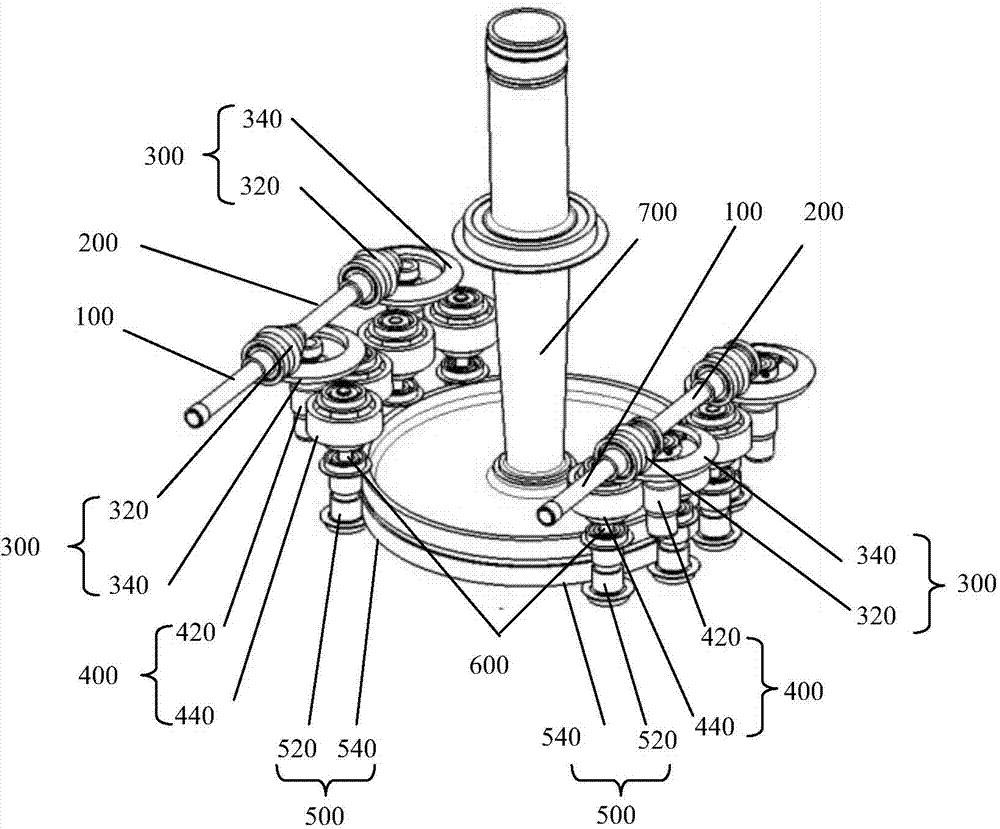

[0020] refer to figure 1 , the preferred embodiment of the present invention provides a split torque drive helicopter reducer, including:

[0021] Reversing gear pair 300, reversing gear pair 300 comprises two driving gears 320 and two driven gears 340 meshing with different driving gears 320 respectively, the transmission ratio of driving gear 320 and driven gear 340 is greater than 1; The driving gears 320 are connected through the power elastic shaft 200 , and one of the driving gears 320 is connected with the power input shaft 100 .

[0022] The cylindrical gear pair 400, the cylindrical gear pair 400 includes a plurality of cylindrical driving pinions 420 and a plurality of cylindrical driven bull gears 440, each cylindrical driving pinion 420...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com